Preparation of high tenacity nanocrystalline silicide coating

A silicide layer, nanocrystal technology, used in coatings, metal material coating processes, ion implantation plating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

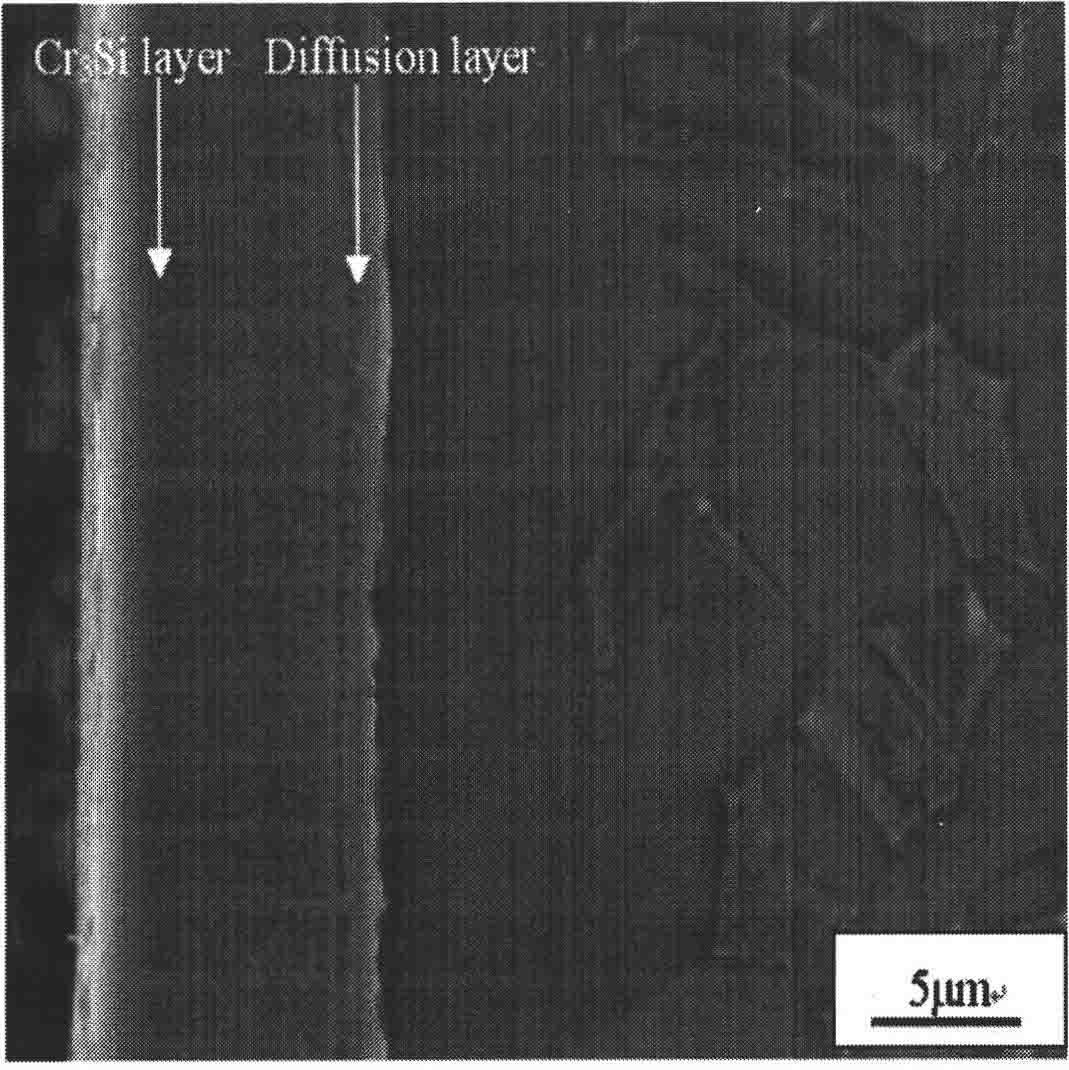

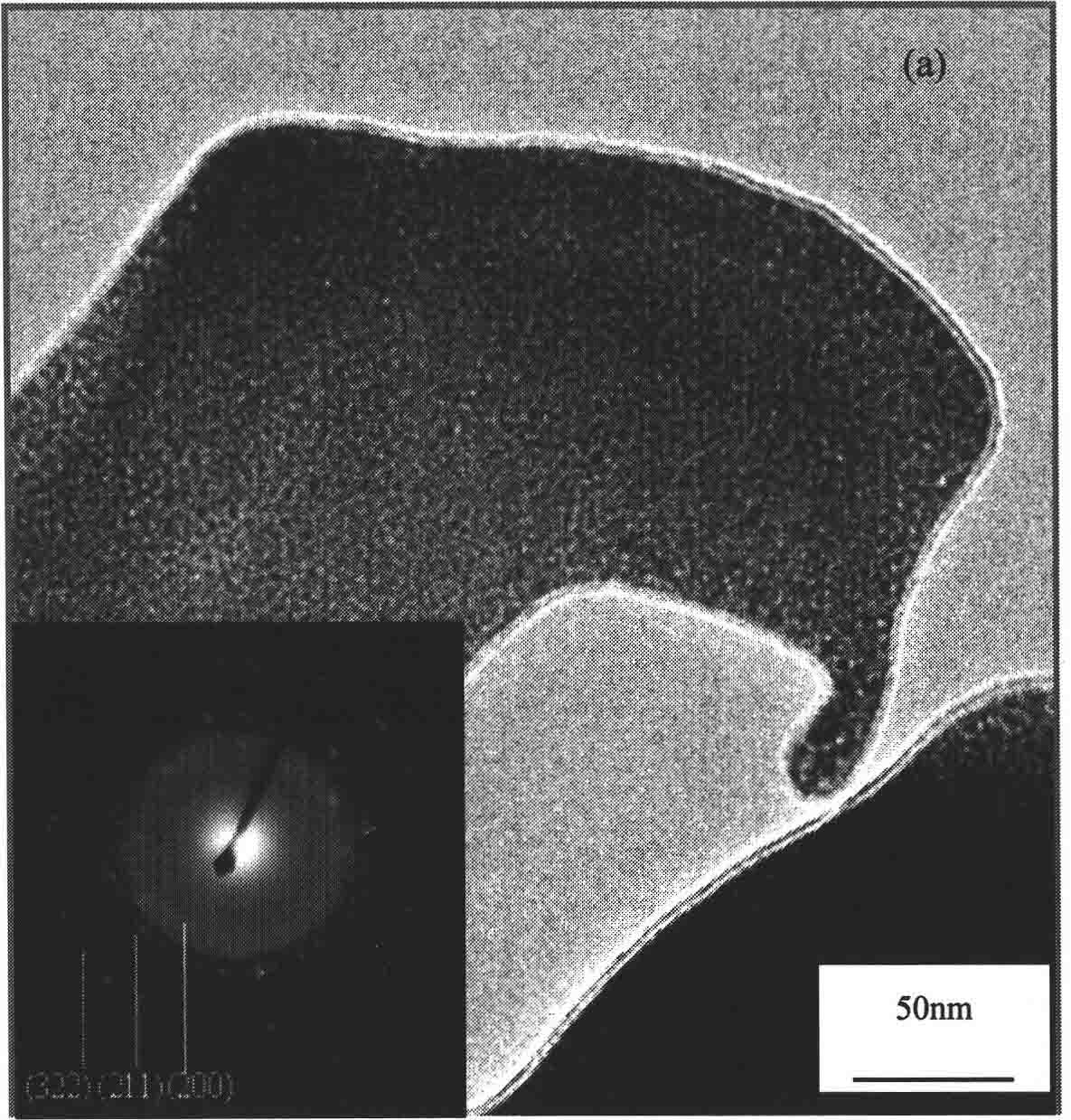

[0026] figure 1 The composition ratio of Cr: Si = 1: 1 powder metallurgy sintered plate prepared by the hot isostatic pressing process is used as the target material, and the nanocrystalline Cr formed on the surface of the TC4 titanium alloy 3 SEM (scanning electron microscope) photograph of Si coating. figure 2 For the nanocrystalline Cr 3 Transmission electron micrographs of the Si coating. Observation by transmission electron microscope can prove that the coating is nanocrystalline, and its grain size is less than 5nm. Nanocrystalline Cr 3 The hardness of the Si coating is 28GPa, the elastic modulus is 357GPa, and the bonding force between the coating and the substrate is 80N. The evaluation of the toughness of the coating by the indentation method showed that no cracks were observed around the microhardness indentation when the indentation load was 200g and 300g, while the coarse-grained Cr 3 Cracks appear around the microhardness indentation of Si material when the ...

