Radionuclide-labelled biodegradable bioabsorbable biopolymer nano fibrous membrane, preparation process and application thereof

A biopolymer and nanofiber membrane technology, applied in radioactive carriers, fiber treatment, fiber chemical characteristics, etc., can solve the problem of killing tumor cells but rarely reported in the literature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

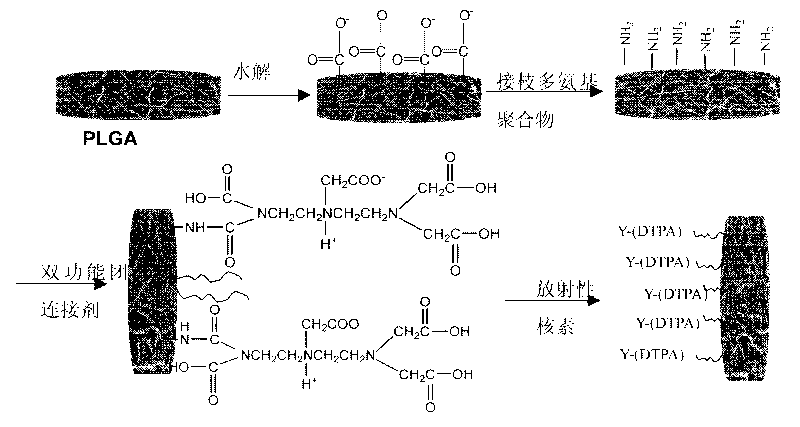

Method used

Image

Examples

Embodiment 1

[0050] (1) Preparation of solution: PLGA (LA / GA=50 / 50 (molar ratio), molecular weight 100,000) is dissolved in N, N dimethylformamide (DMF) and acetone (volume ratio is 5 / 5) In 10 ml of the mixed solvent, a PLGA solution with a concentration of 20 wt % was obtained, and the obtained PLGA solution was placed in a feeding syringe of an electrospinning device.

[0051] (2) Adjust the electrospinning device: select the double spinneret device connected with the injector, and the rotating drum is used as a collector; adjust the distance between the double spinneret and the rotating drum to be 12cm; the ambient temperature of spinning is 25 ℃, The air velocity in the environment is controlled at 0.5-0.8m 3 / hr; Turn on the high-voltage power supply and the feeding syringe pump, adjust the voltage to 20KV, and the feeding speed of the solution is 20ul / min for spinning, and obtain the PLGA nanofiber film on the rotating drum.

[0052] (3) After washing the collected PLGA nanofiber me...

Embodiment 2

[0058] (1) Utilize the PLGA nanofiber membrane prepared in embodiment 1.

