Modified catalyst for low-temperature fuel cell and preparation method thereof

A fuel cell and catalyst technology, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. The effect of reducing the amount, avoiding agglomeration, and improving the catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Preparation of Pt-PdNi / C (Pt2%) catalyst

[0030] Toner pretreatment: Vulcan XC-72 (Carbot Corp. BET: 237m 2 / g, abbreviated as C) Carbon powder is used as a catalyst carrier. It is pretreated before use. Firstly, it is washed with acetone 3 to 5 times to remove organic impurities, and then 2mol·L is used under stirring. -1 Nitric acid (HNO 3 ) And 30% hydrogen peroxide (H 2 O 2) Oxidize for 2 hours, and then wash with deionized water three times until the pH of the filtrate is greater than 5. The obtained powder was dried at 90°C for about 12 hours and placed in a desiccator for later use.

[0031] Preparation of PdNi sol: Weigh 62.5 mg of palladium chloride (PdCl 2 )Powder, put it into a 250mL round bottom flask, add 0.25mL concentrated hydrochloric acid and sonicate to PdCl 2 completely dissolved. Add 25mL ethylene glycol (EG) and stir to obtain a yellow transparent liquid, then add 151.2mg NiCl 2 ·6H 2 O and 207.4mg sodium citrate, stir for 0.5-1 hour to make...

