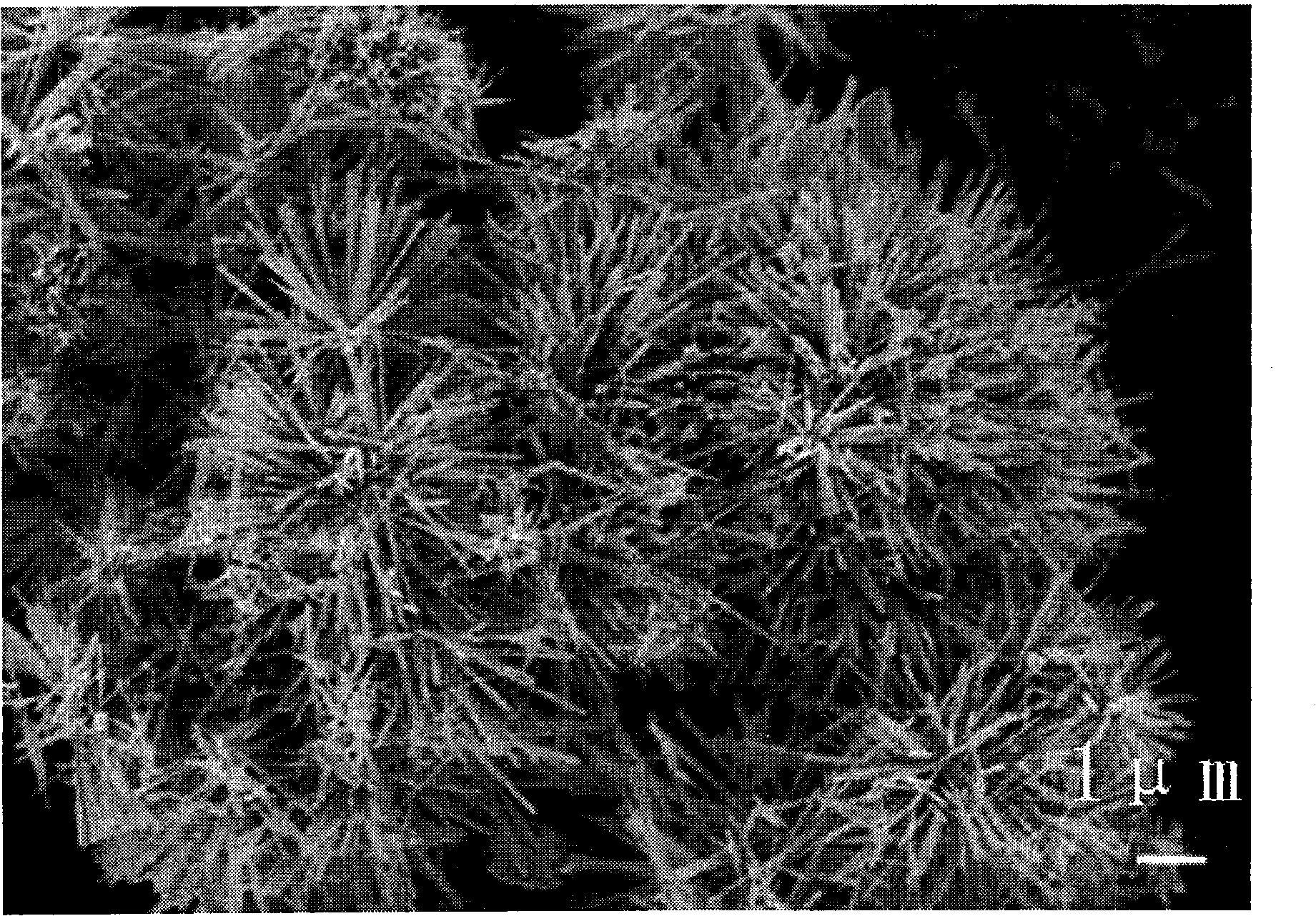

Method for preparing white needle-shaped six-edge mono-crystalline nano-zinc oxide

A single-crystal nanometer and zinc oxide technology, which is applied in chemical instruments and methods, zinc oxide/zinc hydroxide, single crystal growth, etc., can solve problems such as difficult matching of coexisting substances, irregular product morphology, and limited application. Achieve the effects of high output rate, pure color and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

