Method for preparing niobium pentaoxide membrane

A niobium pentoxide and thin film technology, applied in the field of thin film preparation, can solve the problems of high equipment requirements, complex process, unstable niobium alkoxide and inorganic salt, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

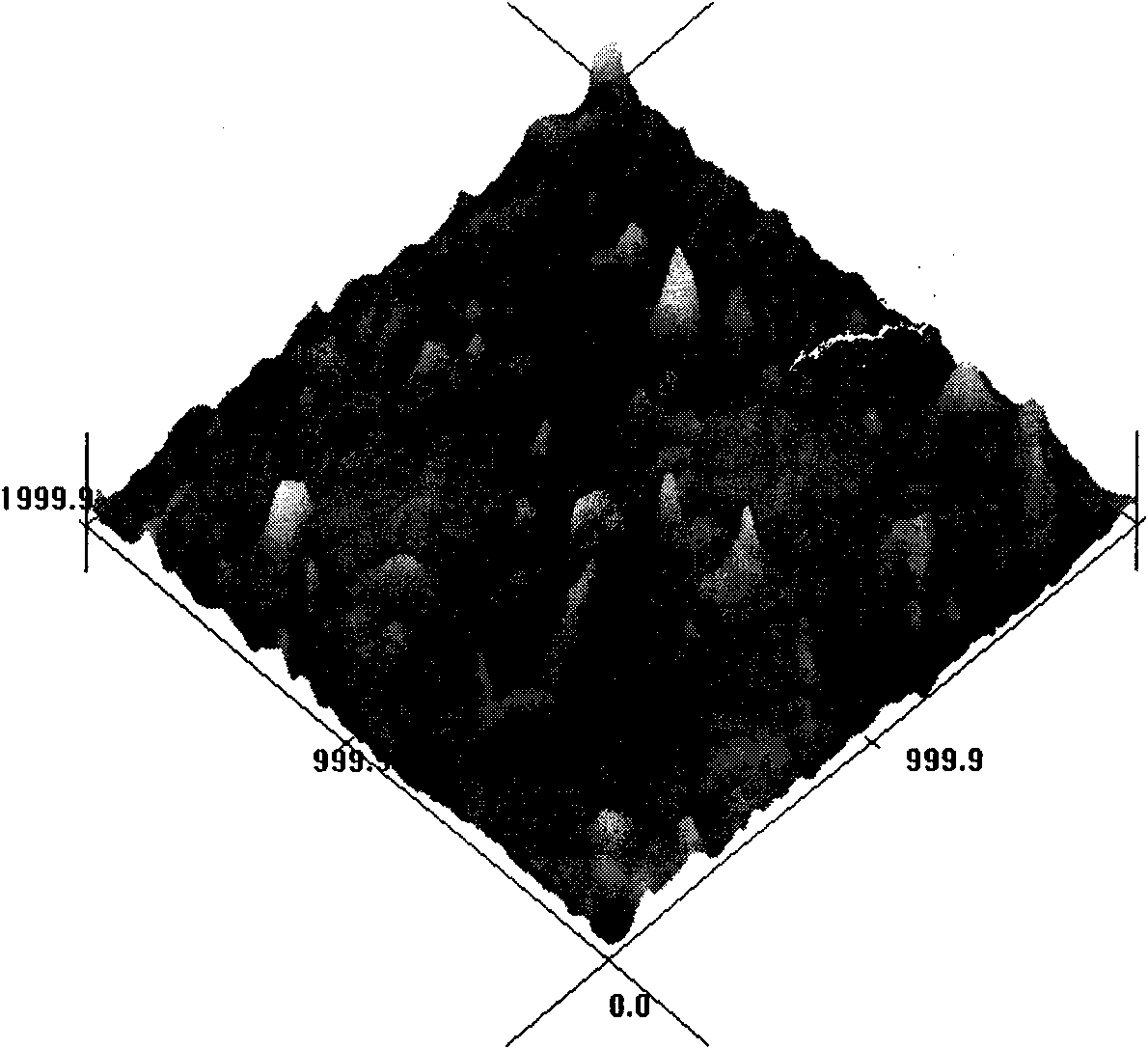

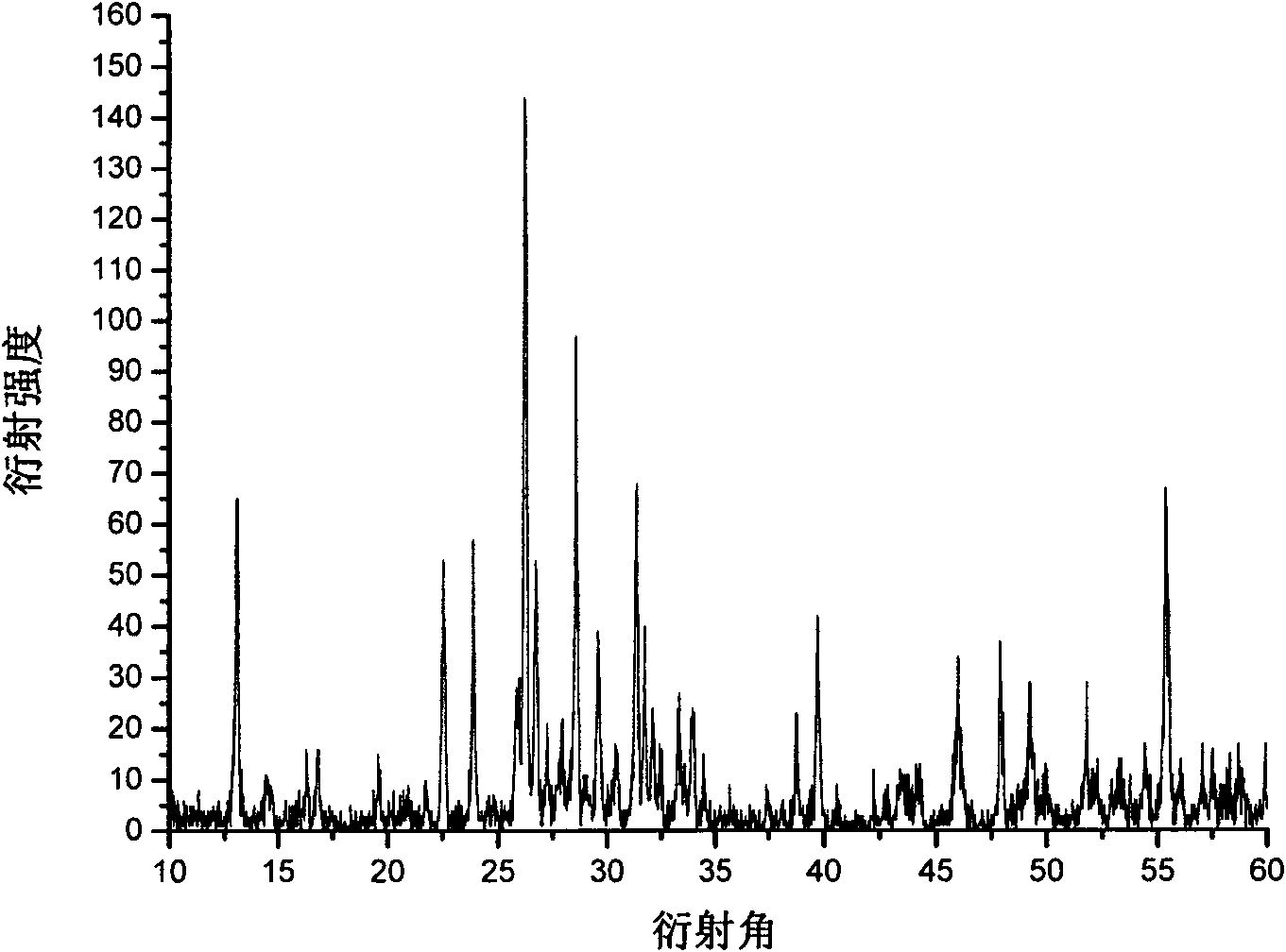

Image

Examples

Embodiment 1

[0027] a, take niobium pentoxide 39.8721g and potassium carbonate 6.9105g respectively, put into agate mortar and fully grind evenly;

[0028] b. Put the ground mixture in a muffle furnace to react at 600° C. for 6 hours.

[0029] c. Take out 1 g of calcined material, add 1 L of 1 mol / L hydrochloric acid and stir for 24 hours, after filtering, add hydrochloric acid in the same proportion, stir for the same time and filter, repeat 4 times.

[0030] d. The filter cake filtered in step c is fully washed with deionized water, and put into an oven at 60° C. for 6 hours.

[0031] e. Take out 1 g of the dried powder and add it to 100 ml of 0.5 mol / l tetra-n-butylammonium hydroxide solution, stir for 72 hours, and then centrifuge for 10 minutes in a high-speed centrifuge at 10,000 r / min to obtain niobium pentoxide nanosheet sol.

[0032] f. Take a 30×10×1.5mm quartz plate, wash it ultrasonically with detergent, acetone and deionized water in sequence, and dry it with pure nitrogen fo...

Embodiment 2

[0035] a. Weigh 79.7442 g of niobium pentoxide and 13.8210 g of potassium carbonate, respectively, put them into an agate mortar and grind them evenly.

[0036] b. Put the ground mixture in a muffle furnace to react at 800° C. for 12 hours.

