Electrochemical zinc-water hydrogen production and storage system and applications thereof

A technology of electrochemical and water hydrogen production, applied in the direction of electrochemical generators, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of expensive high-power power devices, inability to provide hydrogenation and co-combustion of internal combustion engines, and reduce pollution. Achieve the effect of convenient combination, simple processing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

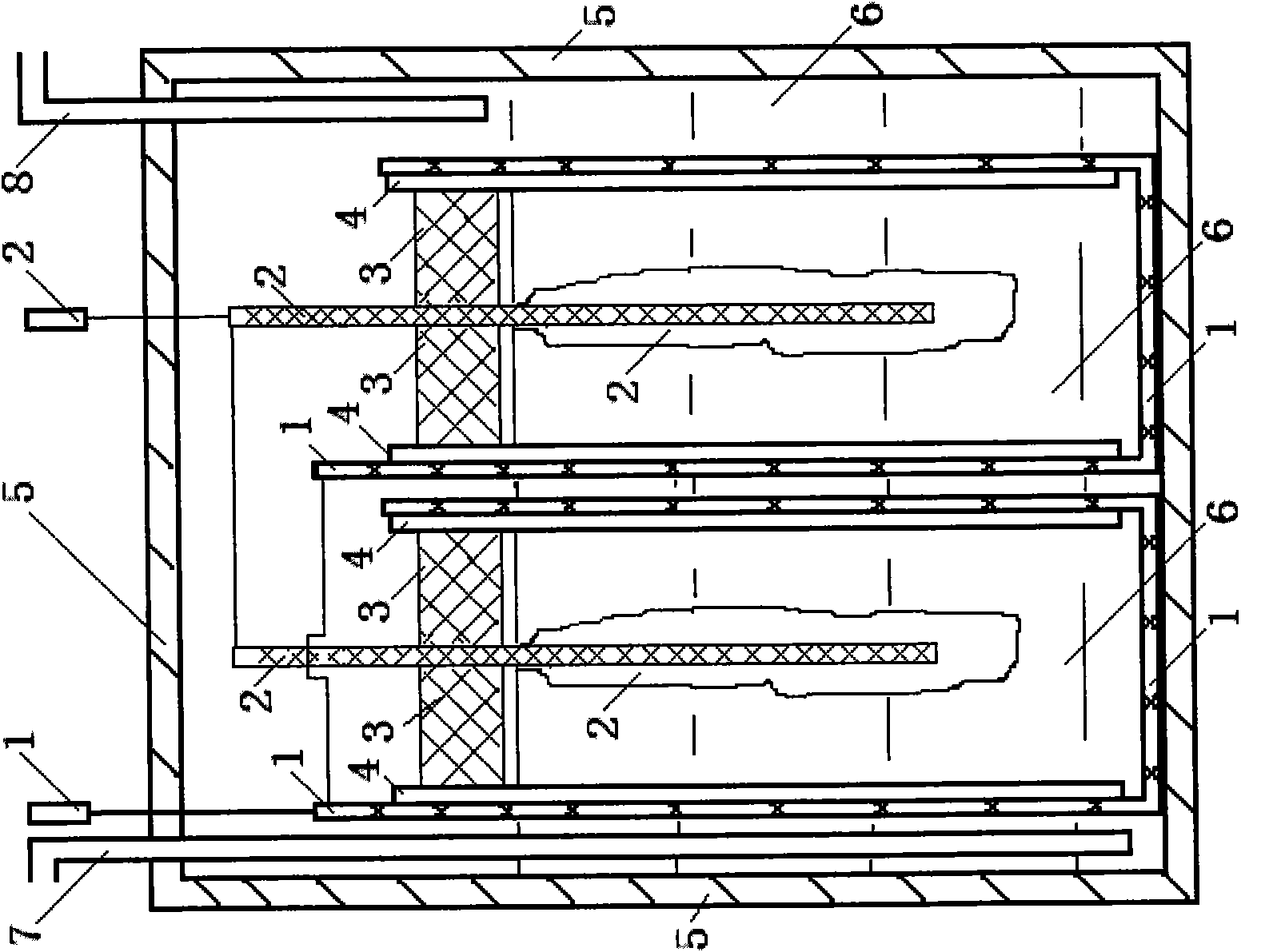

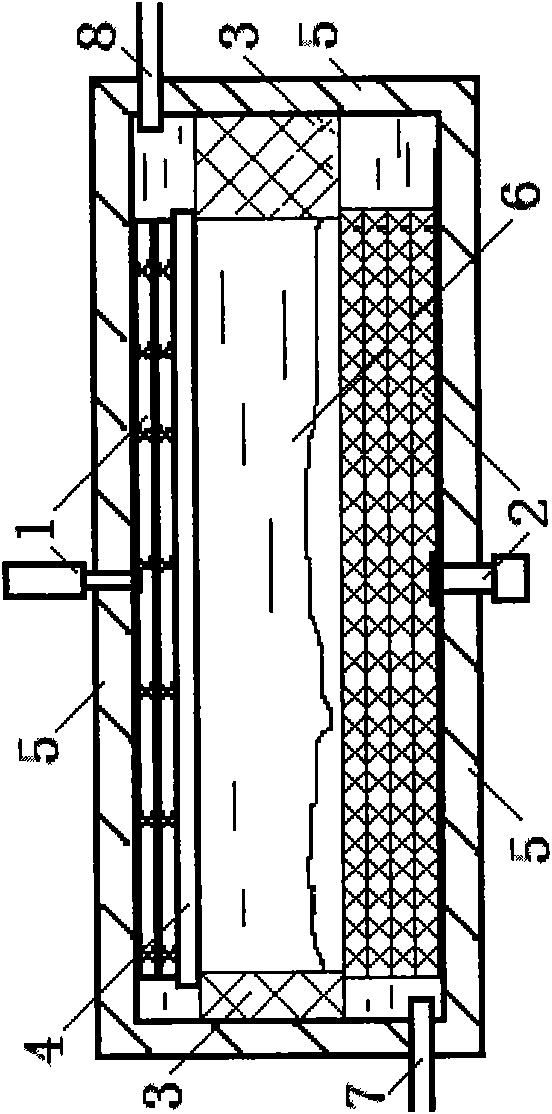

[0045] Example 1 A hydrogen production and hydrogen storage unit with electrodes placed vertically: 80-mesh tinned brass mesh is used as the current collector for the zinc electrode 2, and 10-mesh polyethylene mesh is used as the separator 3, with a space of 2 mm wide separated by polyethylene grafting. Membrane is diaphragm 4, and electrolytic solution 6 is the aqueous solution (mass concentration) that contains 4% zinc oxide, 33% potassium hydroxide, and gas-evolving electrode area is 16cm 2 , electrolyte intermittent circulation.

[0046] Test 1: Charging with a constant current of 0.8 amps, charging time 5-6 minutes, voltage 2.1-2.5 volts; without external voltage, only the gas-evolving electrode and the zinc electrode are discharged in the external circuit to produce hydrogen through the 20-amp current range of the multimeter, and discharge for 30 minutes Finish. Such charging and discharging cycles are repeated ten times.

[0047] Test 2: Charging with a constant curre...

example 2

[0048] Example 2 A hydrogen production and hydrogen storage unit with electrodes placed horizontally: gas evolution electrode 1 uses two layers of foamed nickel sheets, and the effective area of gas evolution electrode 1 is 15cm 2 , 80-mesh tinned brass mesh is the current collector of zinc electrode 2, 10-mesh polyethylene mesh is used for partition 3, and 6 layers are set up to separate a space of 6mm width. Diaphragm 4 is not installed, and electrolyte 6 contains 4% zinc oxide , 33% potassium hydroxide aqueous solution (mass concentration), the electrolyte solution is continuously circulated.

