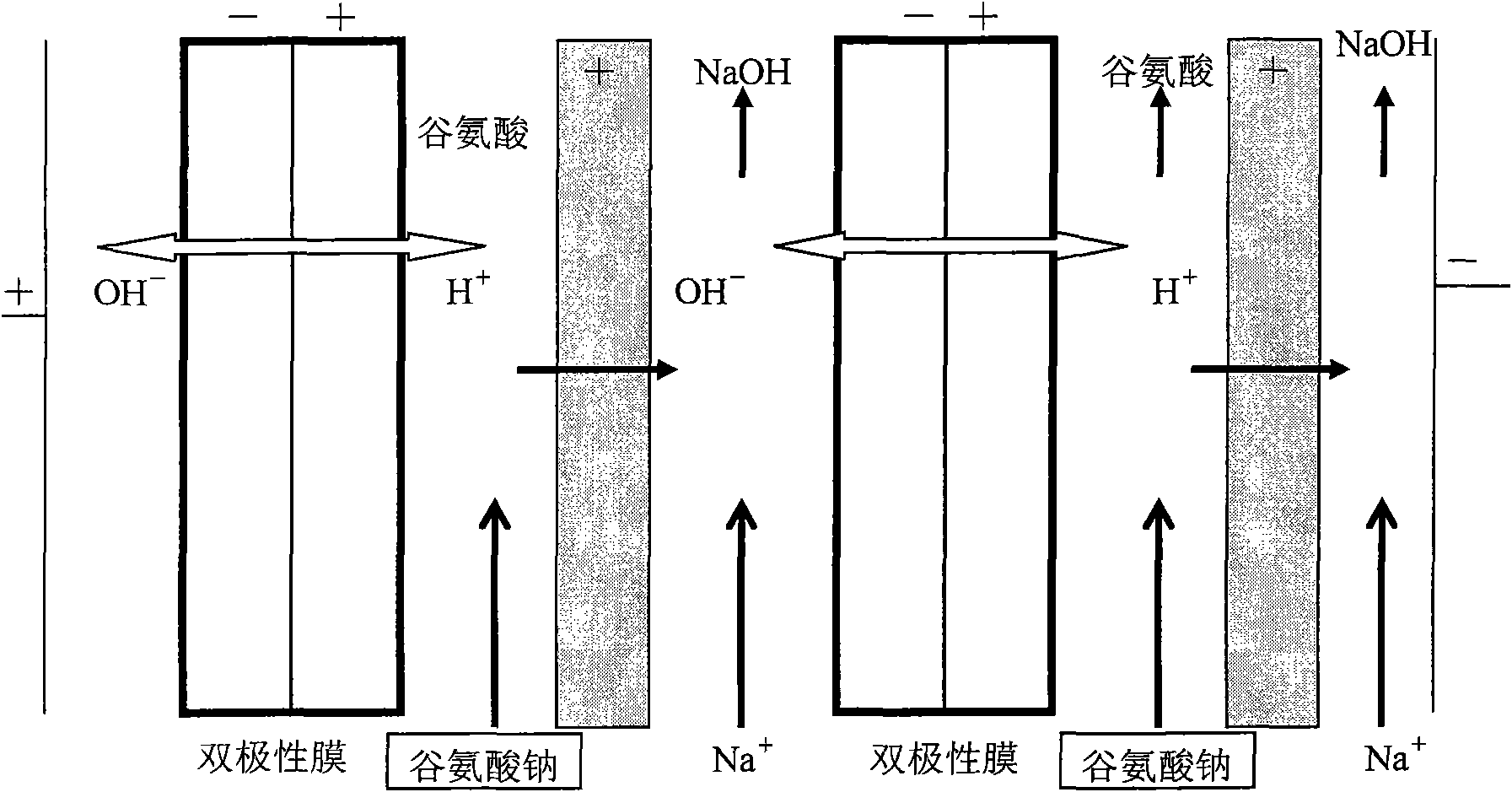

Method for extracting glutamic acid from glutamic acid fermentation liquor by bipolar membrane electroosmose process

A bipolar membrane and electrodialysis technology, applied in the direction of microorganism-based methods, fermentation, chemical instruments and methods, etc., can solve the problems of environmental pollution, huge equipment, large acid consumption, etc., and achieve no environmental pollution, operation Convenience and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] a. Using Cory nebacterium glutamicum, in the fermentation tank, according to the raw material ratio (weight percentage): starch hydrolyzed sugar 7.5%, corn syrup 0.3%, magnesium sulfate (MgSO 4 ·7H 2 O) 0.03%, disodium hydrogen phosphate (Na 2 HPO 4 ) 0.085%, urea 0.85%, potassium chloride (KCl) 0.01%. In the fermentation process, the inoculum amount of bacteria was 0.8%, 90.425% of water was added, the aeration and stirring fermentation, the temperature was controlled at 30°C, the pH value was 6.5, and the fermentation broth of glutamic acid was obtained after 20 hours of fermentation;

[0018] b. After the glutamic acid fermentation broth obtained in step a is neutralized with sodium hydroxide (NaOH), a sodium glutamate solution is obtained, and the strain and macromolecular proteins are retained in the membrane by ultrafiltration, and the small molecular glutamate Sodium oozes through the membrane to obtain a 2.39% sodium glutamate solution.

[0019] c. Perform bipolar m...

Embodiment 2

[0021] The producing bacteria is Brevibacterium, according to the ratio of raw materials: starch hydrolyzed sugar 8.5%, corn steep liquor 0.6%, magnesium sulfate (MgSO 4 ·7H 2 O) 0.06%, disodium hydrogen phosphate (Na 2 HPO 4 ) 0.17%, urea 1.7%, potassium chloride (KCl) 0.03%, the amount of bacteria inoculated during the fermentation process is 1%, add water 87.94%, in the fermentation tank, aeration and stirring fermentation, temperature control at 34 ℃, pH 6.8 After 30 hours of fermentation, it was neutralized with NaOH, and a solution containing 4.30% sodium glutamate was obtained by ultrafiltration. The bipolar membrane electrodialysis is used for separation, activated carbon is decolorized, and concentrated and crystallized to obtain the finished glutamic acid.

Embodiment 3

[0023] The producing bacteria is Corynebacterium beijing, according to the raw material ratio: starch hydrolyzed sugar 8.5%, corn syrup 0.45%, magnesium sulfate (MgSO 4 ·7H 2 O) 0.045%, disodium hydrogen phosphate (Na 2 HPO 4 ) 0.10%, urea 1.5%, potassium chloride (KCl) 0.015%, the bacterial inoculum in the fermentation process is 0.9%, add water 88.49%, in the fermentation tank, aeration and stirring fermentation, temperature control at 34 ℃, pH 7.0 After 28 hours of fermentation, it was neutralized with NaOH, and a solution containing 4.17% sodium glutamate was obtained by ultrafiltration. The bipolar membrane electrodialysis is used for separation, activated carbon is decolorized, and concentrated and crystallized to obtain the finished glutamic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com