Manufacturing method for high capacity composite electrode of lithium ionic cell

A lithium-ion battery and composite electrode technology, applied in battery electrodes, electrode manufacturing, active material electrodes, etc., can solve the problems of increasing the volume density of electrodes and affecting the first reversible performance of the system, so as to improve cycle stability, reduce process costs, The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

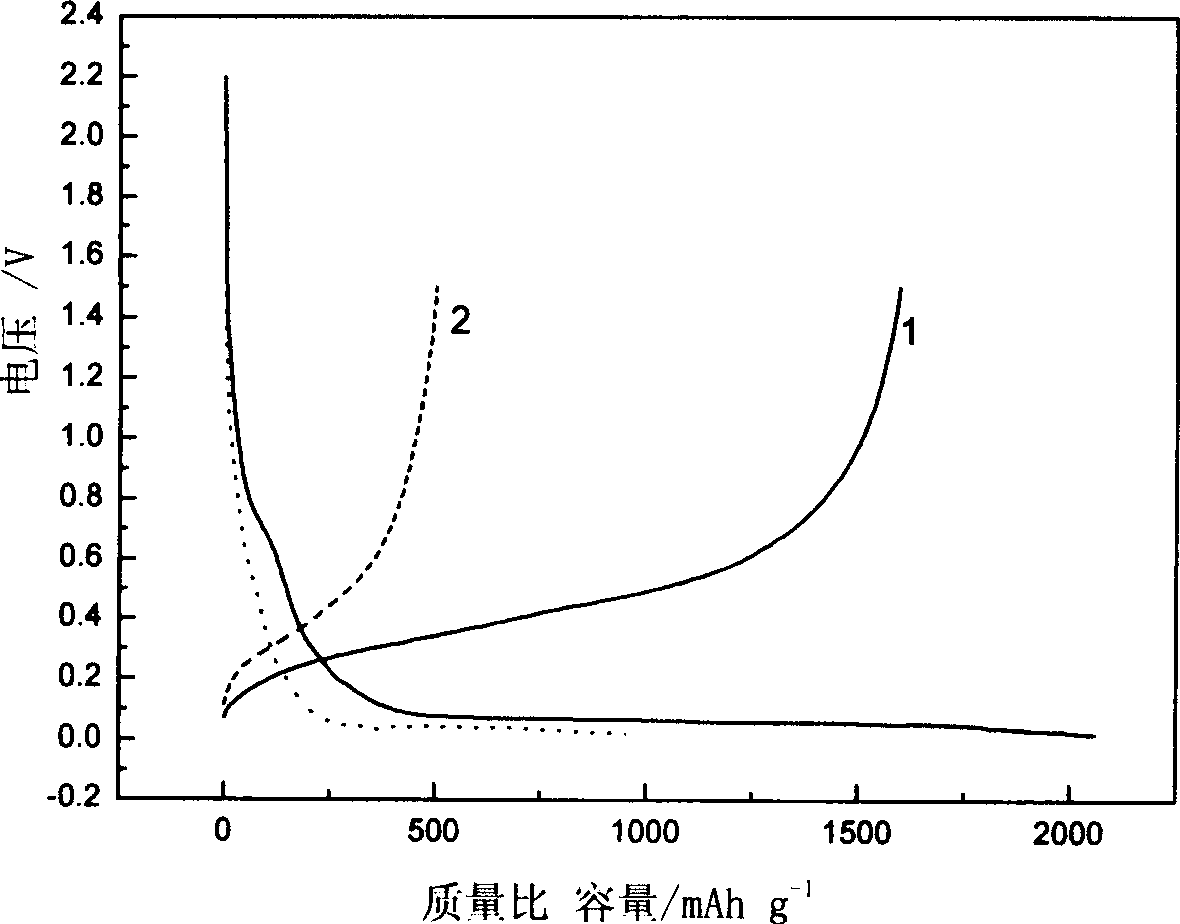

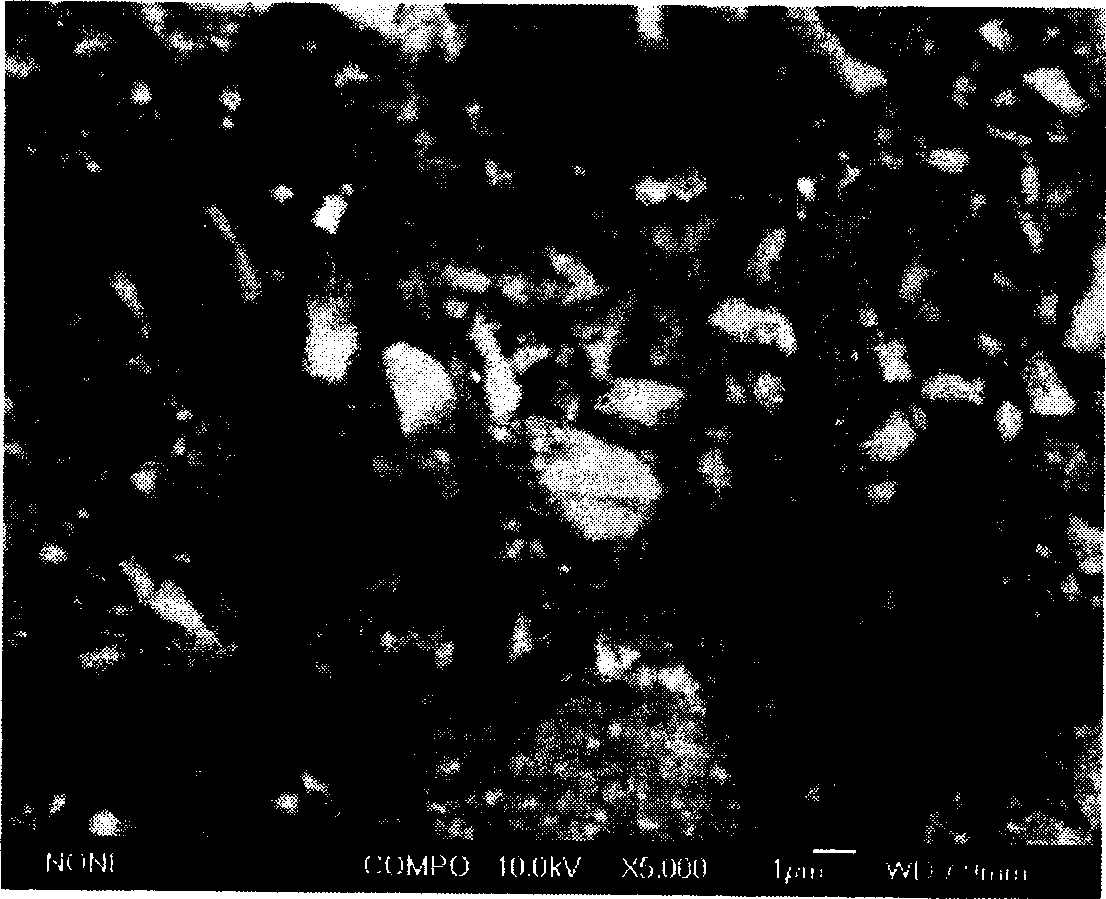

Embodiment 1

[0020] Dissolve asphalt in pyridine evenly, add silicon powder and active graphite powder about 5 microns slowly at a mass ratio of 1:2, stir evenly through magnetic force, heat at 40-60°C to remove organic solvent and place in an oven Dry the sample at about 100°C; the dried mixture is a viscous paste, which is evenly coated on the surface of the foamed nickel, and rolled with a force of 1-2 MPa to fill part of the paste into the pores of the foamed nickel Inside, the precursors for composite electrodes are made. Move this precursor into a sealed quartz tube, and pass in Ar and H 2 Protected by mixed gas, the sealed quartz tube was moved into a heating furnace, and the temperature was slowly raised to 900°C with a heating rate of 15°C / min and a reaction time of 100min. After the reaction, the whole process has been protected by an inert atmosphere. After the reaction, the sample is cooled in a furnace under the protection of an inert gas to become a composite electrode pole...

Embodiment 2

