Method for preparing silver/carbon nano composite body

A carbon nano-composite technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as poor stability of nano-silver, and achieve the effects of stable silver nanoparticles, simple and easy method, and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

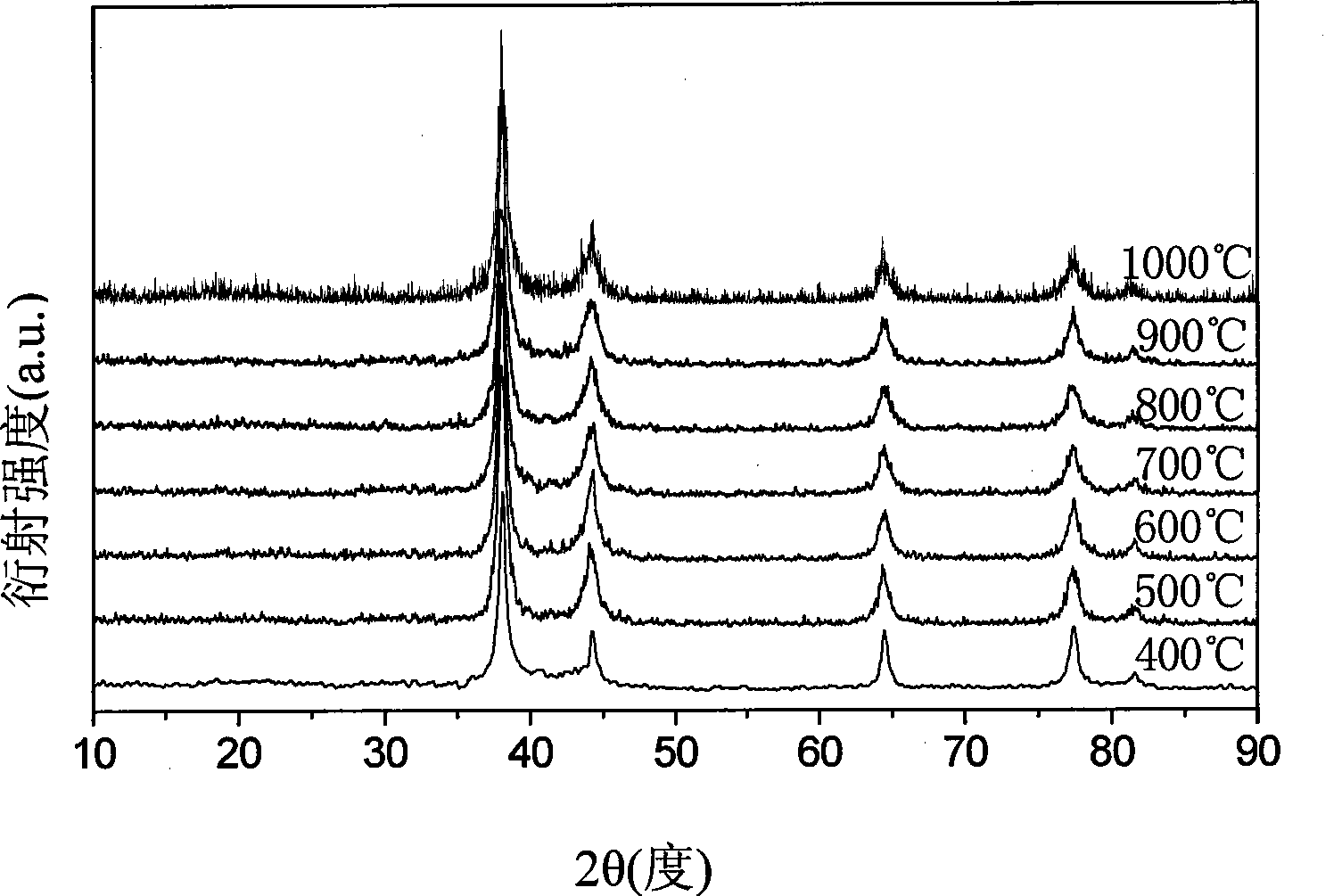

[0008] Specific embodiment one: the present embodiment silver / carbon nanocomposite is prepared according to the following steps: 1, carbon source and silver ion coordination: carbon source and silver nitrate aqueous solution or silver ammonia solution are mixed, then add metal catalyst solution, stir 12 ~24h, then sonicate for 30~120min, add surfactant solution to the mixture, and continue to stir for 1~3h; 2. Complex solidification: vacuum dry the mixture prepared in step 1 at 20~100°C for 2~24h, Then cool to room temperature; 3. Heat treatment: heat up to 400-1100°C at a rate of 5-20°C / min, and then heat the product of step 2 under the condition that the air flow is 60-250ml / min and the temperature is 400-1100°C. Heat treatment for 0.5-6h; 4. Activation treatment: heat up to 200-500°C at a rate of 1-20°C / min, and then heat up to 200-500°C with an air flow rate of 60-300ml / min and a treatment temperature of 200-500°C. The product is activated for 3 to 6 hours to obtain a silv...

specific Embodiment approach 2

[0011] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the carbon source in step 1 is a polymer with polar groups, agricultural and forestry crop extracts or agricultural and forestry waste; wherein the polymer with polar groups One or more of polymethacrylic acid, polystyrene, polyfurfuryl alcohol, polyacrylamide, polyimide, polyurethane, polyglucosamine, polyethylene glycol, anion and cation exchange resins, polyvinyl alcohol, polyaniline The agricultural and forestry crop extracts are glucose, sucrose, fructose or starch, and the agricultural and forestry wastes are sugar beet bagasse, bagasse, corn stalks, reeds, cattail grass or wormwood. Others are the same as in the first embodiment.

[0012] In this embodiment, when there are two or more polymers with polar groups, the components are mixed in any proportion.

specific Embodiment approach 3

[0013] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the metal catalyst solution in step one is ferric sulfate solution, ferrous sulfate solution, ferric chloride solution, ferrous chloride solution, ferric nitrate solution, Ferrous nitrate solution, potassium ferricyanide solution, potassium ferrocyanide solution, potassium ferrioxalate solution, cobalt sulfate solution, cobalt nitrate solution, cobalt acetate solution, cobalt chloride solution, nickel chloride solution, nickel nitrate solution, nickel acetate solution, nickel sulfate solution, magnesium chloride solution, magnesium nitrate solution, magnesium sulfate solution, magnesium acetate solution or magnesium carbonate solution. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com