Laboratory waste water treatment method and device

A wastewater treatment, laboratory technology, applied in water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of high power consumption, easy saturation of activated carbon, high pressure, etc., and achieve rapid treatment , The effect of reducing COD and reducing equipment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. Target wastewater

[0054] The waste water to be treated is the waste water generated during the experiment of the Import and Export Inspection Bureau, and the waste water treatment capacity is 2 tons / day. The influent COD varies greatly, between 100-8000mg / L, and the pH range is 0-7. The main component of wastewater is organic matter, and contains trace amounts of organic lead, manganese, copper, zinc, chromium, etc.

[0055] 2. Process parameters

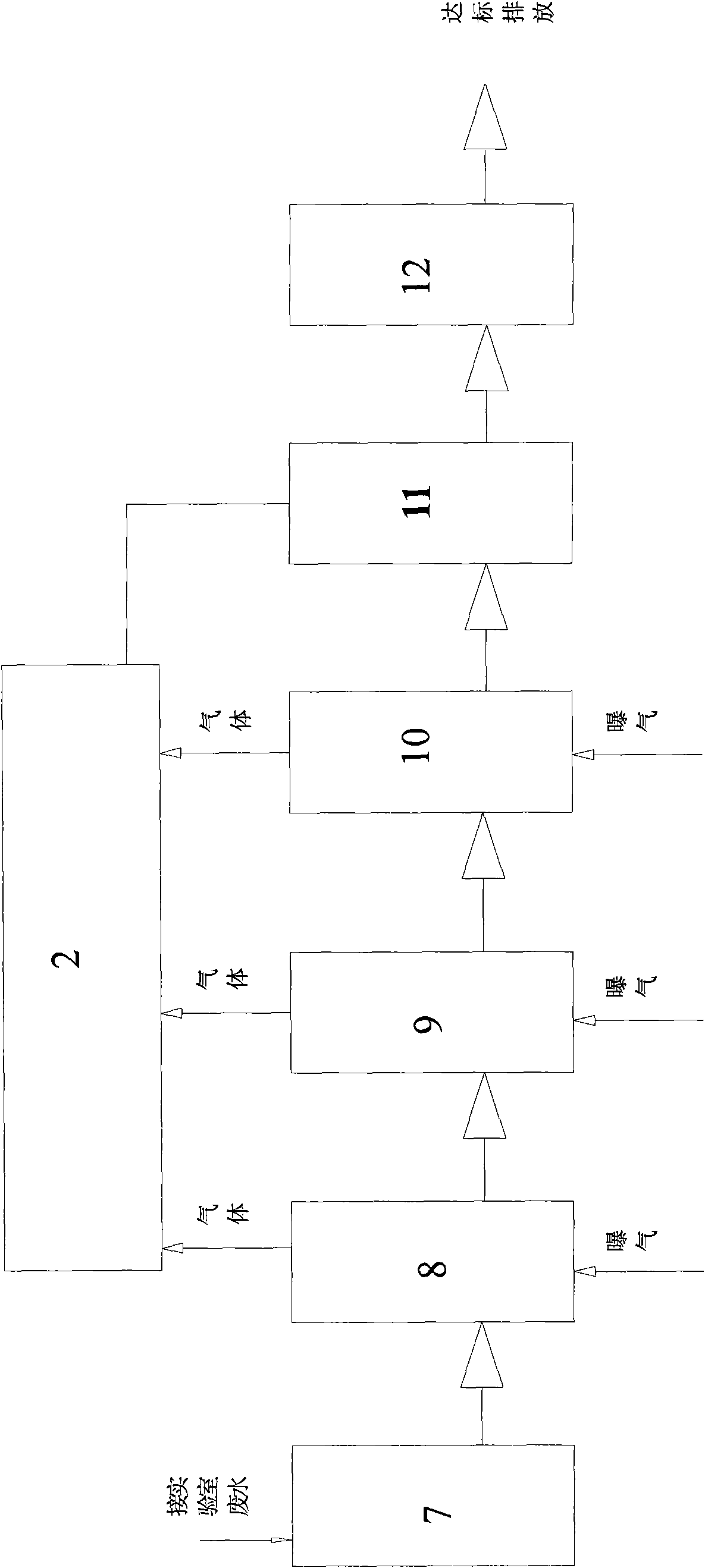

[0056] use as figure 2 and image 3 For the shown device, the specific process parameters are as follows:

