Catalyst for low-temperature denitration of power-plant flue gas by selective catalytic reduction (SCR) and preparation method thereof

A low-temperature denitrification and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of single component, no anti-SO2 poisoning ability, Oxide catalytic activity reduction and other problems, to achieve a good anti-SO2 poisoning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh a certain mass of cerium and metal iron or vanadium or chromium nitrate or acetate and tungsten-doped titanium dioxide and mix them uniformly in an aqueous solution, wherein the loading amount of cerium is 10%, and the molar ratio of cerium to variable-valent metal is 1.2. Stir mechanically for 2 hours to make it evenly mixed, put it in a drying oven after standing for 3 hours, and dry it at a temperature of 70-110°C for 4-8 hours, and then calcinate it in the air at 350-650°C, the calcining time After cooling for 3-6 hours, grind and sieve, and take the part of 40-60 mesh as the catalyst.

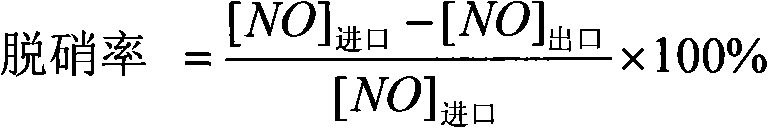

[0019] The test method for the SCR denitrification efficiency of the prepared catalyst is: put the prepared catalyst into a fixed-bed tubular reactor, and heat the reactor to the required reaction temperature with a tubular electric furnace. Simulated flue gas and reducing agent NH 3 into the reactor, where the composition of the simulated flue gas is N 2 , O 2 , NO / N 2 (N...

Embodiment 2

[0029] Weigh a certain mass of cerium and metal iron or vanadium or chromium nitrate or acetate and tungsten-doped titanium dioxide and mix them uniformly in the aqueous solution, wherein the loading amount of cerium is 4%, and the molar ratio of cerium to variable-valence metal is 1.5. Stir mechanically for 2 hours to make it evenly mixed, put it in a drying oven after standing for 3 hours, and dry it at a temperature of 70-110°C for 4-8 hours, and then calcinate it in the air at 350-650°C, the calcining time After cooling for 3-6 hours, grind and sieve, and take the part of 40-60 mesh as the catalyst.

[0030] The test method of catalyst activity is the same as embodiment 1, at reaction temperature 180 ℃, C NO =C NH3 =0.2%, C O2 = 5%, air speed = 40000h -1 Under certain test conditions, the catalytic reduction efficiency of the catalyst remains above 80%.

Embodiment 3

[0032] Weigh a certain mass of cerium and metal iron or vanadium or chromium nitrate or acetate and tungsten-doped titanium dioxide and mix them uniformly in an aqueous solution, wherein the loading amount of cerium is 8%, and the molar ratio of cerium to variable-valence metal is 1.8. Stir mechanically for 2 hours to make it evenly mixed, put it in a drying oven after standing for 3 hours, and dry it at a temperature of 70-110°C for 4-8 hours, and then calcinate it in the air at 350-650°C, the calcining time After cooling for 3-6 hours, grind and sieve, and take the part of 40-60 mesh as the catalyst.

[0033] The test method of catalyst activity is the same as embodiment 1, at reaction temperature 180 ℃, C NO =C NH3 =0.2%, C O2 = 5%, air speed = 40000h -1 Under certain test conditions, the catalytic reduction efficiency of the catalyst remains above 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com