Methods for preparing L-tagatose

A technology for tagatose and glucose, applied in the field of preparing L-tagatose, can solve the problems of high price, unrealistic L-tagatose, regeneration of coenzyme factors, etc., and achieves the effect of high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Acetobacillus suboxydis was cultured in a fermentation medium containing 1% D-galactitol

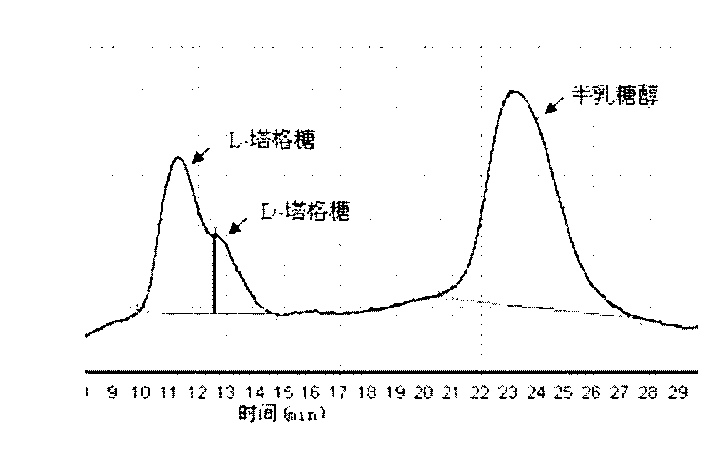

[0051] Acetobacter suboxydans was cultured in a seed medium at 30°C and 250 rpm for 48 hours to obtain a seed bacterial solution. Each liter of seed medium contains: 2 grams of D-galactitol (also called dulcitol or sweet alcohol); 5 grams of sorbitol; 10 grams of glucose; 10 grams of yeast powder; 2 grams of dipotassium hydrogen phosphate; 5 grams of calcium carbonate , Add water to 1 liter, pH 6.0. Then, 10 ml of the seed liquid was inoculated into 90 ml of fermentation medium, and cultured at 32° C. and 300 rpm for 24 hours. The composition of each liter of fermentation medium contains: 10 grams of D-galactitol; 1 gram of sorbitol; 10 grams of glucose; 10 grams of yeast powder; 2 grams of dipotassium phosphate; 5 grams of calcium carbonate. Add water to 1 liter. pH6.0. After the cultivation, the conversion rate and tagatose content were analyzed by HPLC, and the results were as ...

Embodiment 2

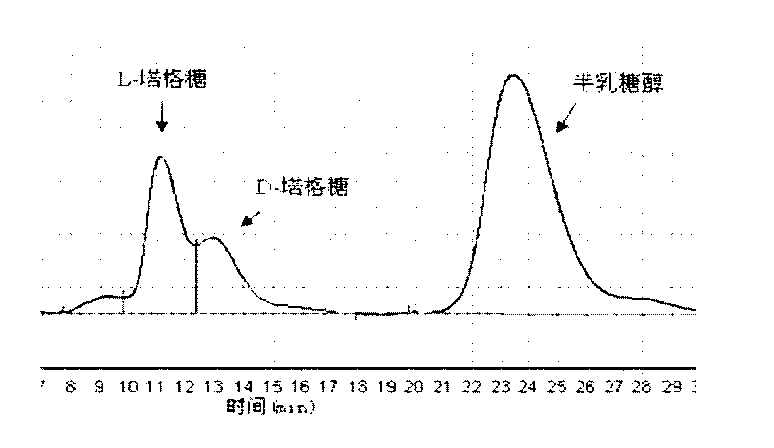

[0053] Acetobacillus suboxydis was cultured in a fermentation medium containing 4% D-galactitol

[0054] Acetobacter suboxydans was cultivated in a seed culture medium at 30° C. and 250 rpm for 48 hours to obtain a seed bacterial solution. Each liter of seed medium contains: 4 grams of D-galactitol; 2 grams of glycerol; 10 grams of glucose; 10 grams of yeast powder; 2 grams of dipotassium hydrogen phosphate; 10 grams of calcium carbonate. Add water to 1 liter, pH 6.0 . Then 10 ml of the seed liquid was inoculated into 90 ml of fermentation medium, and cultured at 32° C. and 300 rpm for 24 hours. The composition of each liter of fermentation medium contains: 40 grams of D-galactitol; 2 grams of sorbitol; 10 grams of glucose; 10 grams of yeast powder; 2 grams of dipotassium hydrogen phosphate; 5 grams of calcium carbonate. Add water to 1 liter. pH6.0. After the cultivation, the conversion rate and the content of tagatose were analyzed by HPLC. After integration calculation, the ...

Embodiment 3

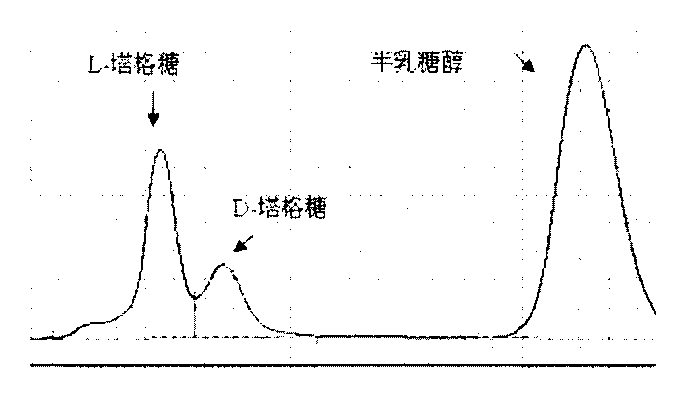

[0056] Acetobacter suboxydis was cultured in a fermentation medium containing 10% D-galactitol

[0057] Acetobacter suboxydis was cultured in a seed culture medium at 25° C. and 250 rpm for 48 hours to obtain a seed bacterial solution. Each liter of seed culture medium contains: 4 grams of D-galactitol; 2 grams of xylitol; 10 grams of glucose; 10 grams of yeast powder; 2 grams of dipotassium hydrogen phosphate; 10 grams of calcium carbonate, add water to 1 liter, pH 6 .0. Then 10 ml of the seed liquid was inoculated into 90 ml of fermentation medium, and cultured at 32° C. and 300 rpm for 48 hours. The composition of each liter of fermentation medium contains: 100 grams of D-galactitol; 5 grams of xylitol; 10 grams of glucose; 10 grams of yeast powder; 2 grams of dipotassium hydrogen phosphate; 5 grams of calcium carbonate, add water to 1 liter , PH6.0. After the cultivation, the conversion rate and the content of tagatose were analyzed by HPLC. After integration calculation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com