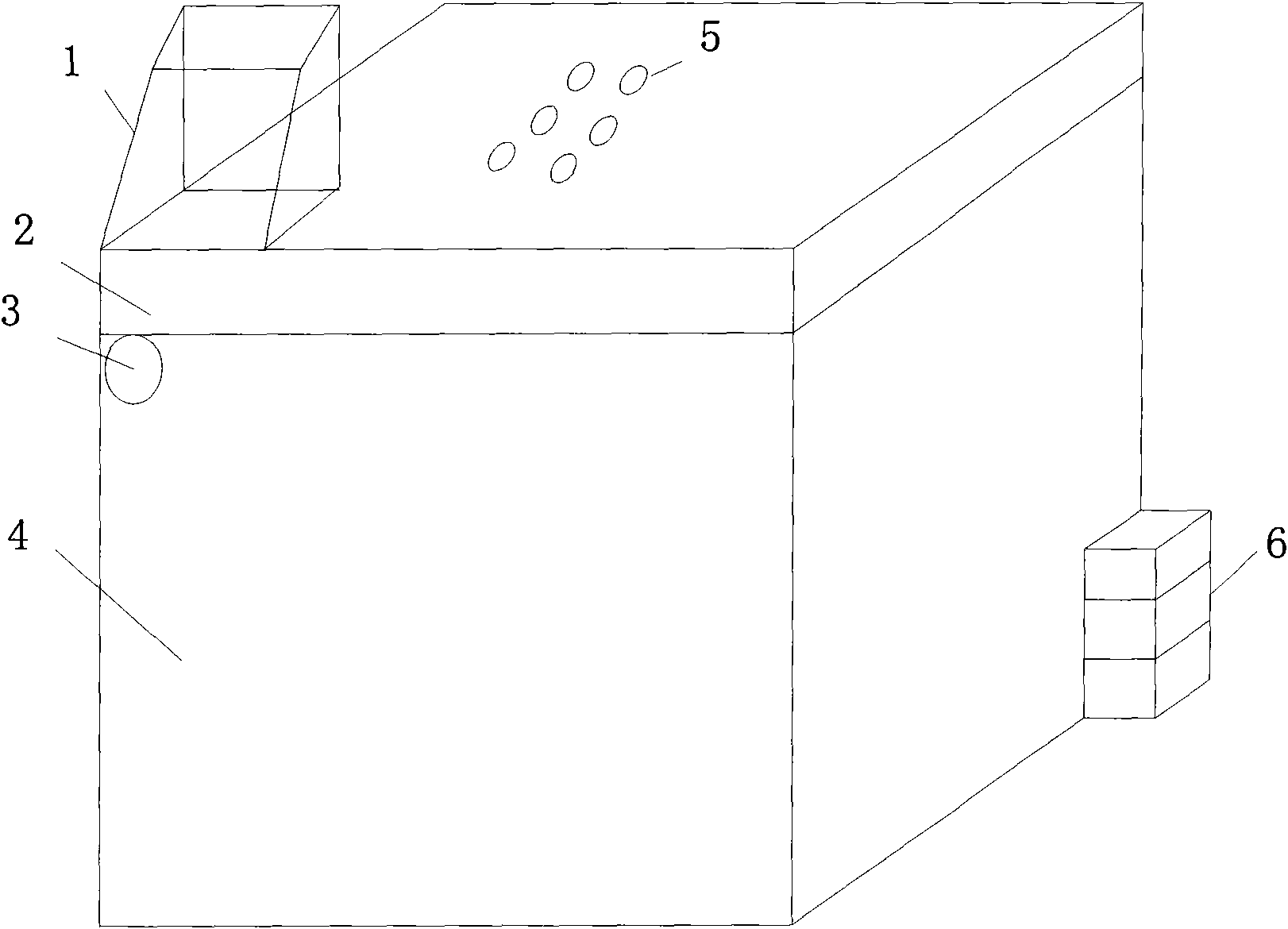

[0057] (1) Sludge filter tank 2: The thickness is 10cm, and the treatment capacity is designed according to 1 to 3 months each time.