Embodiment 2

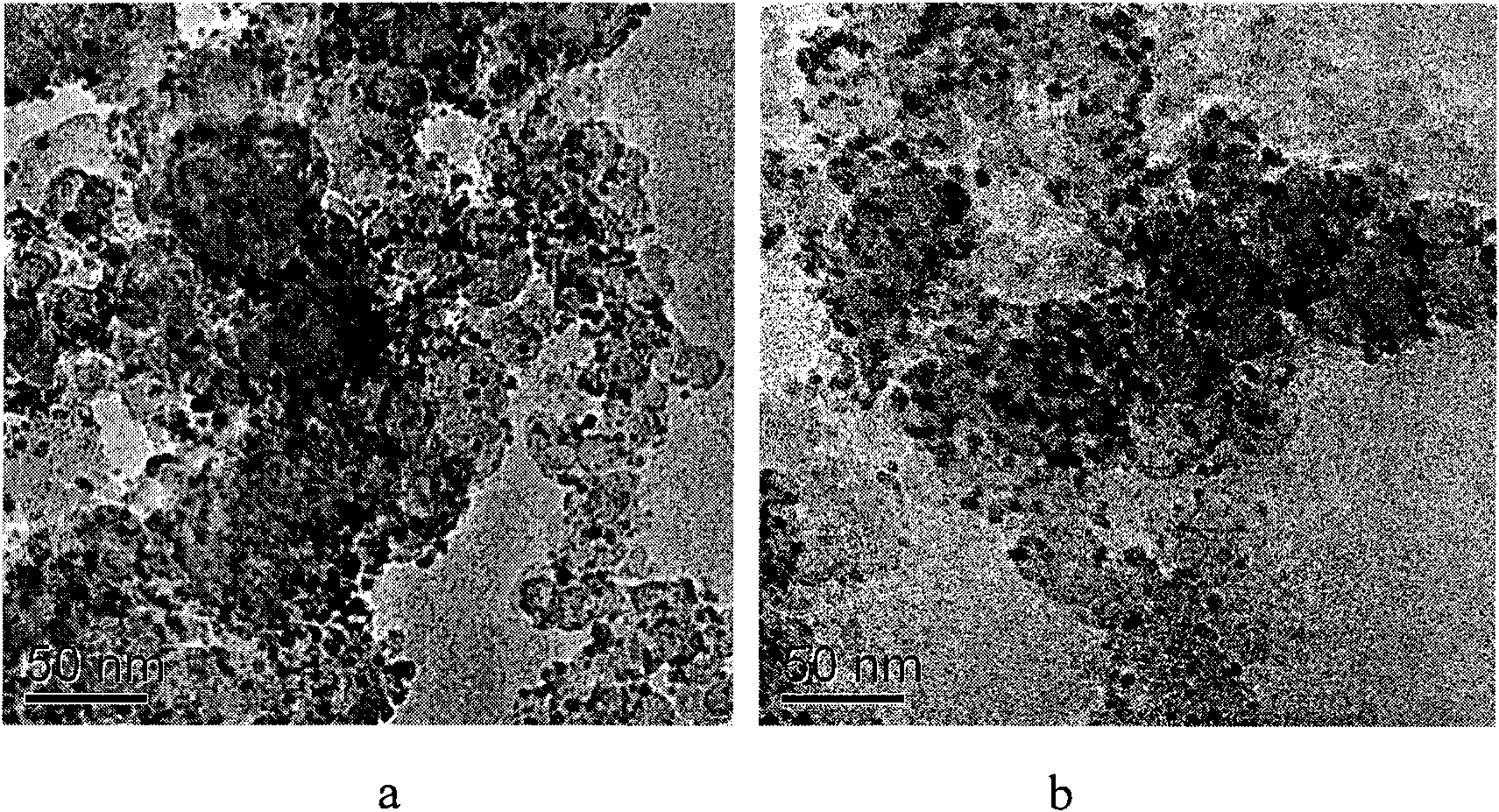

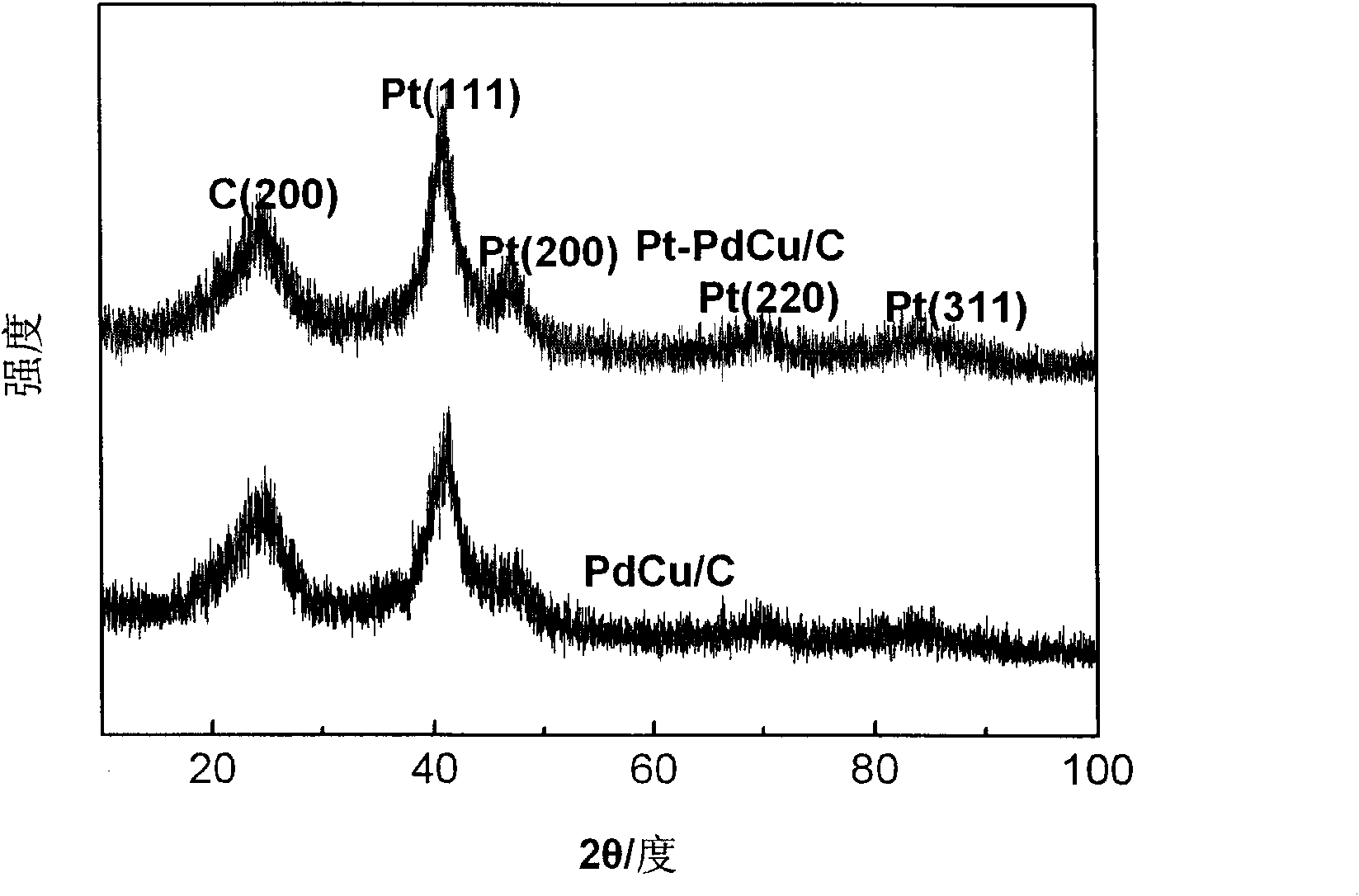

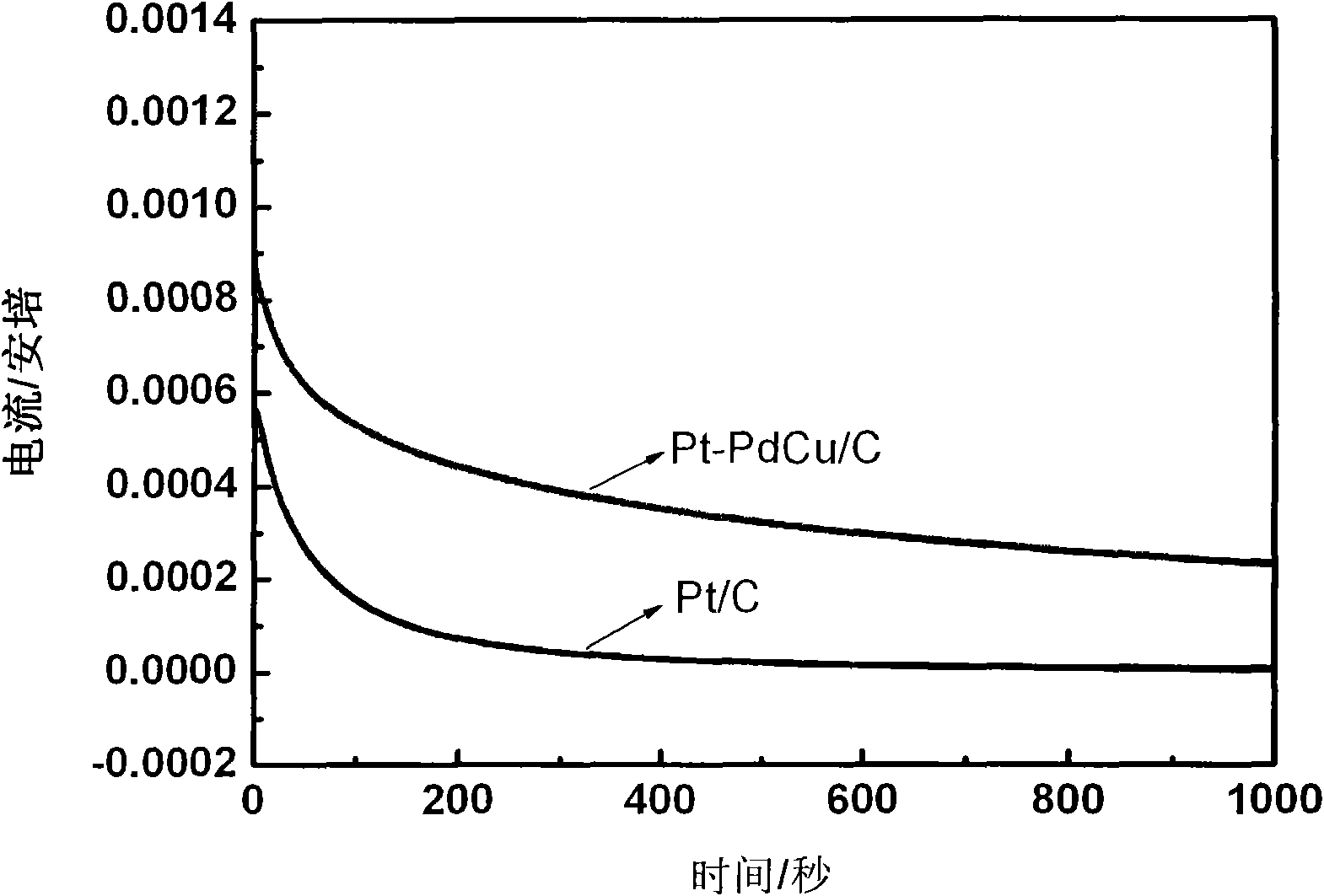

[0035] Example 2: Preparation of Pt-PdCu / C (Pt2%) catalyst

[0036] The pretreatment of carbon powder is the same as in Example 1.

[0037] Preparation of PdCu sol: Weigh 16.7mg of palladium chloride (PdCl 2 ), put it into a 250 mL single-neck round bottom flask, add 0.25 mL hydrochloric acid dropwise, and ultrasonically make it completely dissolved. Add 20ml ethylene glycol, 148mg sodium citrate and 26.9mg CuCl 2 ·2H 2 O, stir to completely dissolve; adjust the pH value to pH ≥9 with 5% potassium hydroxide in ethylene glycol solution (KOH / EG solution). After reacting at 160°C for 10 hours, a palladium-copper alloy sol is obtained.

