Composite micro-nano structure array on high light-transmission substrate and method and application thereof

A technology of light-transmitting substrate and micro-nano structure, applied in the field of micro-nano structure and corresponding sensors, can solve the problems of lack of comprehensive research and utilization of properties, and achieve the effects of easy large-area preparation, simple process and simple structure, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

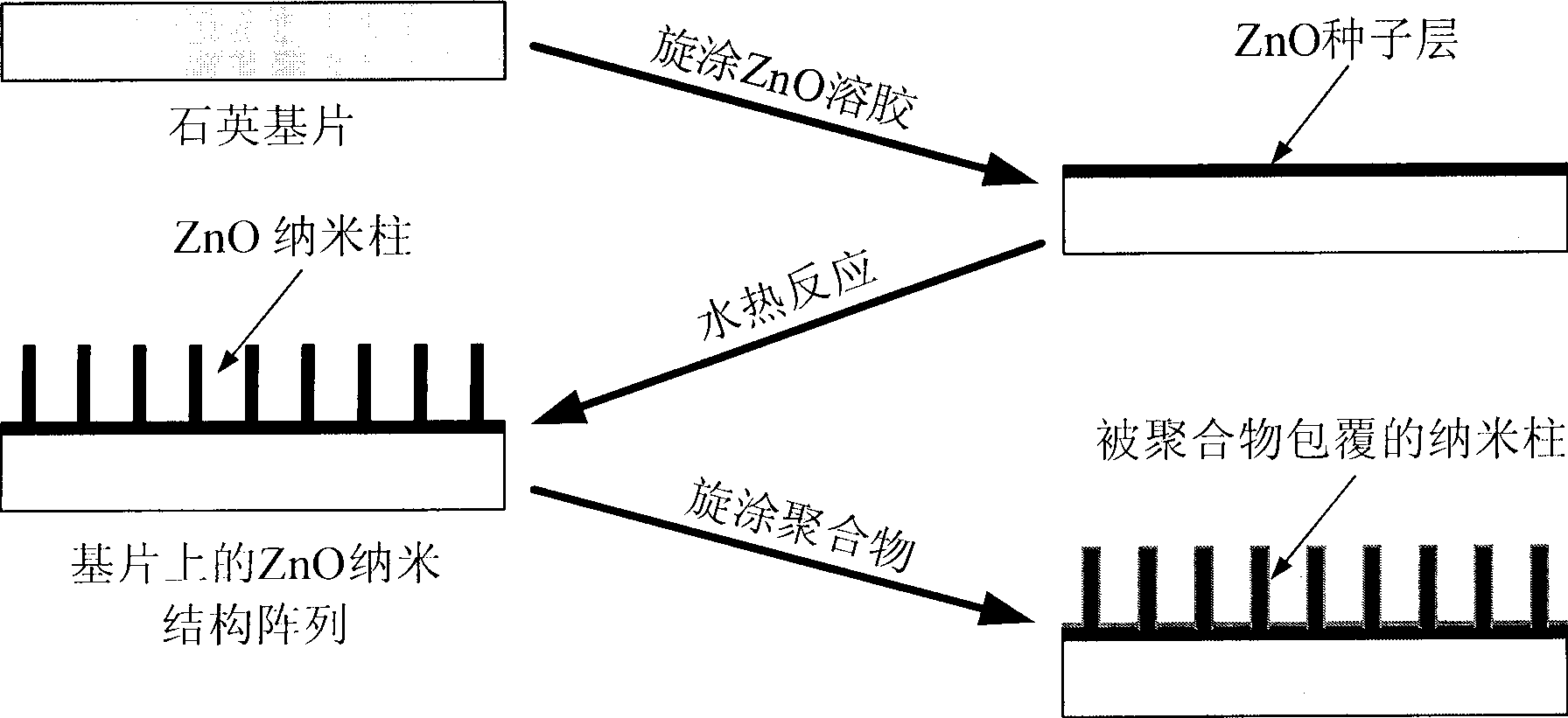

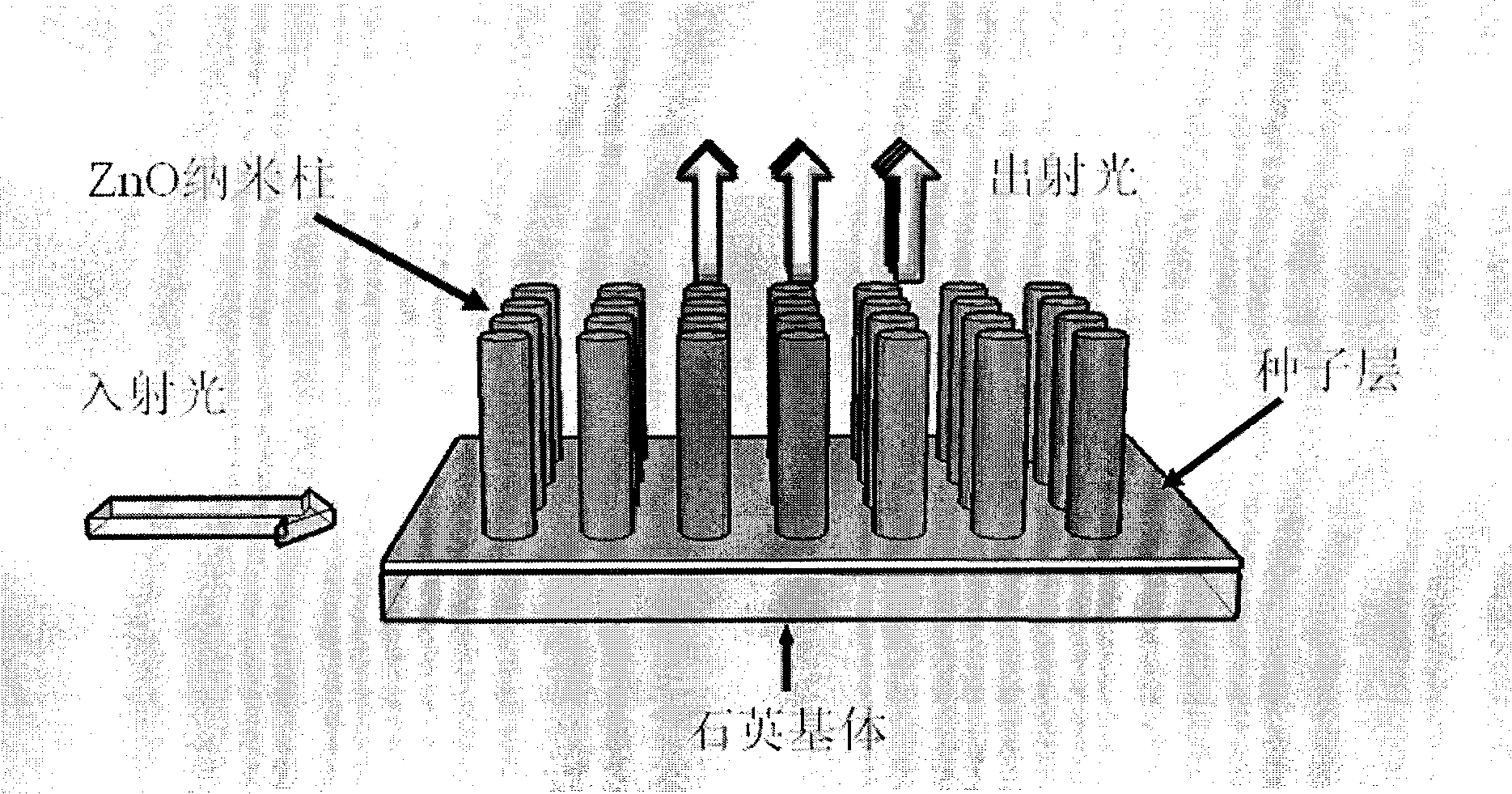

[0031] The preparation process of the ZnO nanocolumn array: 1. Pretreatment cleaning and hydrophilic treatment of the quartz substrate; 2. 3.29g Zn(Ac) 2 2H 2 O was dissolved in 30ml of ethylene glycol methyl ether, and 0.9ml of ethylenediamine was slowly added during stirring at 60°C, and a transparent colloid was obtained after 30 minutes; 3. Spin-coat the colloid on the pretreated Quartz substrate and post-baked at 400 ° C for 1 h; 4. Place the obtained substrate vertically in different concentrations of Zn(NO 3 ) 2 and (CH 2 ) 6 N 4 5. The substrate with zinc oxide nanocolumns obtained after hydrothermal growth was ultrasonically cleaned in high-purity water and ethanol, respectively, and then dried at 120°C for 1 hour. image 3 Shown is the same concentration of 0.01M Zn(NO 3 ) 2 and (CH 2 ) 6 N 4 The SEM image of the nano-column structure obtained by reacting in the mixed aqueous solution at 90°C for 6 hours shows that the distribution of the nano-columns is re...

