Titanium alloy electrochemical oxidation liquid

An oxidizing solution and electrochemical technology, applied in the field of oxidizing solution, can solve the problems of poor promotion of anodic oxide film thickening, weak promotion of pitting resistance, unsatisfactory anodic oxide film thickness, etc. Thickness, improvement of pitting resistance, effect of changing composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Slowly add 180g of sulfuric acid into 540g of water along the wall of the glass container and stir while adding to form an acid solution; dissolve 50g of cerium sulfate in 225g of water and stir until completely dissolved to form a cerium salt solution; then slowly add the acid solution to the cerium salt In the solution, stir continuously to form a mixed solution; add 5 g of sodium dodecylbenzenesulfonate to the mixed solution, and stir until uniform to obtain the required 1 Kg electrochemical oxidation solution of the present titanium alloy.

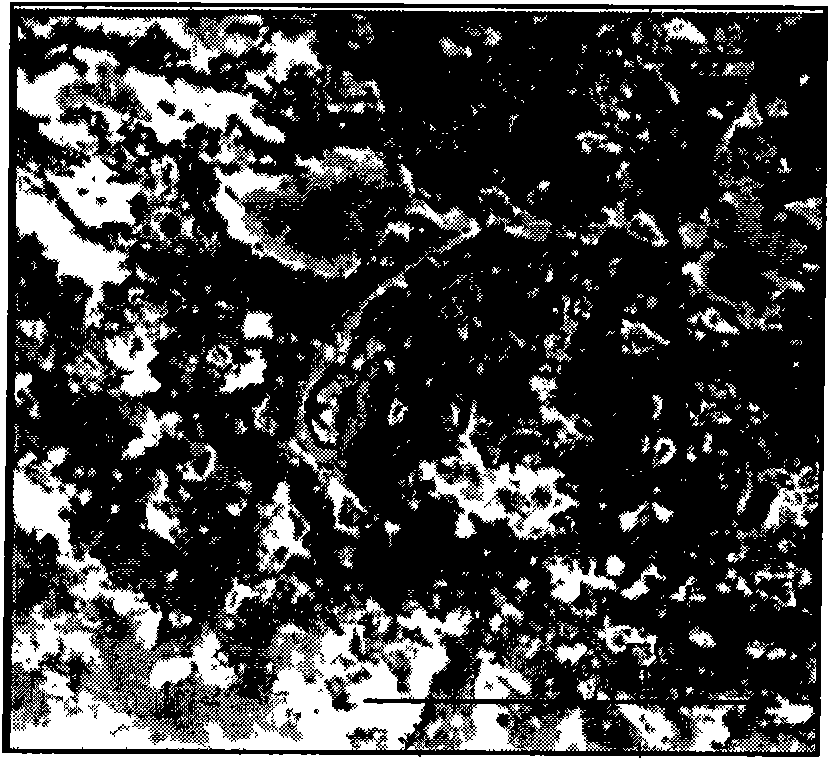

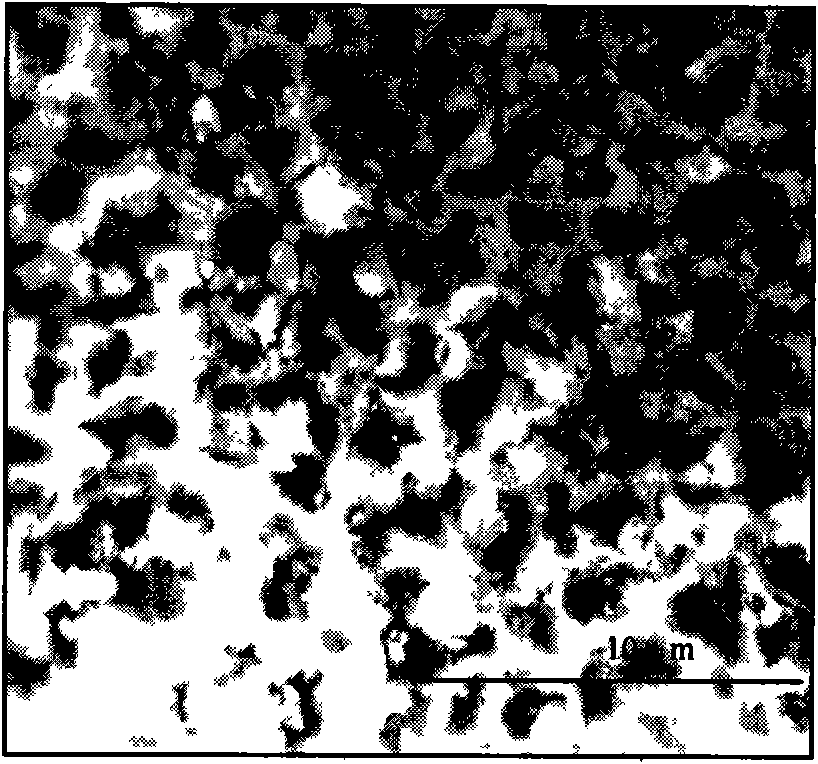

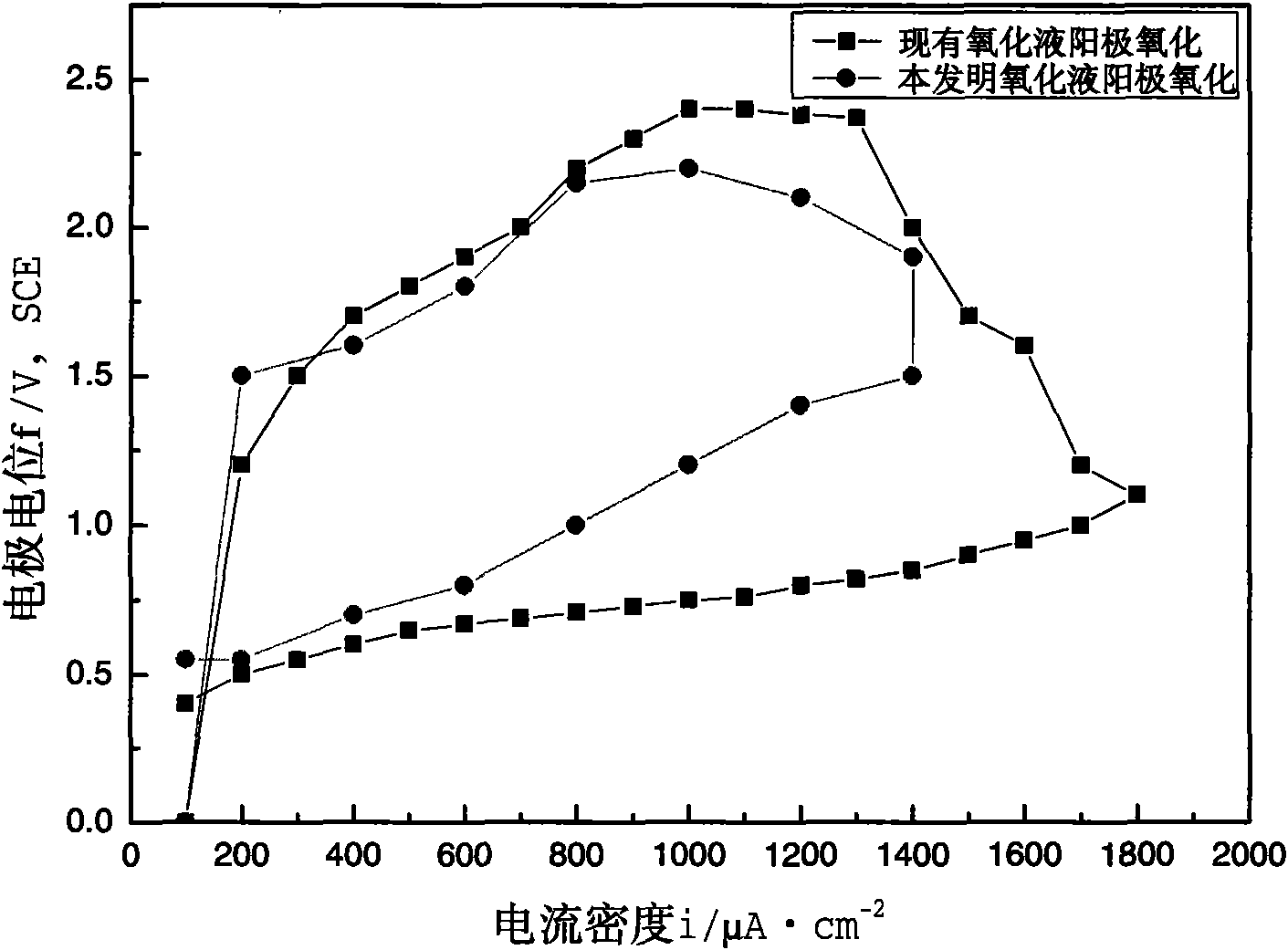

[0023] see figure 1 , figure 2 , compared to figure 1 For the anodized film on the surface of medium titanium alloy, figure 2 The compactness of the anodized film on the surface of the medium-titanium alloy is improved and the defects are less. right figure 2 The anodized film on the surface of the titanium alloy is analyzed by energy spectrum, and the results are: Ti 27% (atom), O 60% (atom), Ce 10% (atom), and other ele...

Embodiment 2