[0038] The preparation of Pt-PdCu / C catalyst: the concentration of 20mg / ml H 2 PtCl 6 Add 0.16 ml of the aqueous solution to the palladium-copper alloy sol prepared in the previous step, and then add 80 mg of pretreated carbon powder, sonicate and stir for 20 minutes each, and react at 80° C. for 3 to 4 hours. Cool, let it stand overnight and then fil...

Embodiment 3

[0041] Example 3: Preparation of Pt-PdCo / C (Pt1%) catalyst

[0042] The pretreatment of carbon powder is the same as in Example 1.

[0043] Preparation of PdCo sol: Weigh 62.5mg of palladium chloride (PdCl 2 ), placed in a 250mL round-bottomed flask, add 0.25mL concentrated hydrochloric acid and ultrasound to PdCl 2 completely dissolved. Add 25mL ethylene glycol (EG) and stir to obtain a yellow transparent liquid; then add 224.5mg Co(NO 3 ) 2 ·6H 2 O and 207.4mg sodium citrate, stir for 0.5 hours to completely dissolve; then use 5% potassium hydroxide in ethylene glycol solution (KOH / EG solution) to adjust the pH to 9 and place it at 160°C under an electromagnetic stirrer Lower the reaction heat for 10 hours to obtain PdCo sol.

[0044] Preparation of Pt-PdCo / C catalyst: add 20mg / ml chloroplatinic acid (H 2 PtCl 6 ) 0.55ml of aqueous solution, 300 mg of pretreated carbon powder, added to the PdCo sol prepared above, ultrasound, stirring for 0.5 hours, reaction at 140 ℃ for 2 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com