[0022] Dissolve asphalt in tetrahydrofuran evenly, and filter out insoluble blocks; slowly add silicon powder and micron-sized nickel powder with a particle size of less than 100 nanometers into the asphalt solution at a mass ratio of 1:4, stir evenly through magnetic force, and pass through 40 to 60 Heat at ℃ to remove the organic solvent and dry the sample in an oven at 100℃; the dried mixture is a viscous paste, which is evenly coated on the surface of the foamed nickel, and passed through a 1-2MPa force roller Pressing, so that part of the paste is filled into the pores of the nickel foam to make the precursor of the composite electrode. Move this precursor into a sealed quartz tube, and pass in Ar and H 2 Under the protection of mixed gas, the sealed quartz tube was moved into a heating furnace, and the temperature was slowly raised to 800°C with a heating rate of 15°C / min and a reaction time of 100min. After the reaction, the sample is cooled in a furnace under the prot...

Embodiment 3

[0024] Dissolve the asphalt in acetone evenly, and filter out the insoluble block; slowly add silicon powder and reduced iron powder of about 1 micron into the asphalt solution at a mass ratio of 1:4, stir evenly by magnetic force, and heat at 40-60°C. Remove the organic solvent and dry the sample in an oven at 100°C; the dried mixture is a viscous paste, which is evenly coated on the surface of the foamed nickel, and rolled with a force of 1 to 2 MPa to make Part of the paste is filled into the pores of the nickel foam to make the precursor of the composite electrode. Move this precursor into a sealed quartz tube, and pass in Ar and H 2Mixed gas protection, the sealed quartz tube is moved into the heating furnace, and the temperature is slowly raised to about 1000 ° C, the heating rate is 20 ° C / min, and the reaction time is about 100 min. After the reaction, the sample is cooled in a furnace under the protection of an inert gas to become a composite electrode pole piece. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com