Tebuconazole-thiram sterilizer composition

A technology of fumetidine and tebuconazole, applied in the directions of fungicides, biocides, biocides, etc., can solve the problems of short duration of effect, low utilization rate, etc., to reduce the dosage, reduce the degree of influence, prevent and protect the treatment effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

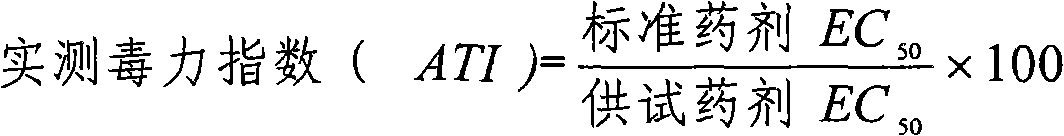

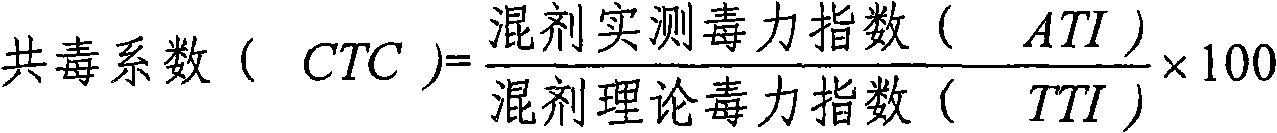

Method used

Image

Examples

Embodiment 1

[0022] Weigh 9% of the original powder of tebuconazole, 73% of the original powder of thiram, 4% of the dispersant sodium naphthalenesulfonic acid formaldehyde condensate, 2% of the wetting agent sodium lauryl bisulfate, 2% of the pulling powder, and disintegrate 4% decomposed modified starch, 2% carrier kaolin; it is mixed according to the general method, and after stirring evenly, it is pulverized by an airflow mill to obtain mother powder, and the mother powder is mixed with 4% binder sodium polyacrylate 80, and then Granulate, dry, and sieve to obtain about 96% of 80% tebuconazole and thiram water dispersible granules. The content of active ingredients after inspection is tebuconazole 8.2% thiram 72.4%, moisture ≤ 2.5%, pH value 7.4 sieve (through 75um sieve) ≥ 8%, suspension rate ≥ 65%, persistent foaming (1min) ≤ 10mL , wettability ≤ 1min, dust ≤ 3.0%, accelerated heat storage stability qualified.

Embodiment 2

[0024] Weigh 12% of the original powder of tebuconazole, 70% of the original powder of thiram, 3% of the dispersant lignosulfonate, 3% of the wetting agent sodium butylnaphthalene sulfonate, 1% of sodium dodecyl hydrogen sulfate, and disintegrate Glucose 4% of solution agent, 3% of carrier white carbon black; It is mixed by general method, after stirring evenly, pulverizes to obtain mother powder through jet mill, mother powder is mixed with 4% binder sodium polyacrylate 80, Then granulate, dry, and sieve to obtain about 96% of 80% tebuconazole and thiram water dispersible granules. After testing, the active ingredient content is difenoconazole 11% thiram 69%, moisture ≤ 2.5%, pH value 7.2 sieve (through 75um sieve) ≥ 98%, suspension rate ≥ 65%, long-lasting foaming (1min) ≤10mL, wettability ≤1min, dust ≤3.0%, qualified for accelerated thermal storage stability.

Embodiment 3

[0026] Weigh 16% of the original powder of tebuconazole, 66% of the original powder of thiram, 3% of the dispersant sodium naphthalenesulfonate formaldehyde condensate, 1% of the wetting agent sodium lauryl hydrogensulfate, 2.5% of the pulling powder, and disintegrate Debonding agent ammonium sulfate 5.5%; It is mixed according to the general method, after stirring evenly, pulverizes through jet mill to obtain mother powder, mother powder is mixed with 6% binder carboxymethyl cellulose, then granulated, Dried and sieved to obtain about 96% of 80% difenoconazole and thiram water dispersible granules. The content of active ingredients tested is tebuconazole 15% thiram 65%, moisture ≤ 2.5%, pH value 7.6 sieve (through 75um sieve) ≥ 98%, suspension rate ≥ 65%, persistent foaming (1min) ≤ 10mL , wettability ≤ 1min, dust ≤ 3.0%, accelerated heat storage stability qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com