Technique for separating and preparing rapeseed protein cogenerating rapeseed polyoses from the low-temperature cold pressing rapeseed dregs film

A technology of rapeseed protein and process method, which is applied in the field of low-temperature cold-pressed rapeseed meal membrane separation to prepare rapeseed protein for co-production of rapeseed polysaccharides, can solve the problems of rapeseed protein and rapeseed polysaccharides polluting the environment, and achieve good results Environmental friendliness, high purity and extraction rate, effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

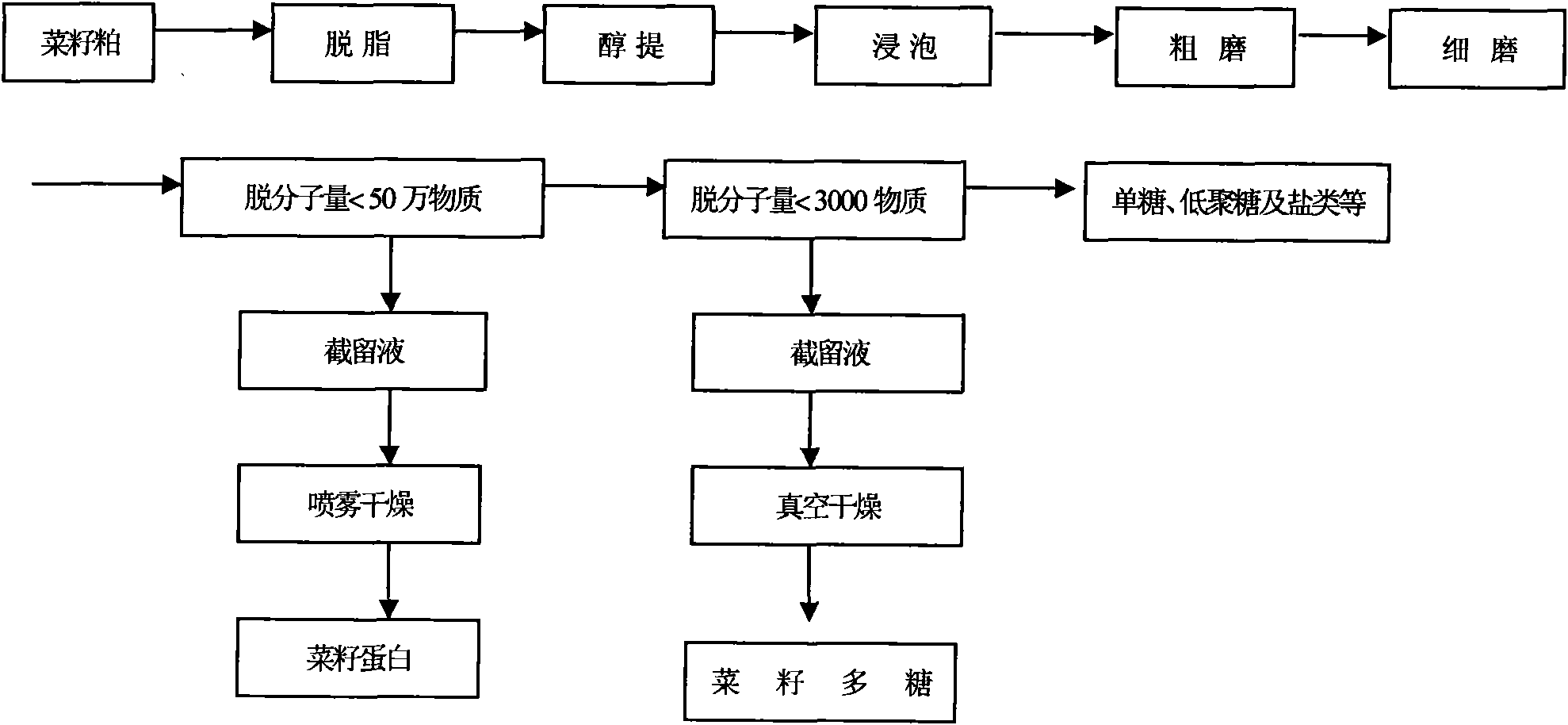

[0024] see figure 1 The method for preparing rapeseed protein co-production rapeseed polysaccharide by membrane separation of low-temperature cold-pressed rapeseed meal comprises the following steps:

[0025] (1) Rapeseed impurity removal: separate and remove dust, sand, straw and other impurities;

[0026] (2) Cold-pressed rapeseed: press the rapeseed with a cold residue machine at a temperature lower than 100°C, and separate most of the oil to obtain coarse meal;

[0027] (3) degreasing of crude meal: leaching out the oil remaining in the crude meal with organic solvent n-hexane until the oil content in the crude meal is less than 0.5%, to obtain defatted rapeseed meal;

[0028] (4) Alcohol extraction: Add 95% ethanol to the defatted rapeseed meal in a ratio of 1:5 mass / volume (m / v), soak at 20-50°C for 3 hours, repeat the operation twice, and then vacuum dry to recover ethanol , to obtain alcohol-extracted rapeseed meal;

[0029] (5) Soaking: Alcohol-extracted rapeseed m...

Embodiment 2

[0036] The cut-off molecular weight of the ultrafiltration membrane used in the ultrafiltration device for separating rapeseed protein is 450kDa.

[0037] The ultrafiltration membrane used in the ultrafiltration device for separating rapeseed polysaccharides has a cut-off molecular weight of 3 kDa.

[0038] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com