Civil air defence electromagnetic shielding coating and preparation method thereof

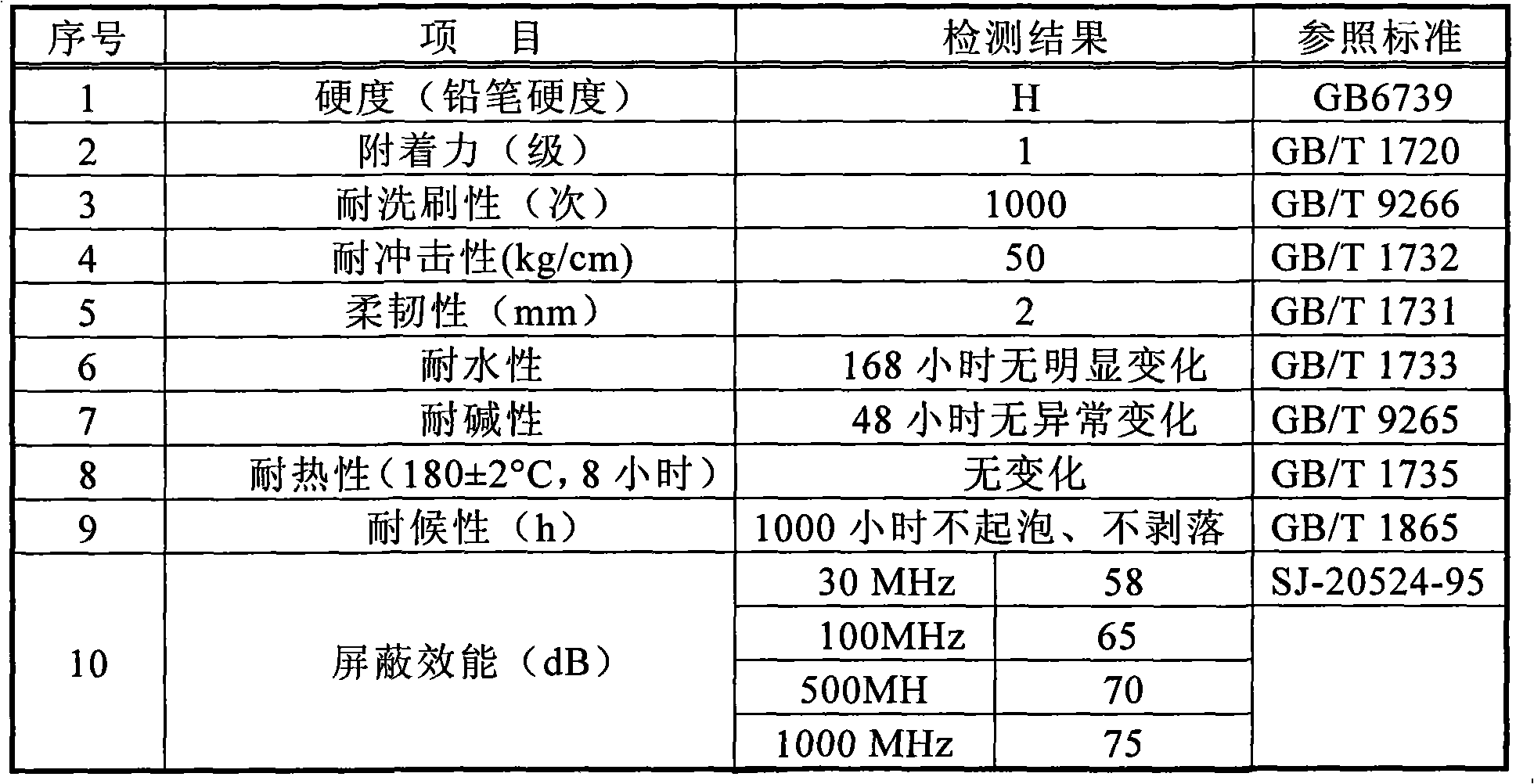

A technology for electromagnetic shielding coatings and civil air defense projects, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor electromagnetic shielding, poor high-frequency shielding effect, and reduced conductivity, and achieve wide shielding frequency band and good shielding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Oily primer

[0043] Acrylic modified silicone resin 35kg, electroless silver-plated carbon fiber 28kg, conductive polyaniline 8kg, leveling agent 0.5kg, dispersant 0.5kg, defoamer 0.2kg, anti-sedimentation agent 4kg, the mass ratio is 1:1:2 Add 23.8kg of the mixed solvent of butyl acetate, ethyl acetate and No. 200 solvent oil to the high-speed disperser, disperse at high speed for 30 minutes, and sand it three times with a sand mill until the fineness is 100um.

[0044] (2) Oily finish

[0045] 45kg of acrylic modified silicone resin, 5kg of modified nano-indium tin oxide, 1kg of dispersant, 0.5kg of leveling agent, 4kg of anti-sedimentation agent, 0.3kg of defoamer, and butyl acetate with a mass ratio of 1:1:2 , ethyl acetate and No. 200 solvent oil mixed solvent 44.2kg, put into the dispersing barrel, disperse with ultrasonic wave for 1.5h, and check that the transmittance reaches 75%.

[0046] The method of painting is spraying. First, clean the object to be...

Embodiment 2

[0048] (1) Water-based primer

[0049] Put 23kg of water and 0.5kg of 250HBR cellulose into a high-speed disperser to disperse for 30 minutes, then add 35kg of chemically silver-plated carbon fiber, 8kg of conductive polyaniline, 0.6kg of leveling agent, 0.5kg of dispersant, and 0.4kg of defoamer, and disperse at high speed. Disperse for 1 hour, add 32kg of water-based acrylic resin, and mix slowly for 30 minutes.

[0050] (2) Water-based topcoat

[0051] Put 42.7kg of water and 0.5kg of 250HBR cellulose into the dispersion bucket to disperse for 30 minutes, then put 5kg of modified nano-indium tin oxide, 1kg of dispersant, 0.5kg of leveling agent, 0.3kg of defoamer, and 50kg of water-based polyurethane resin, Put it into the dispersing barrel and disperse it with ultrasonic waves for 1.5h, and then check that the transparency reaches 75%.

[0052] The method of application is roller coating. First, clean the object to be coated so that there is no dust, no oil, and no rust...

Embodiment 3

[0054] (1) Oily primer

[0055] 35kg of epoxy-modified silicone resin, 32kg of electroless silver-plated carbon fiber, 8kg of conductive polyaniline, 0.8kg of leveling agent, 1kg of dispersant, 0.2kg of defoamer, 3kg of anti-sedimentation agent, the mass ratio is 1:1:2 Add 20kg of the mixed solvent of butyl acetate, ethyl acetate and No. 200 solvent oil to a high-speed disperser for high-speed dispersion for 50 minutes, and sand it three times with a sand mill until the fineness reaches 100um.

[0056] (2) Oily finish

[0057]50kg of epoxy-modified silicone resin, 5kg of modified nano-tin antimony oxide, 1.2kg of dispersant, 0.5kg of leveling agent, 3.8kg of anti-sedimentation agent, 0.4kg of defoamer, and a mass ratio of 1:1:2 Put 39.1kg of mixed solvent of butyl acetate, ethyl acetate and No. 200 mineral spirits into the dispersion bucket, disperse with ultrasonic waves for 1.6h, and check that the transmittance reaches 80%.

[0058] The brushing method adopts brushing. F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com