[0028] Slowly add 190g of hydrochloric acid into 570g of water along the wall of the glass container and stir while adding to form an acid solution; dissolve 70g of cerium nitrate in 164g of water and stir until completely dissolved to form a cerium salt solution; then slowly add the acid solution to the cerium salt In the solution, stir continuously to form a mixed solution; add 6 g of sodium dodecylbenzenesulfonate to the mixed solution, and stir until uniform to obtain the required 1 Kg electrochemical oxidation solution of the present titanium alloy.

[0029] see Figure 4 , Figure 5 , at the same film-forming voltage, Figure 4 The thickness of anodized film on the surface of medium titanium alloy is less than one micron, while Figure 5 The thickness of the anodized film on the surface of the titanium alloy is more than two microns. It can be seen that, Figure 5 The thickness of the anodized film on the surface of the medium-titanium alloy has been significantly incre...

Embodiment 3

[0031] Slowly add 200g of citric acid into 600g of water along the wall of the glass container and stir while adding to form an acid solution; dissolve 90g of cerium sulfate in 102g of water and stir until completely dissolved to form a cerium salt solution; then slowly add the acid solution to the cerium In the salt solution, stir continuously to form a mixed solution; add 8 g of sodium dodecylbenzenesulfonate to the mixed solution, stir until uniform, and obtain the required 1Kg electrochemical oxidation solution of the present titanium alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com