Method for preparing tin reduced nano titanic oxide catalyst

A nano-titanium dioxide and catalyst technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult industrialization, complex process conditions, and long time consumption, and achieve significant photocatalytic activity. Improved separation efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

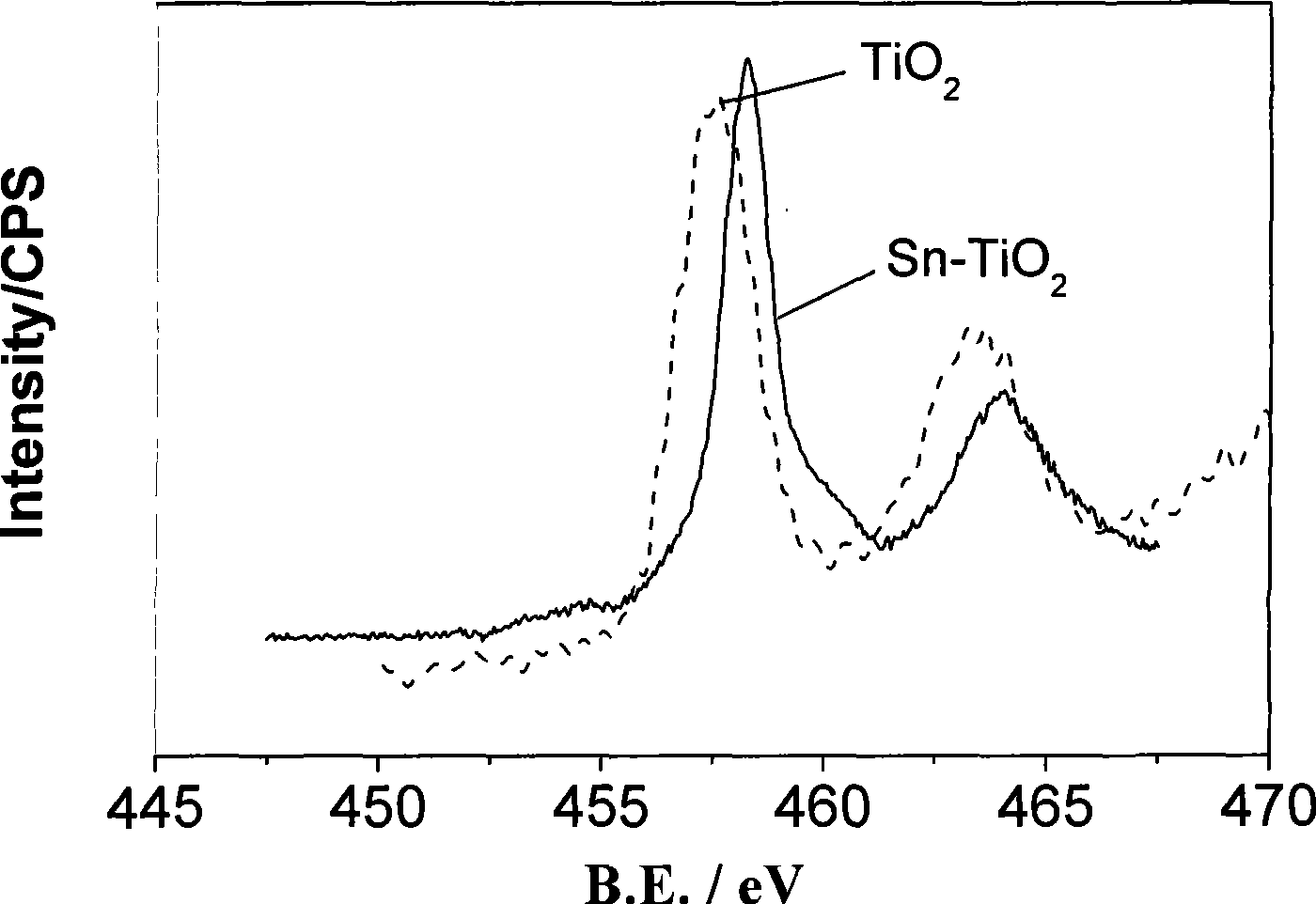

[0020] The preparation method of tin-reduced nano-titanium dioxide catalyst comprises: weighing 1-100 parts of nano-titanium dioxide powder according to the ratio of parts by weight, adding the nano-titanium dioxide powder into the solution of stannous dichloride at room temperature, dipping After 1-60 minutes, filter with suction, wash with water three times, and dry to obtain a tin-reduced nano-titanium dioxide catalyst. The reduction method used is the chemical reduction method of divalent tin.

