Biodegradable polymer containing phosphorylcholine and polyethylene glycol and synthetic method thereof

A polyethylene glycol, biodegradable technology, applied in the direction of transportation and packaging, packaging item types, special packaging items, etc., can solve the problem of reducing the adsorption capacity of protein molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 0.4g of MPC (the weight ratio of MPC is approximately the weight ratio of PC, the same below) and 0.6g of PEG-PLA with double bonds in chloroform, add a free radical polymerization initiator, and react at 60°C for 8 hours , the product was precipitated with methanol and dried in vacuo. PEG-PLA with a double bond is prepared by reacting PEG at one end with acryloyl chloride to initiate ring-opening polymerization of lactide. The reaction process is as follows:

[0025]

experiment example 1

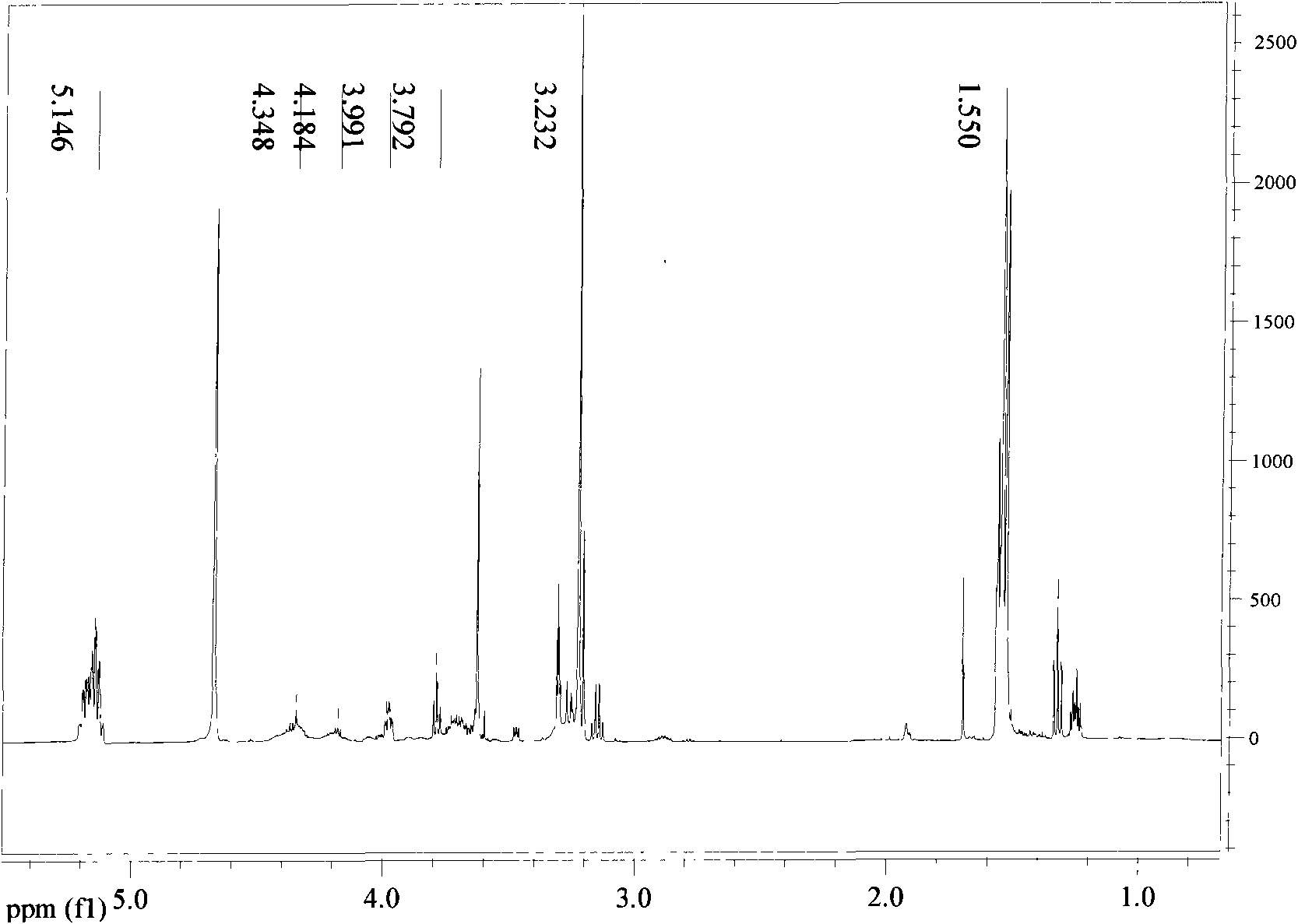

[0026] Determination of Experimental Example 1 Polymer Structure

[0027] Experimental instrument: NMR

[0028] Experimental method: take by weighing the experimental sample of embodiment 1, dissolve in deuterium reagent, make 1 H-NMR test. figure 1 For Example 1 polymer 1 H-NMR spectrum, its characteristic peak -N(CH 3 ) 3 ,-OCH 2 CH 2 OPOCH 2 -, -CH 2 N corresponds to 3.212, 3.985-4.363, 3.792 in the figure respectively, and δ=3.643 is in PEG-(CH 2 CH 2 O) 45 -中-CH 2 - the characteristic peak, A 3.630 / A 3.982 =2.67 / 1.13, it can be calculated that MPC:PEG-PLA=38:1 in the copolymer, that is, the copolymer contains 34.8% (wt%) MPC.