example 2

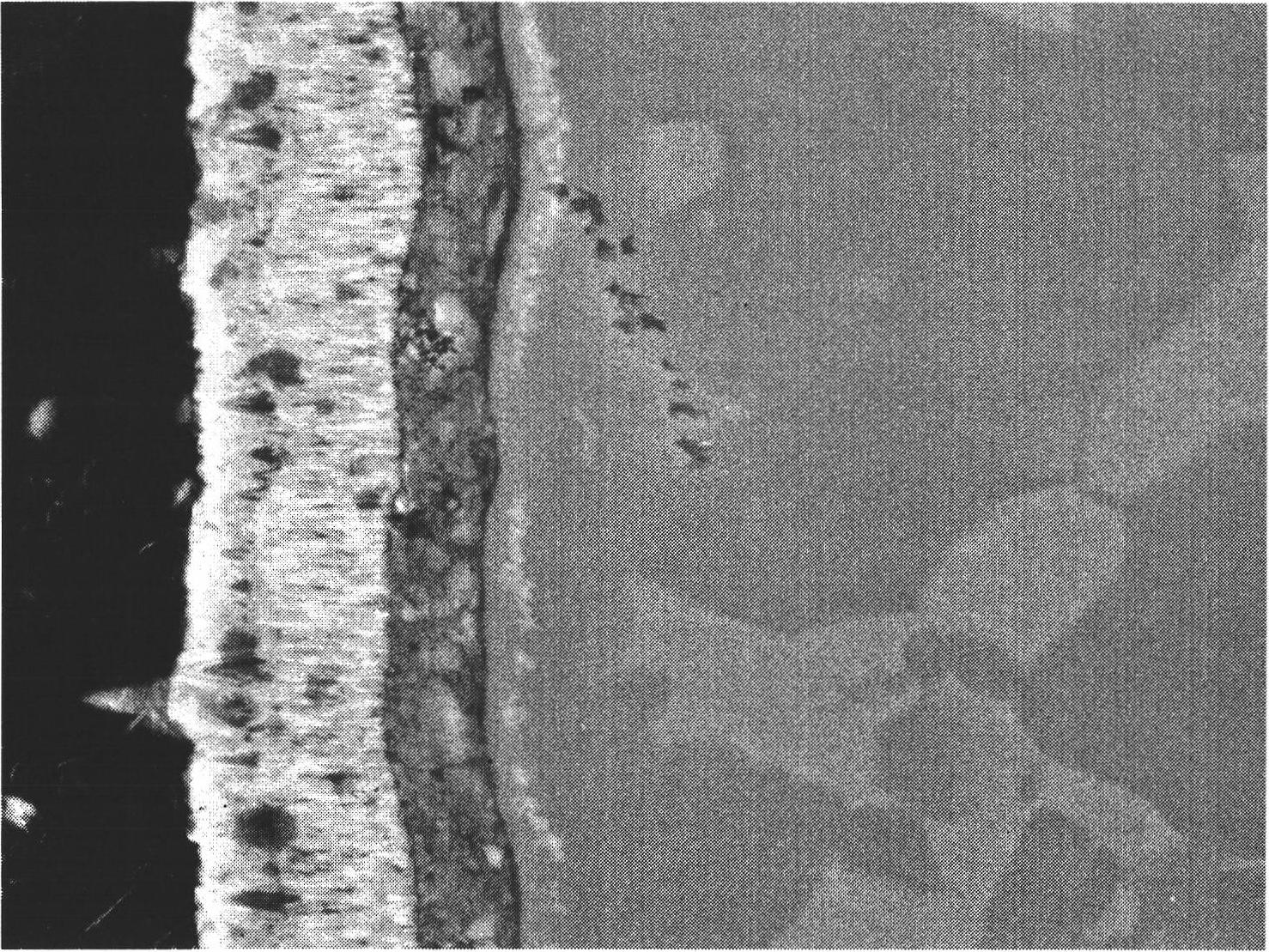

[0028] image 3 The composition ratio of Ni: Si = 1: 1 powder metallurgy sintered plate prepared by the hot isostatic pressing process is used as the target material, and the nanocrystalline NiSi formed on the surface of the TC4 titanium alloy 2 SEM photograph of the coating. figure 2 For the nanocrystalline NiSi 2 TEM photograph of the coating. The results of wear experiments at room temperature and high temperature show that: nanocrystalline NiSi 2 The specific wear rate of the coating has little change with the increase of load and temperature, which indicates that the wear of the coating is not sensitive to load and temperature. Compared with TC4 alloy, nanocrystalline NiSi 2 / Ti 5 Si 3 The specific wear rate of the composite coating is reduced by more than 2 orders of magnitude. Nanocrystalline NiSi 2 The coating has a higher pitting potential (1.5V), which is obviously higher than that of TC4 alloy (1.2V). For another corrosion evaluation standard dimension pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com