[0037] c. Take out 1 g of calcined material, add 1 L of 1 mol / L hydrochloric acid and stir for 24 hours, after filtering, add hydrochloric acid in the same proportion, stir for the same time and filter, repeat 4 times.

[0038] d. The filter cake filtered in step c is fully washed with deionized water, and put into an oven at 80° C. for 8 hours.

[0039] e. Take out 1 g of the dried powder and add it to 100 ml of 0.5 mol / l tetra-n-butylammonium hydroxide solution, stir for 72 hours, and then centrifuge for 15 minutes under a high-speed centrifuge at 10,000 r / min to obtain niobium pentoxide nanosheet sol.

[0040] f. Take a 30×10×1.5mm quartz plate, wash it ultrasonically with detergent, acetone and deionized water in sequence, and dry it...

Embodiment 3

[0043] a. Weigh 79.7442 g of niobium pentoxide and 13.8210 g of potassium carbonate, respectively, put them into an agate mortar and grind them evenly.

[0044] b. Put the ground mixture in a muffle furnace to react at 1000° C. for 8 hours.

[0045] c. Take out 1 g of the calcined material, add 1L of 1mol / L hydrochloric acid and stir for 12 hours, after filtering, add hydrochloric acid in the same proportion, stir for the same time and filter, repeat 4 times.

[0046] d. The filter cake filtered in step c is fully washed with deionized water, and put into an oven at 100° C. for 12 hours.

[0047] e. Take out 1 g of the dried powder and add it to 100 ml of 0.5 mol / l tetra-n-butylammonium hydroxide solution, stir for 72 hours, and then centrifuge for 20 minutes in a high-speed centrifuge at 10,000 r / min to obtain niobium pentoxide nanosheet sol.

[0048] f. Take a 30×10×1.5mm quartz plate and clean it ultrasonically with detergent, acetone and deionized water in sequence, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com