Polyurethane elastic yarn and method for production thereof

A technology of polyurethane and elastic yarn, which is applied in the manufacture of rayon, single-component synthetic polymer rayon, and fiber chemical characteristics. It can solve the problems of low elongation and poor heat resistance of elastic fibers, and achieve high resilience, Ease of putting on and taking off and excellent color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

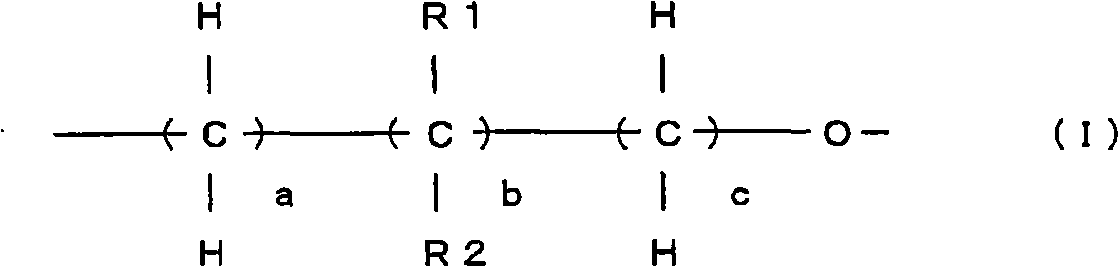

[0061] When the main structural components of polymer diol and diisocyanate polyurethane are prepared into polyurethane elastic yarn according to the preparation method of the present invention, the above-mentioned polymer having sulfo groups must be added. The polymer having a sulfo group can be added at the polymerization stage of the polyurethane, but for the purpose of the present invention, it is preferably added after the polyurethane solution is prepared first.

[0062] The polyurethane solution or the polyurethane as a solute in the solution may be prepared by melt polymerization or solution polymerization methods or other methods. However, solution polymerization is preferred. In the case of solution polymerization, no gel or other foreign matter is produced in polyurethane, which makes spinning easier and facilitates the production of low-fiber polyurethane filaments. Using solution polymerization also has the advantage of eliminating the solution preparation step. ...

Embodiment 1

[0132] A 35% by weight DMAc solution of a polyurethane polymer (a1) composed of PTMG with a number average molecular weight of 2900, MDI and ethylene glycol was polymerized by a conventional method to prepare a polymer solution A1.

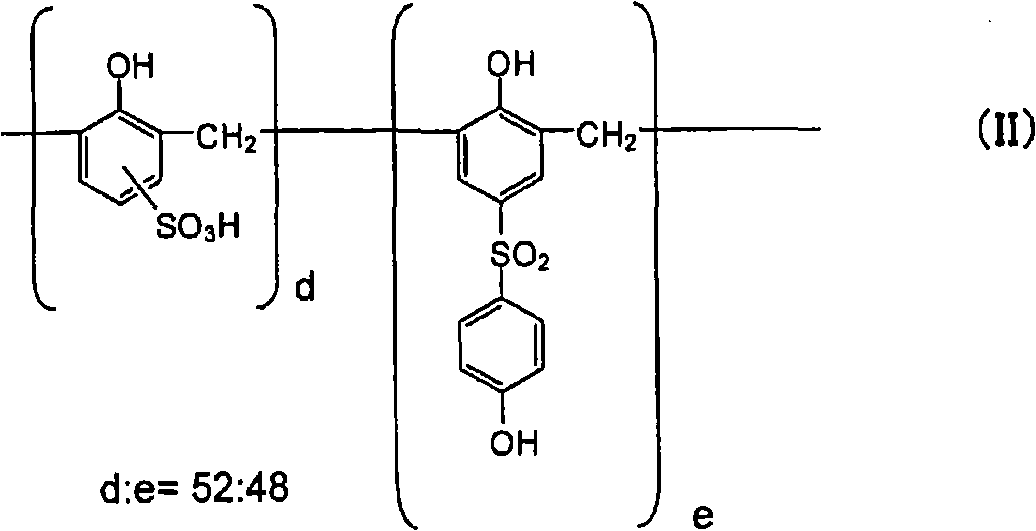

[0133] Then, the molar ratio of phenolsulfonic acid and 4,4'-dihydroxydiphenyl sulfone is 52:48 (molar concentration 52%) shown in the formaldehyde condensation polymer (b1) shown in the chemical formula (II) as the compound with sulfo group Copolymer, prepare its DMAc solution.

[0134]

[0135] To prepare the DMAc solution, use a horizontal mill DYNO-MIL KDL (manufactured by Willy A. Bachofen Co.), fill the mill with 85% zirconium beads and perform uniform microdispersion at a flow rate of 50 g / min to prepare a compound with a sulfo group DMAc solution B1 (35% by weight) of the copolymer of .

[0136] Then, as an antioxidant, a polyurethane solution (Dupont Methacrole TM 2462, c1) and polycondensates of p-cresol and divinylbenzene (Dupont ...

Embodiment 2

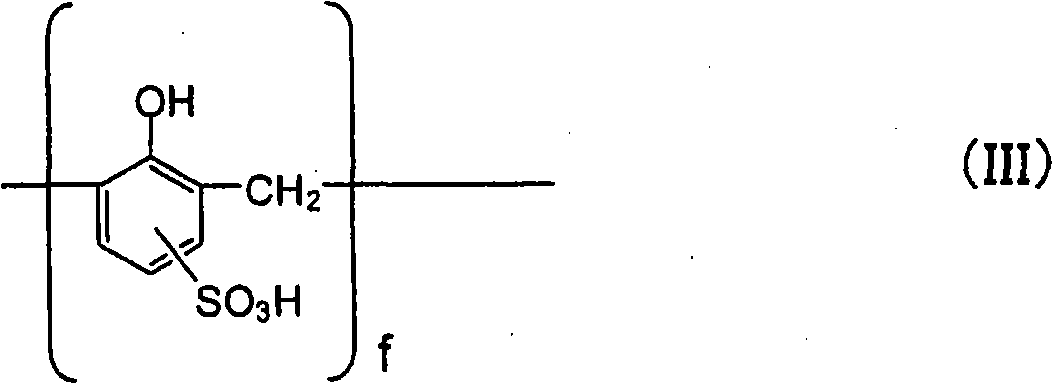

[0144] A formaldehyde polycondensate (b2) of phenolsulfonic acid represented by chemical formula (III) was used as a copolymer of a compound having a sulfo group. This was prepared as a microdispersion of DMAc.

[0145]

[0146] A microdispersion was prepared in a manner similar to that used in Example 1, a DMAc dispersion B2 (35% by weight) of a polymer of a compound having a sulfo group was prepared. 92% by weight, 5% by weight and 3% by weight of the polymer solution A1 of Example 1, the copolymer solution B2 of the copolymer containing the above-mentioned monomer having a sulfo group, and other additive solutions C1 were uniformly mixed to prepare spinning Silk solution D2.

[0147] Dry spinning was carried out using a spinning solution at a speed ratio of godet roll to reel of 1.40 and a spinning speed of 540 m / min to produce polyurethane elastic yarn (200 g bobbin) of 20 dtex , a monofilament, and a copolymer containing 5% by weight of a compound having a sulfo grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| draft ratio | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com