Method for preparing AlxGa(1-x)N triplet alloy semiconductor film at normal temperature

A ternary alloy and semiconductor technology, applied in semiconductor/solid-state device manufacturing, chemical instruments and methods, crystal growth, etc., can solve problems such as substrate or pre-buried layer thermal damage, device performance degradation, thin film function degradation, etc., to achieve High degree of ionization, lower preparation temperature, and growth-promoting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

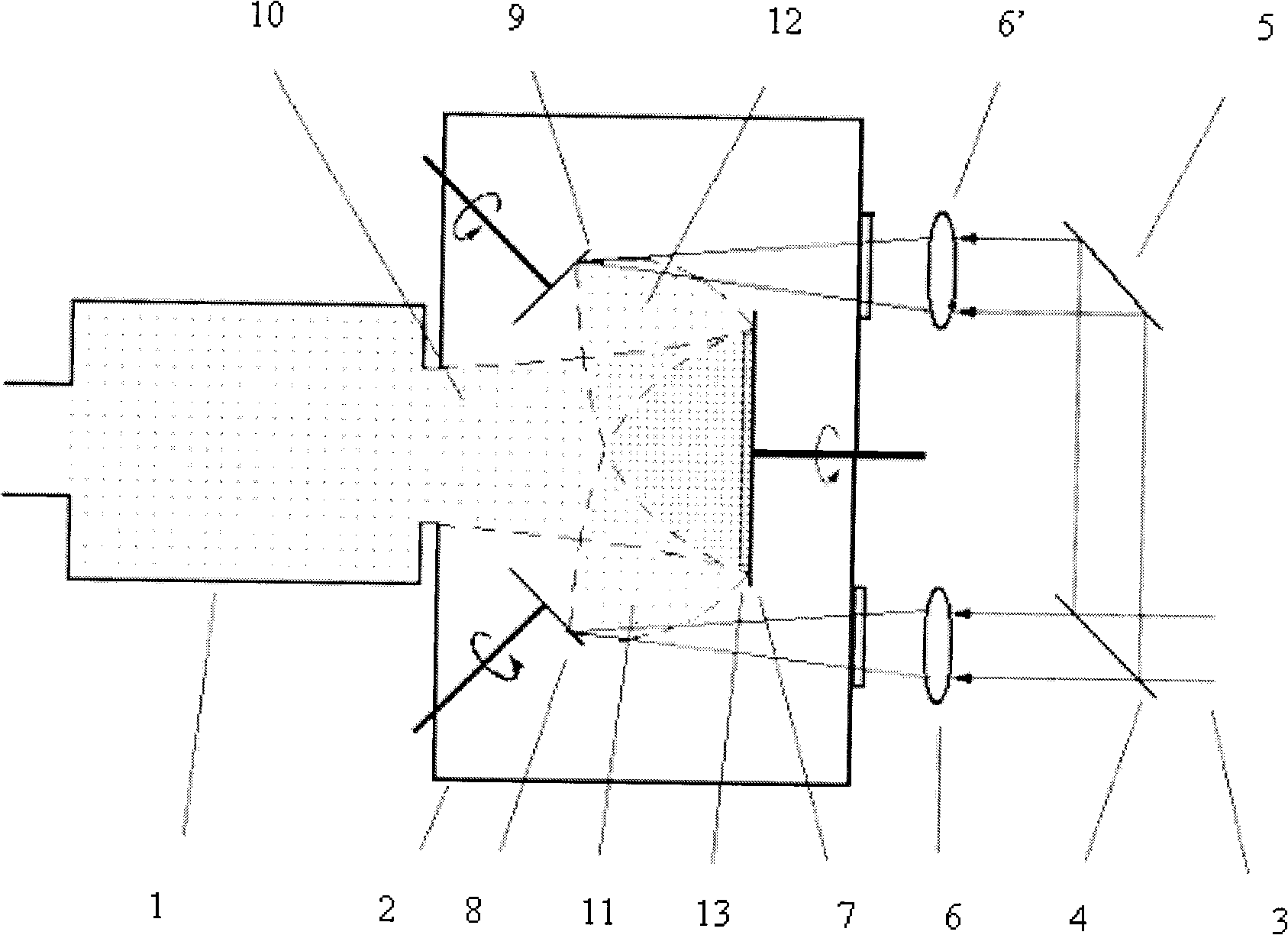

[0022] Embodiment 1: Al on Si substrate 0.5 Ga 0.5 Preparation of N(x=0.5) thin films

[0023] Al 0.5 Ga 0.5 The preparation device of N thin film is figure 1Configuration, 3 is Q-switched Nd:YAG laser output wavelength of 266, 355, 532 or 1064nm, repetition frequency of 1, 2, 5, 10 or 20Hz, pulse energy of 20-200mJ pulse laser beam, 8 is the purity of 99.995 % metal aluminum target, 9 is a polycrystalline AsGa target with a purity of 99.99%, 7 is a surface-polished and chemically cleaned single crystal Si (100) substrate, the aluminum target 8 and the AsGa target 9 are placed symmetrically with respect to the Si substrate 7 , the aluminum target 8, the AsGa target 9 and the Si substrate 7 are controlled by a motor outside the film forming chamber to rotate at a constant speed of tens of revolutions per minute. Vacuum the discharge chamber 1 and the film-forming chamber 2 to 10 -3 -10 -6 After Pa, fill the discharge chamber with high-purity nitrogen with a purity of 99....

Embodiment 2

[0024] Embodiment two: Al 2 o 3 Preparation of AlN(x=1) Thin Films on Substrates

[0025] AlN thin film preparation device according to figure 1 Configuration, 3 is Q-switched Nd:YAG laser output wavelength of 266, 355, 532 or 1064nm, repetition frequency of 1, 2, 5, 10 or 20Hz, pulse energy of 20-200mJ pulse laser beam, 8 is the purity of 99.995 % metallic aluminum target, no AsGa target, 7 for surface polished and cleaned single crystal Al 2 o 3 substrate, Al target 8 vs. Al 2 o 3 The position of the substrate 7 is the same as that of the aluminum target relative to the Si substrate in Example 1, and the aluminum target 8 and the Al target 2 o 3 The substrate 7 is controlled by a motor outside the film forming chamber to rotate at a constant speed of tens of revolutions per minute. Vacuum the discharge chamber 1 and the film-forming chamber 2 to 10 -3 -10 -6 After Pa, fill the discharge chamber with high-purity nitrogen with a purity of 99.999% to 10 -1 -10 -2 Pa...

Embodiment 3

[0026] Example three: SiO 2 Preparation of GaN(x=0) Thin Films on Substrates

[0027] GaN thin films were prepared by figure 1 Configuration, 3 is the Q-switched Nd:YAG laser output wavelength of 266, 355, 532 or 1064nm, repetition frequency of 1, 2, 5, 10 or 20Hz, pulse energy of 20-200mJ pulsed laser beam, 9 is the purity of 99.99 % polycrystalline AsGa target, no Al target, 7 for surface polished and cleaned SiO 2 substrate, AsGa target 9 versus SiO 2 The position of the substrate 7 is the same as that of the AsGa target relative to the Si substrate in Embodiment 1, and the AsGa target 9 and the SiO 2 The substrate 7 is controlled by a motor outside the film forming chamber to rotate at a constant speed of tens of revolutions per minute. Vacuum the discharge chamber 1 and the film-forming chamber 2 to 10 -3 -10 -6 After Pa, fill the discharge chamber with high-purity nitrogen with a purity of 99.999% to 10 -1 -10 -2 Pa is used as the working gas to keep the gas in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com