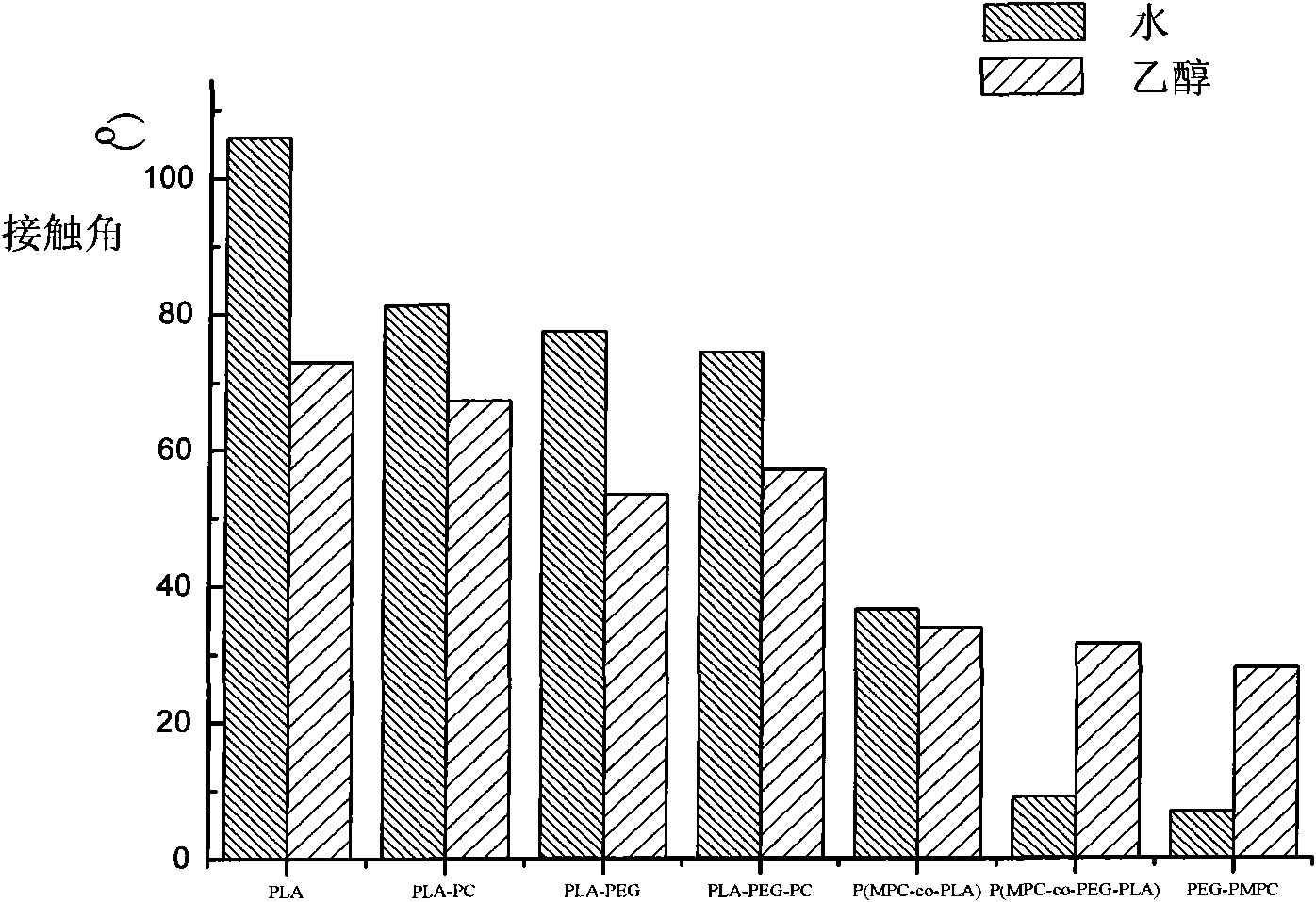

[0029] Experimental Example 2 Measurement of Static Contact Angle

[0030] Experimental reagents: deionized water, ethylene glycol, chloroform

[0031] Experimental Instrument: Contact Angle Meter

[0032] Experimental method: dissolve the polymer of Example 1 in chloroform, and coat a film on a glass slide. After the chloroform v...