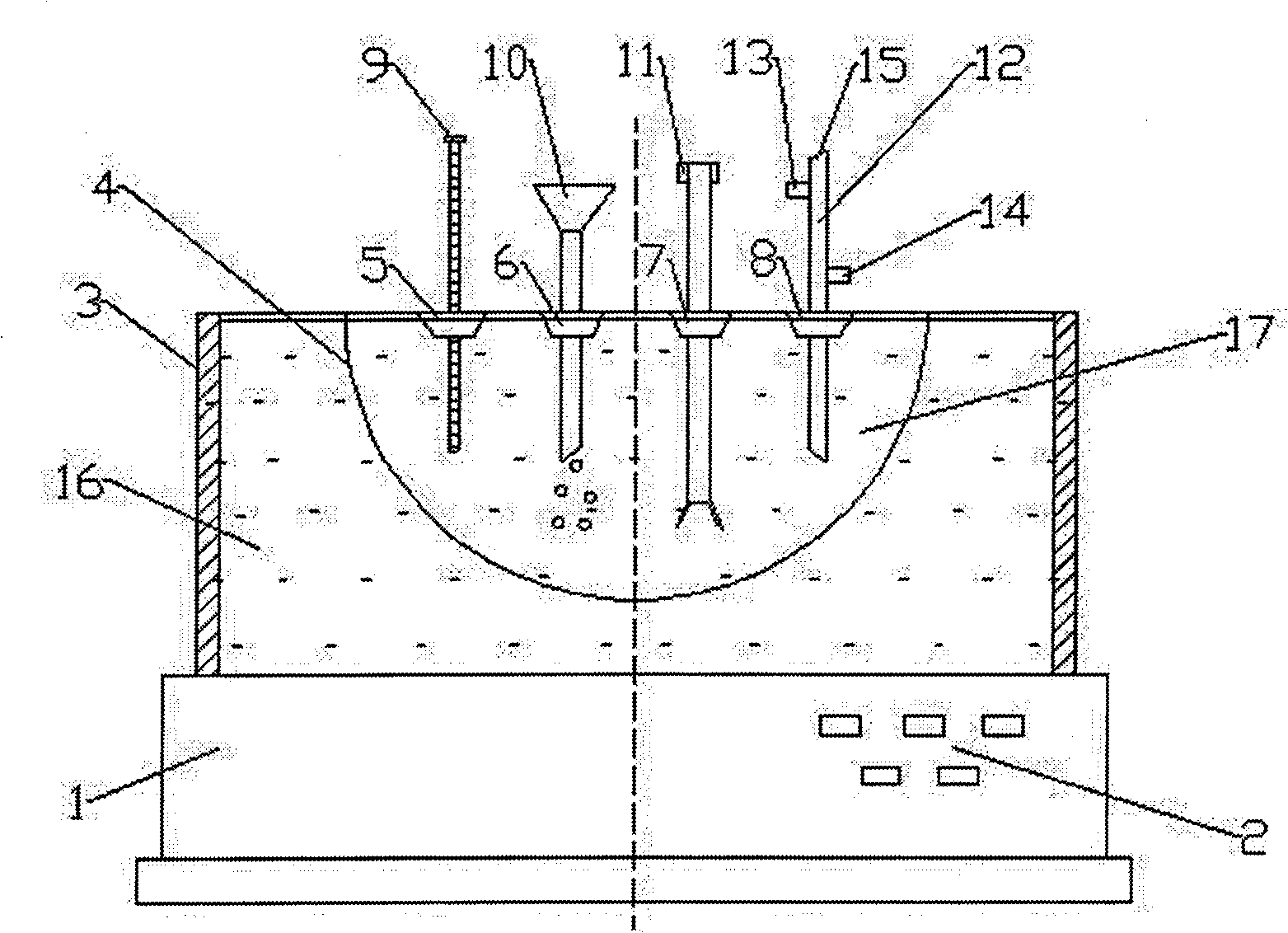

[0068] The present invention will be further described below in conjunction with accompanying drawing:

