Method for preparing N-hydroxylamine hydrochloride by hydrolyzing N-nitromethane

A technology for nitromethane and hydroxylamine hydrochloride, applied in the directions of hydroxylamine, nitrogen and non-metallic compounds, can solve the problems of complex synthesis steps, inability to large-scale production, high energy consumption, etc., and achieve easy availability of raw materials, product purity and abundance. And the effect of high yield and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

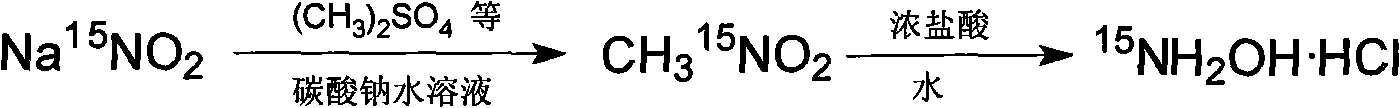

[0026] A sort of 15 Preparation of N-nitromethane by hydrolysis 15 The method for N-hydroxylamine hydrochloride, the method may further comprise the steps:

[0027] (1) 15 Preparation of N-nitromethane

[0028] In a 500ml three-neck flask equipped with a magnetic stirrer, a thermometer and a dropping funnel, add an aqueous solution of anhydrous sodium carbonate (2g of anhydrous sodium carbonate dissolved in 20ml of water) and 8.8g (0.126mol) 15 N-sodium nitrite, the temperature of the mixture was lowered to 10°C, under vigorous stirring, 12ml (0.126mol) dimethyl sulfate was added dropwise within 30 minutes, after the addition was completed, the temperature was raised to 40°C, and reacted for 4h, Heating up and distilling under reduced pressure, the distilled liquid is separated by a water separator, and the lower layer is 15 N-nitromethane;

[0029] (2) 15 Preparation of N-hydroxylamine hydrochloride

[0030] In a 500ml three-neck flask equipped with magnetic stirring, ...

Embodiment 2

[0032] A sort of 15 Preparation of N-nitromethane by hydrolysis 15 The method for N-hydroxylamine hydrochloride, the method may further comprise the steps:

[0033] (1) 15 Preparation of N-nitromethane

[0034] In a 500ml three-neck flask equipped with magnetic stirring and a thermometer, add an aqueous solution of anhydrous sodium carbonate (2g of anhydrous sodium carbonate dissolved in 20ml of water) and 8.8g (0.126mol) 15 N-sodium nitrite, lower the temperature of the mixture to 5°C, under vigorous stirring, add 24g (0.252mol) chloroacetic acid within 30 minutes, after the addition, the temperature rises to 20°C, react for 6h, then heat up and distill under reduced pressure , the distilled liquid is separated by a water separator, and the lower layer is 15 N-nitromethane;

[0035] (2) 15 Preparation of N-hydroxylamine hydrochloride

[0036] In a 500ml three-neck flask equipped with magnetic stirring, thermometer and reflux condenser, add 6.83g (0.11mol) 15 N-nitrome...

Embodiment 3

[0038] A sort of 15 Preparation of N-nitromethane by hydrolysis 15 The method for N-hydroxylamine hydrochloride, the method may further comprise the steps:

[0039] (1) 15 Preparation of N-nitromethane

[0040] In a 500ml three-neck flask equipped with a magnetic stirrer, a thermometer and a dropping funnel, add an aqueous solution of anhydrous sodium carbonate (2g of anhydrous sodium carbonate dissolved in 20ml of water) and 8.8g (0.126mol) 15 N-sodium nitrite, the temperature of the mixture was lowered to 8°C, and under strong stirring, 32ml (0.252mol) methyl iodide was added dropwise within 30 minutes. Distillation under reduced pressure, the distilled liquid is separated by a water separator, and the lower layer is 15N-nitromethane;

[0041] (2) 15 Preparation of N-hydroxylamine hydrochloride

[0042] In a 500ml three-neck flask equipped with magnetic stirring, thermometer and reflux condenser, add 6.83g (0.11mol) 15 N-nitromethane, 5ml water and 24ml (0.279mol) co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com