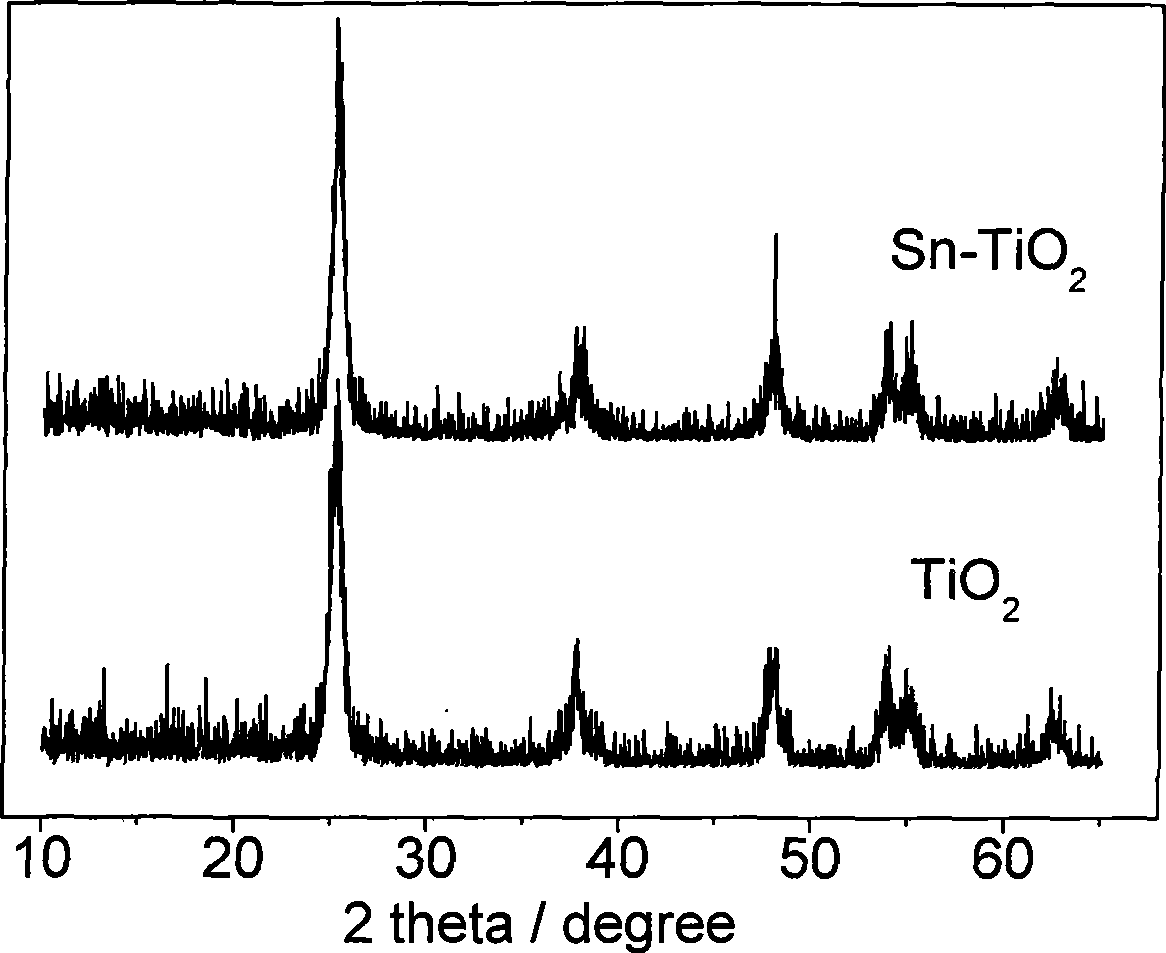

[0021] In the preparation method of the tin-reduced nano-titanium dioxide catalyst, the nano-titanium dioxide powder is composed of one or more of anatase phase, rutile phase, and brookite phase, and the weight of the nano-titanium dioxide powder is 1-100 g / L.

[0022] In the preparation method of the tin-reduced nano-titanium dioxide catalyst, the concentration of the stannous dichloride solution is 0.1-5mol / L, the volume fraction of the stannous dichloride solution is 0.1-1 part,...

Embodiment 2

[0024] Nano titanium dioxide powder was prepared by sol-gel method. Add 10mL of ethanol to a beaker, then slowly drop 7.6mL of tetrabutyl titanate into the ethanol under vigorous stirring, the above mixed solution is electromagnetically stirred for 2 hours, then add 1-5mL of double distilled water and continue to stir until a gel is formed . The gel is dried at 100°C and calcined at 400°C to obtain anatase phase nano titanium dioxide powder with a particle size of 10-30nm.