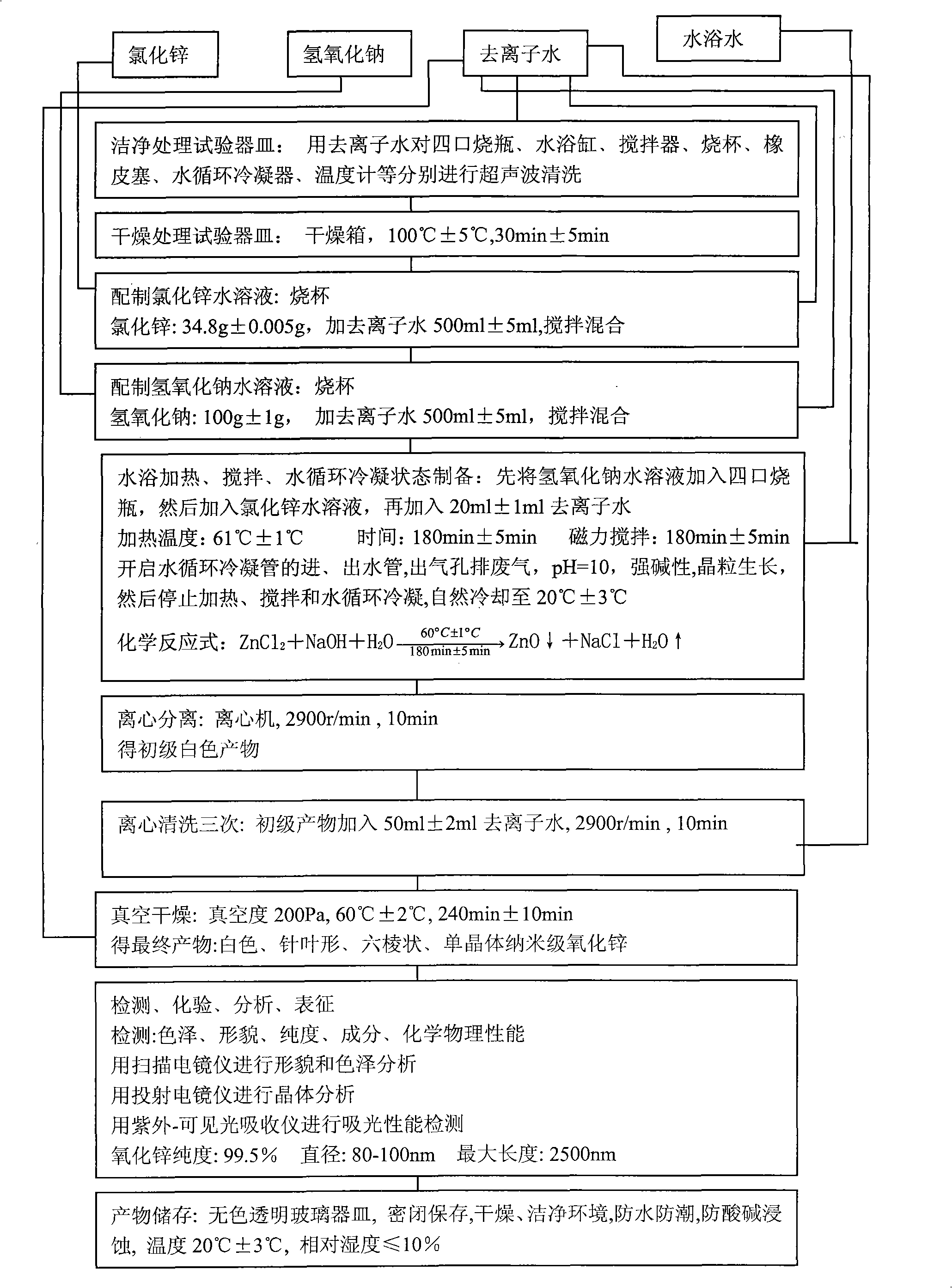

[0069] figure 1 As shown, for the preparation of the process flow chart, the operation must be strictly carried out in accordance with the process flow and carried out in sequence.

[0070] The amount of chemical substances required for preparation is determined according to a preset range, with grams and milliliters as the unit of measurement, and for industrial production, with kilograms and liters as the unit of measurement.

[0071] Prepare the required test utensils: four-necked flasks, water bathtubs, magnetic stirrers, beakers, containers, water circulation condensers, thermometers, etc., should be cleaned ultrasonically to keep them clean to prevent impurities from intervening and by-products.

[0072] Zinc chloride aqueous solution and sodium hydroxide aqueous solution should be prepared in advance, carried out strictly according to the quantity value, stirring an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com