Embodiment 2

[0033] Preparation process of zinc oxide mound structure array: Steps 1-3 are the same as in Example 1; 4. Prepare 0.02mol / L Zn(NO 3 ) 2 and 0.01mol / L (CH 2 ) 6 N 4 50ml of the mixed aqueous solution is formed, and 0.8ml of concentrated ammonia water with a concentration of 13mol / L is added; 5. The substrate prepared in 1-3 is vertically placed in the mixed solution, and reacted at 90°C for several hours; 6. Same as in Example 1 In step 5, an array of mound structures is obtained.

Embodiment 3

[0035] Preparation process of porous alumina array: 1. Dissolve 15g oxalic acid in 300ml ultrapure water to obtain oxalic acid solution, dissolve 10ml phosphoric acid in 220ml ultrapure water to obtain phosphoric acid pore-enlarging solution, dissolve 7.6ml phosphoric acid and 3.6g chromium trioxide Prepare a mixture of phosphoric acid and chromic acid in 400ml of ultra-pure water; 2. Immerse the polished high-purity aluminum sheet in the oxalic acid solution, and perform electrochemical corrosion for 1 hour in a water bath at 4°C, with a voltage of 50V and a current of 0.02~ 0.34A; 3. Immerse the corroded aluminum sheet in a mixture of chromic acid and phosphoric acid, and corrode it for 50 minutes at 50°C; 4. Then put the corroded aluminum sheet in an oxalic acid solution for 1 hour of electrochemical corrosion in a water bath at 4°C. The voltage is 50V, and the current is 0.02-0.20A; 5. The obtained substrate is immersed in a phosphoric acid pore-enlarging solution, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com