Strippable ultrathin transfer carrier metal foil and method of manufacturing the same

A technology for transferring carrier and ultra-thin metal, applied in the field of metal foil, can solve the problems of difficult large-scale production and use of ultra-thin copper foil, unsatisfactory, difficult to produce copper foil, etc., and achieves low production cost, high production efficiency, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

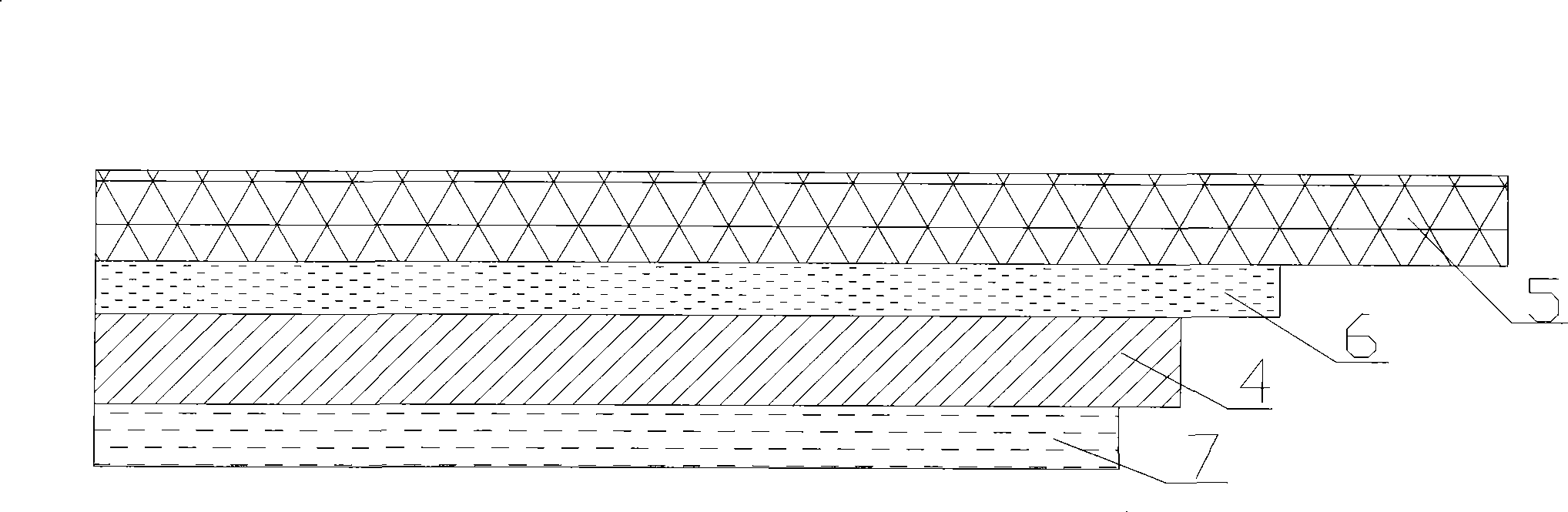

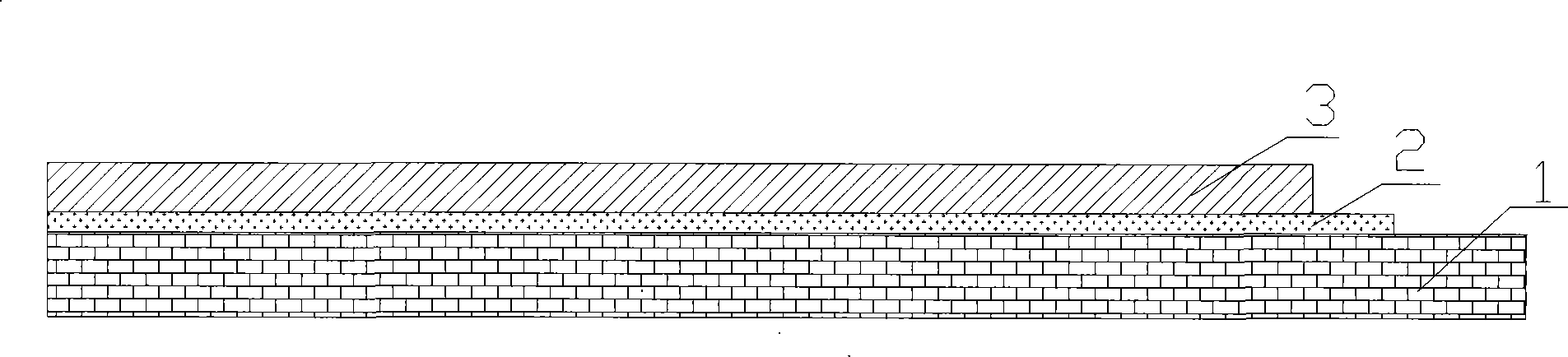

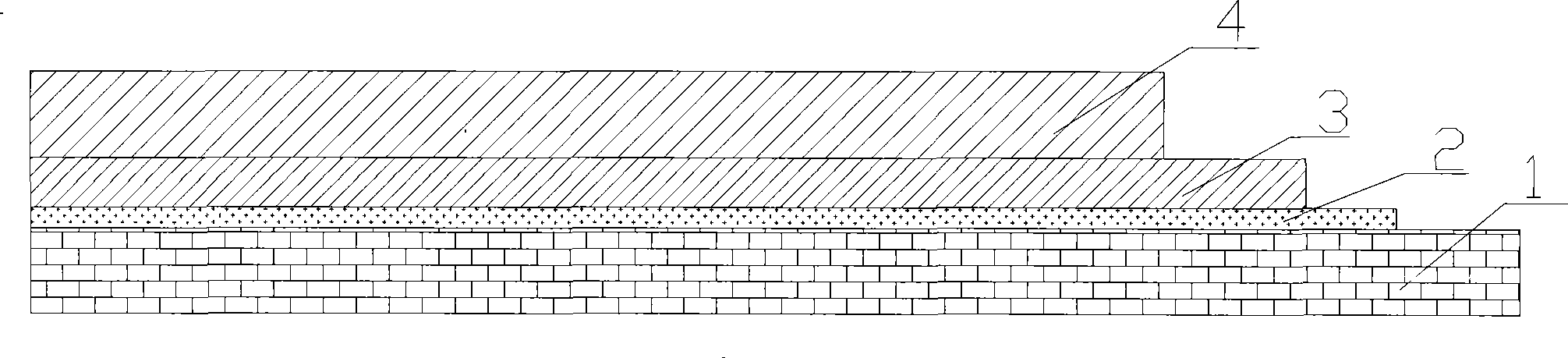

Embodiment 1

[0041] The base layer is made of PET, and the surface of the PET is treated so that the surface tension after treatment is 40-90 dynes. The surface treatment can be corona, chemical treatment and / or ion source treatment. Among them, the process conditions of the ion source treatment can be: in the vacuum degree of 3.0 × 10 -1 ~1.0×10 -3 In the vacuum state of pa, the argon flow rate is 10-1000SCCM, the electron energy range is 100-1500ev, and the processing time is 1-30 minutes. Vacuum roll-to-roll sputtering metal nickel layer on PET surface, the process conditions are: vacuum degree (or absolute pressure value) 0.1 ~ 1Pa, voltage: -300V ~ -600V (DC), current: 50 ~ 200A, argon flow: 100~500sccm, baseband speed: 0.1~1.5m / min, surface conductivity of nickel metal layer is 1 ohm~20 kohm, adhesion is 0.4-0.9 kg. Brightening treatment is carried out on the surface of the metal nickel layer to form a bright metal layer on the surface, making the surface as bright as a mirror, an...

Embodiment 2

[0043]The surface treatment process of PEI, PEN or aluminum foil is the same as that of PET. The preparation of the bright base carrier tape was the same as in Example 1. The difference is the process of electrodepositing ultra-thin copper foil. The process of electrodepositing ultra-thin copper foil is as follows: copper pyrophosphate 50-80g / l, methyl pyrophosphate 250-350g / l, ammonium citrate 20-30g / l electrolyte, pH=8.0-8.5. The working temperature is 30~50℃, and the current density is 0.5~1.0A / dm applied to the bright substrate carrier tape 2 DC current, tape running speed 0.5-15m / h, after at least one level of water washing, after washing, dry with hot air at 50-80°C to form peelable ultra-thin copper foil 4 on the bright substrate carrier tape.

[0044] The invention realizes the large-scale production and use of the 0.1-9 micron ultra-thin copper foil, and has broad market prospects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com