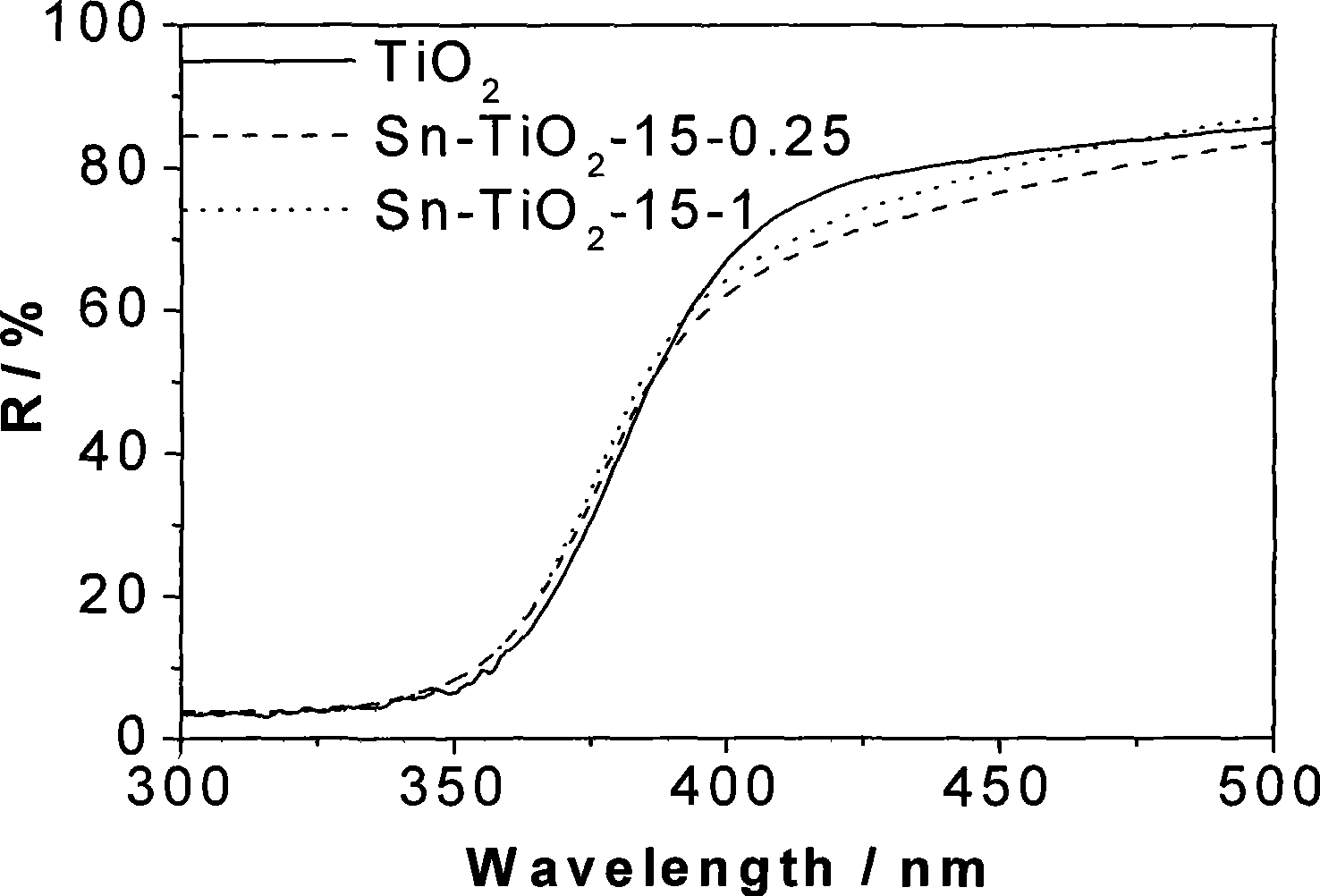

[0025] Prepare a tin protochloride solution with a concentration of 0.1-5 mol / L, weigh 1.0 g of the above-prepared nano-titanium dioxide powder and add it to 50 mL of a stannous chloride solution with a concentration of 0.1-5 mol / L and immerse it for 1-60 minutes, then Suction filter and wash three times with distilled water. Then transfer to a Petri dish and dry at 100°C for 2 hours. Take out and grind to obtain a series of Sn-reduced nano titanium dioxide powders. Respectively named: Sn-TiO 2 -A-B, ...

Embodiment 3

[0030]Nano titanium dioxide powder was prepared by hydrothermal method. Take a dropping funnel and add 30mL of tetrabutyl titanate and 4mL of isopropanol respectively, and mix well. Take a 250mL three-necked bottle and add 120mL of secondary water, add 2mL of nitric acid to adjust the pH to about 1, and use an ice-water cooling bath to control the reaction temperature below 5°C. The solution of tetrabutyl titanate and isopropanol was slowly added dropwise into the three-neck flask under electric stirring (the dropping time takes about 1 hour, and the whole process is completed in an ice-water bath). After the dropwise addition was completed, the temperature was raised to reflux for 2 hours. After the reflux is completed, cool to room temperature and separate layers, use a separatory funnel to remove the milky white liquid in the lower layer, adjust the pH value to 3-12 with ammonia water, then add it to a hydrothermal kettle for 2-48 hours at 180°C for hydrothermal reaction, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com