[0049] Charge with a constant current of 0.5 amps, the charging time is 2 hours, and the voltage is 2.1-2.5 volts. Do not drag the discharge, only discharge the gas-evolving electrode and the zinc electrode through the current gear of the multimeter to produce hydrogen until the voltage is less than 1 millivolt, and charge and discharge so repeatedly for ten times.

example 3

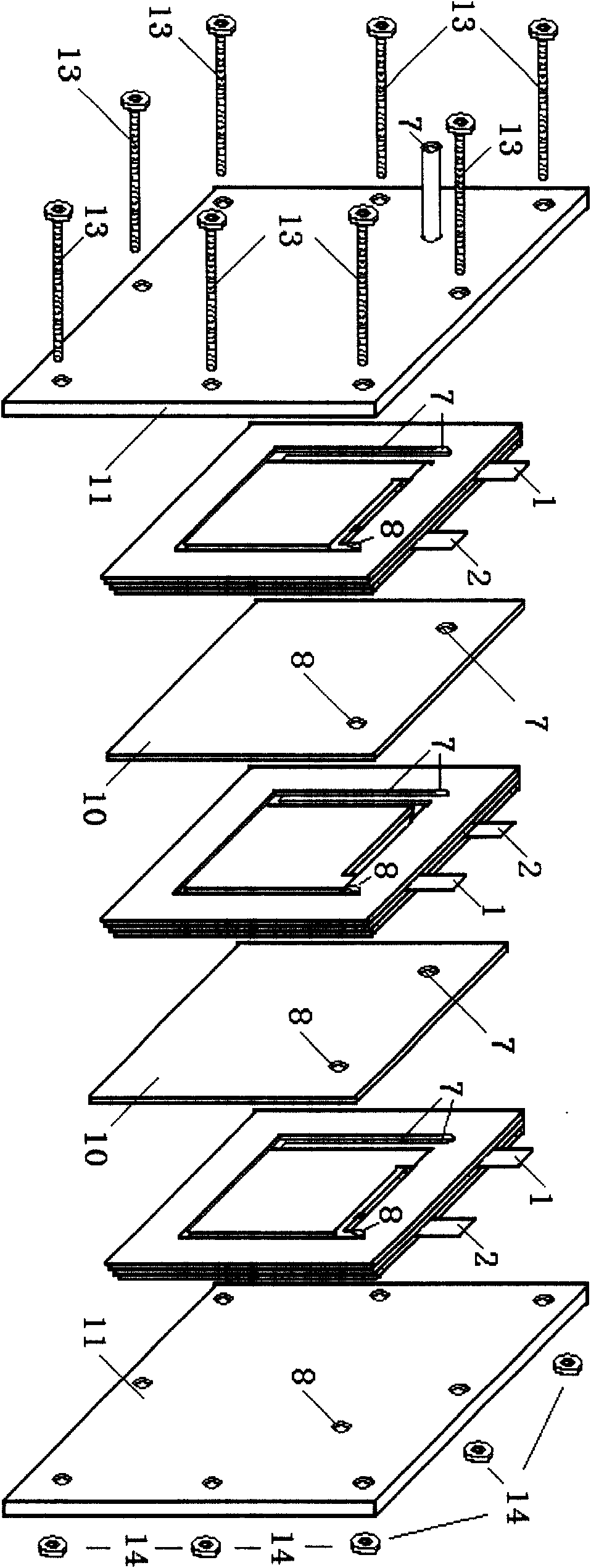

[0050] Example 3 45 hydrogen production and hydrogen storage units with electrodes placed vertically: 0.1 mm thick copper sheet is used as the current collector of zinc electrode 2, 3 mm thick rubber is cut into M shape as spacer 12, and polytetrafluoroethylene with a hole diameter of 1.5 cm The net is a partition net 3, which separates a 4mm wide space without a diaphragm 4. The aqueous solution containing saturated zinc oxide, 40% potassium hydroxide, and 1.5% lithium hydroxide (mass concentration) is the electrolyte solution 6, and the area of the gas-evolving electrode is 60 cm per unit 2 . The hydrogen production current can reach 1.5 to 4.0 amps. 9 hydrogen production and storage unit circuits are connected in series, using 8 partitions 10 and 2 end plates 11, assembled into one group by means of filter press, 5 groups of circuits and fluid passages are connected in series respectively, the total area of gas evolution electrodes in this system is 2700 square meters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com