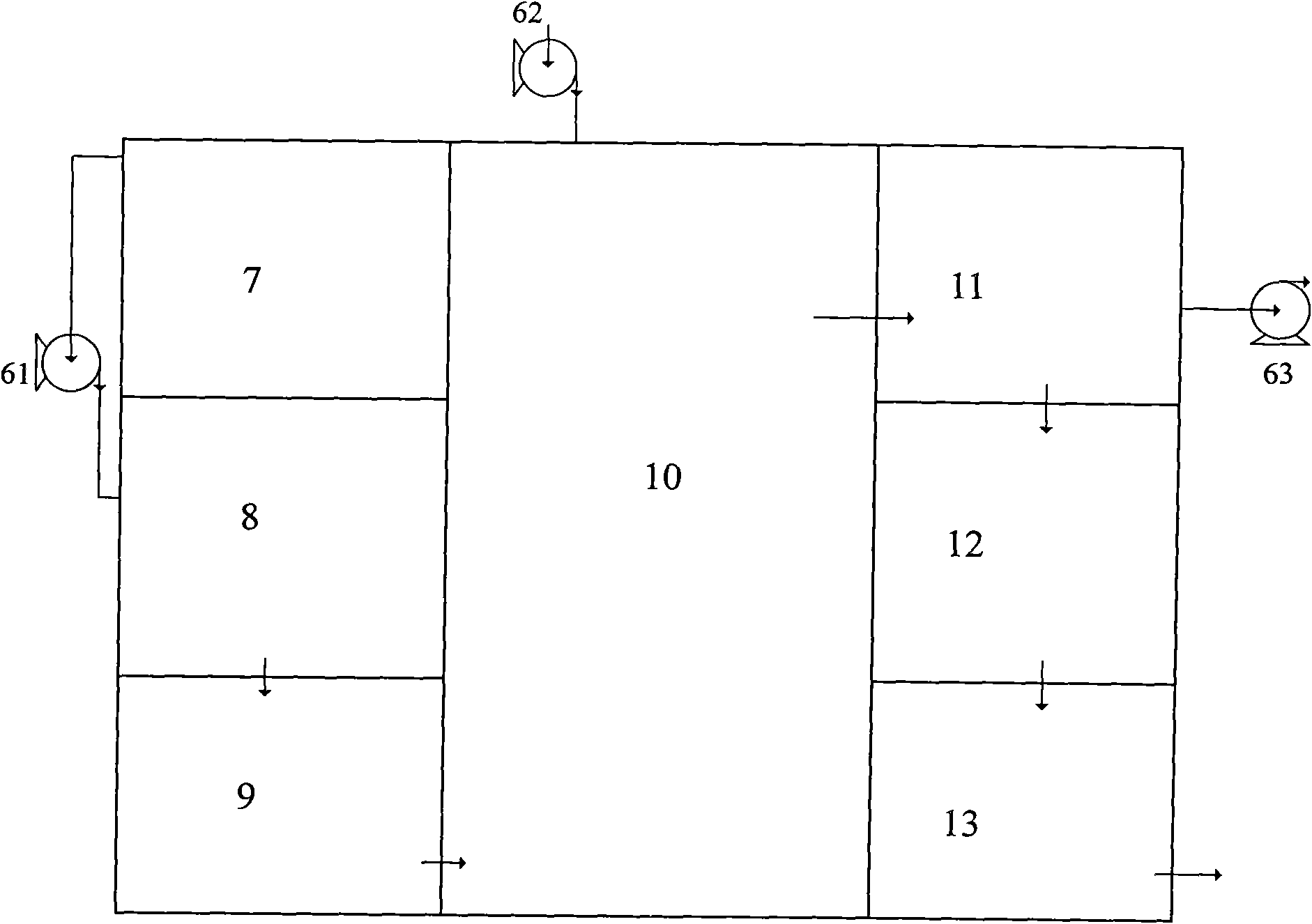

[0058] (2) Collecting tank 7: Set the high liquid level and low liquid level in the collecting tank, the high liquid level is 700mm from the ground, and the low liquid level is 100mm from the ground, controlled by the pressure transmission control system. When the water level...

Embodiment 2

[0072] 1. Target wastewater

[0073] In the dioxin laboratory, some dioxin-containing wastewater is discharged from time to time. The wastewater is very toxic, almost impossible to biochemically, and difficult to be oxidized. The content of dioxin is 2~2000μg / L, COD Cr At around 100mg / L, the pH is slightly acidic.

[0074] 2. Process parameters

[0075] use as figure 2 and image 3 For the shown device, the specific process parameters are as follows:

[0076] (1) Sludge filter pond 2: same as embodiment 1.

[0077] (2) Collecting pool 7: same as embodiment 1.

[0078] (3) Inner electrolytic cell 8: same as embodiment 1.

[0079] Electrolytic materials: calcium carbonate (2%), iron powder (60%), carbon powder (28%), magnesium phosphate salt (3%), polystyrene (4%), titanium dioxide (3%).

[0080] The preparation method of the electrolytic material: grind calcium carbonate, iron powder, carbon powder, magnesium phosphate salt, copper powder, titanium dioxide powder into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com