A polymer gel hybrid solar cell

A technology of solar cells and polymers, applied in circuits, capacitors, photovoltaic power generation, etc., can solve the problems of limiting the properties of components and polymerization technology, and the inability of monomers to be polymerized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In one example, polyethylene oxide [PEO, Mw 400.000] is used for lithium iodide / iodine [LiI / I 2 ] and an inert lithium salt filled ethylene carbonate [EC] / propylene carbonate [PC] mixture. In the PEO polymer gel electrolyte, the solid polymer matrix of PEO provides dimensional stability for the electrolyte, while the high dielectric constants of the solvents PC and EC enable thorough dissociation of the Li salt. The low viscosity of PC and EC provides an ionic environment that favors high ion mobility. This type of polymer gel electrolyte has high ionic conductivity, more than 10 3 S / cm.

Embodiment 2

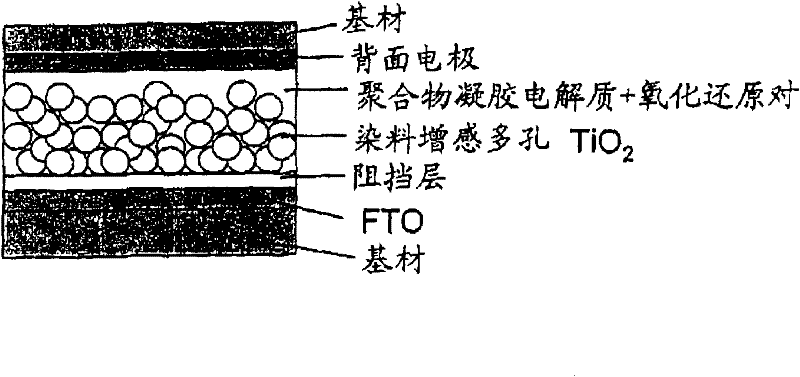

[0058] Solar cell preparation

[0059] barrier layer

[0060] Preparation by spray pyrolysis: an aerosol dispersion (0.2 M concentration) of the organic precursor titanium acetylacetonate (TAA, Aldrich) in ethanol was sprayed onto a structured FTO-coated glass substrate (in at 450°C) (Geomatic). In order to obtain thin, amorphous, dense TiO 2 layer (approximately 30 nm), the film was tempered at 500 °C for 1 hour in air.

[0061] Nanocrystalline TiO 2 Electrode + dye layer

[0062] Porous TiO 2 layer through the barrier TiO 2 The layer is screen-printed containing TiO with a diameter of 10nm or 20nm, respectively 2 Granules (Solaronix Company) (thickness depends on the mesh size of the sieve). In order to remove organic solvents and surfactants, and make TiO 2 Particles can contact each other, the porous TiO 2 The layers are heated in a first step until 85°C for 30 minutes and then sintered at 450°C for 1 / 2 hour. After cooling to 80°C, the film was placed in an etha...

Embodiment 3

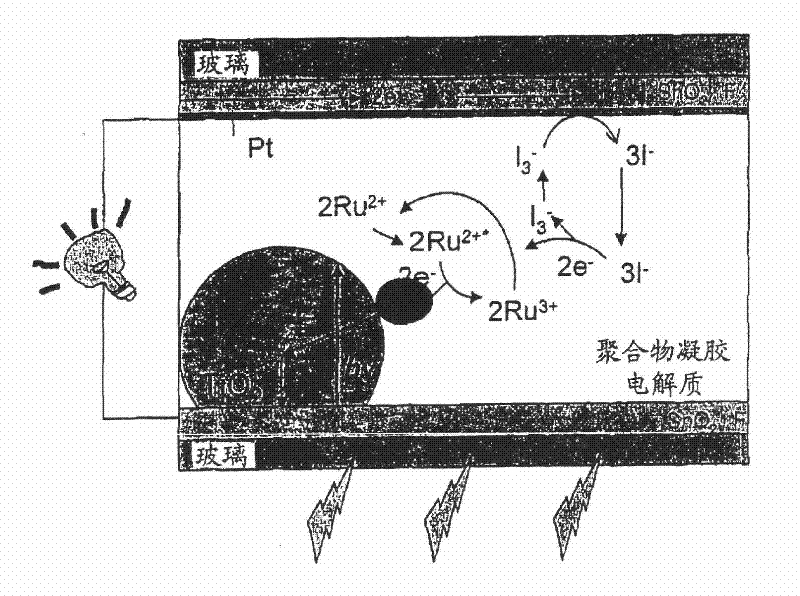

[0075] Photovoltaic cells by dye-sensitized porous TiO 2 A prefabricated gel electrolyte is drop-cast on top of the coated electrodes, and a platinum back electrode is inserted in between.

[0076] Nanocrystalline TiO 2 The thickness of the layer varies from 2 to 20 micrometers and contains particles with diameters of 10 or 20 nanometers. The illuminated area of the battery is about 0.5-0.6cm 2 . As a sensitizer dye, cis-di(thiocyanato)bis(2,2'-dipyridyl-4,4'-dicarboxylate) ruthenium(II) tetrabutylammonium (Ru(bpy) TBA).

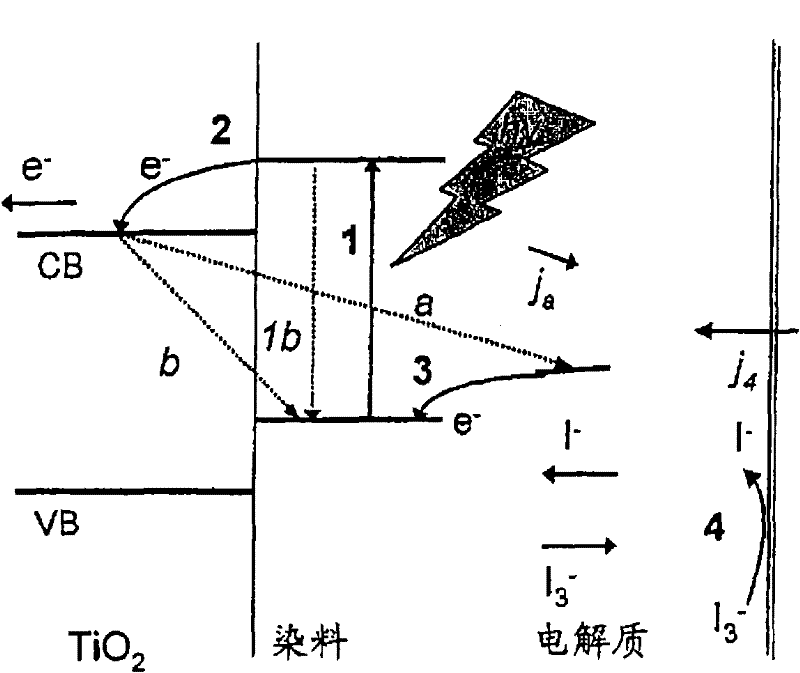

[0077] The electron migration and transport process in the battery is shown diagrammatically in figure 2 middle. The light absorbed by the dye molecules injects electrons into TiO 2 (t-10 -12 s) and inject holes into Li / I 2 system (t-10 -8 s). At the platinum back electrode, the formed I 3 - The substance will be reduced to I - , perform the following redox reaction [D. Kuciauskas, M.S. Freund, H.B. Gray, J.R. Winkler, and N.S. Lewis, J.Phys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionic conductivity | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

| power conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com