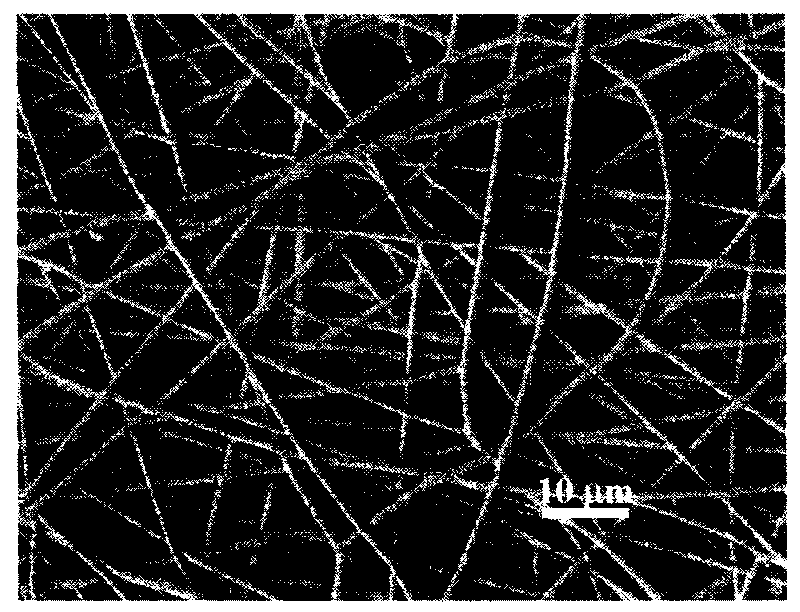

[0059] (2) Cut the dried electrospun PLGA nanofiber membrane into 2.25cm 2 Place the small piece of NaOH solution with a concentration of 0.075M in 10ml, react at 0°C for 30 minutes, soak and rinse with deionized water repeatedly, and place it in 5ml containing 50mM EDC and NHS (molar ratio: 1:1). After the activation reaction at 4°C for 16 hours, rinse with deionized water, then put it into 5ml of gelatin aqueous solution containing 10mg / ml, carry out grafting reaction at 30°C for 8 hours, then soak and rinse with a large amount of deionized water . A biodegradable and bioabsorbable PLGA nanofiber membrane grafted with gelatin on the surface is obtained. Such as image 3 As shown, the morphology of the fibers after grafting GE remained good and was not significantly damaged.

[0060] (3) Place the biodegradable and bioabsorbable PLGA nanofibrous membranes grafted with gelatin on the obtained surfac...

Embodiment 3

[0064] (1) Preparation of solution: PCL (molecular weight 100,000) is dissolved in 10ml of a mixed solvent of DMF and acetone (volume ratio is 8 / 2), to obtain a PCL solution with a concentration of 20wt%, and the obtained PCL solution is placed in an electrostatic In the feeding syringe of the spinning equipment.

[0065] (2) The preparation process of electrospinning is the same as that in Example 1.

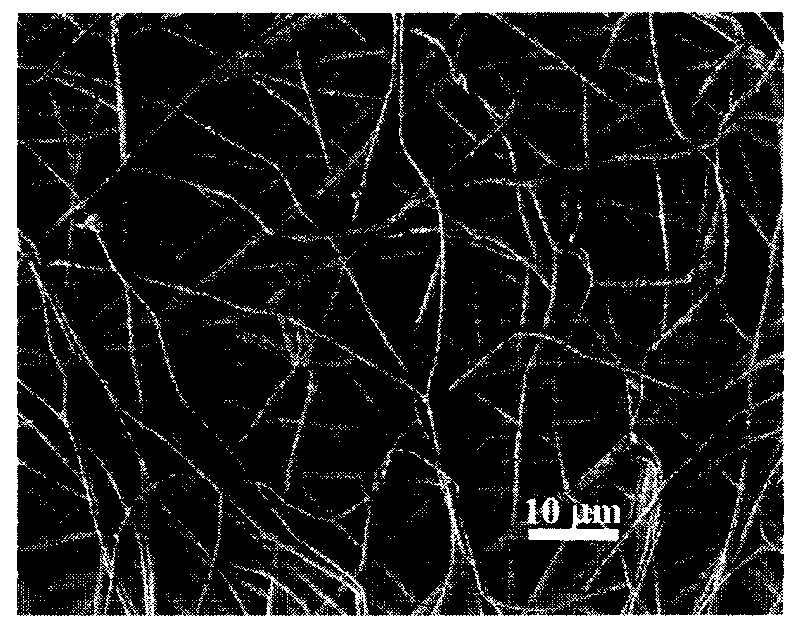

[0066] (3) After washing the collected PCL nanofiber membrane with deionized water repeatedly, after vacuum drying in a vacuum oven at 20°C for 5 hours, the biodegradable and absorbable PLGA nanofiber membrane material was obtained, and the thickness of the membrane was 104 Micron and nanofibers are arranged in a non-woven fabric structure, and the diameter of the nanofibers is between 500nm and 1 μm.

[0067] (4) Cut the dried electrospun PCL nanofiber membrane into 2.25cm 2 Put the small piece of NaOH solution with a concentration of 0.2M in 10ml, react at 0°C for 10 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com