experiment example 3

[0033] Experimental Example 3 Platelet Adsorption Test

[0034] Experimental reagents: absolute ethanol, platelet enrichment solution (PRP), PBS buffer, glutaraldehyde solution

[0035] Experimental instrument: SEM

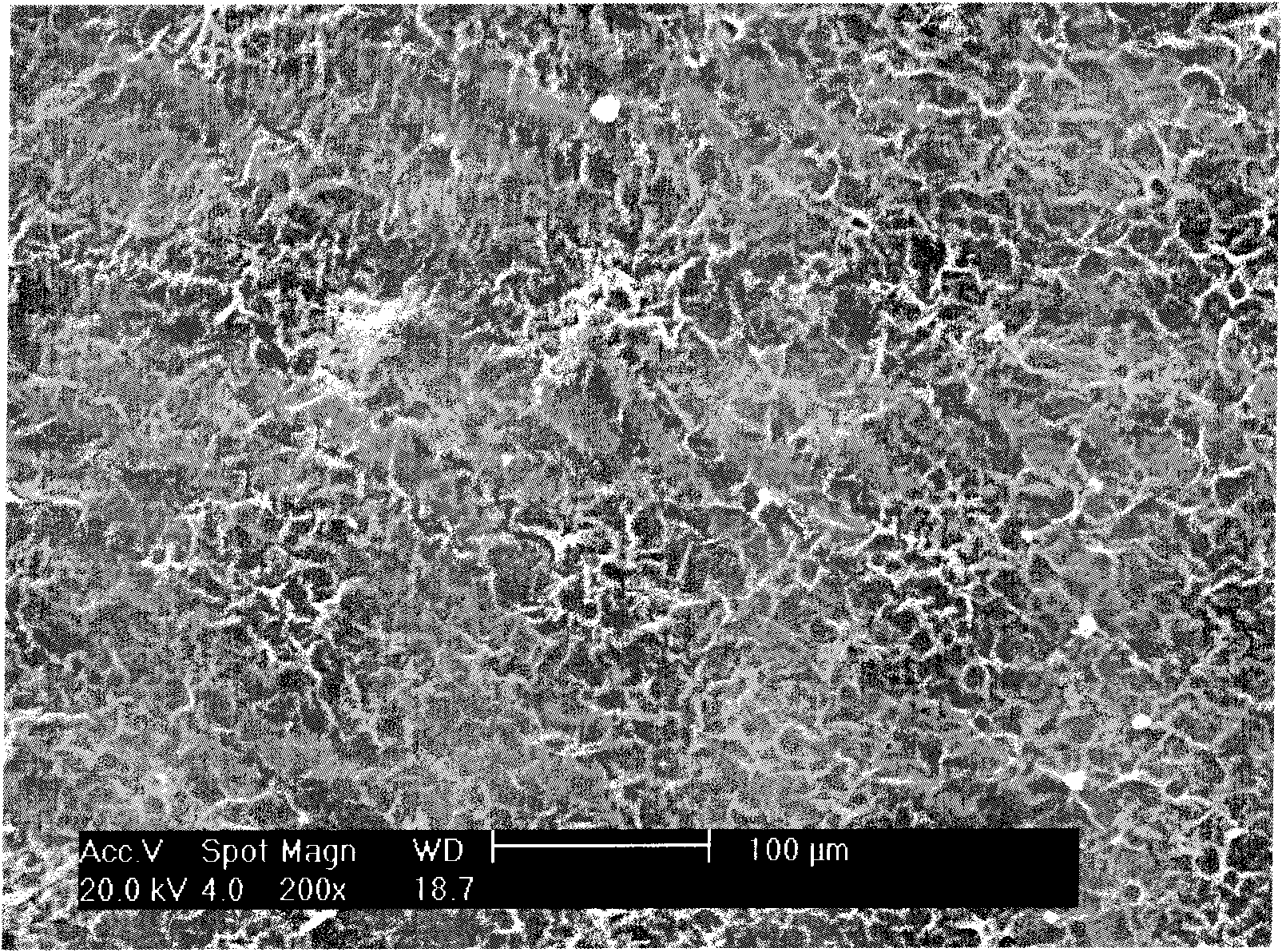

[0036] Experimental method: the coating film of Example 1 was immersed in PBS buffer solution, taken out after equilibrating at room temperature for 1 hour, and dried after taking out. Drop PRP on the sample to cover it, wash it with PBS solution for 3 times after 1 hour at 37 °C, then immerse the polymer film in glutaraldehyde solution for 1.5 hours, wash it with triple distilled water three times, and dehydrate it with anhydrous ethanol gradient. Observed by SEM after drying. image 3 Photograph of platelet adsorption. Although the surface of P(MPC-co-PEG-PLA) is not smooth, it can be seen that the number of platelets is very small, indicating that the combined effect of PEG and more PC groups has a significant effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com