Ultrasonic technology-based method for preparing microsphere and device thereof

A technology for preparing devices and microspheres, applied in the fields of microsphere preparation, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of restricting large-scale production, large consumption of water phase, small particle size of microspheres, etc. Industrialization prospect, good dispersion, small particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

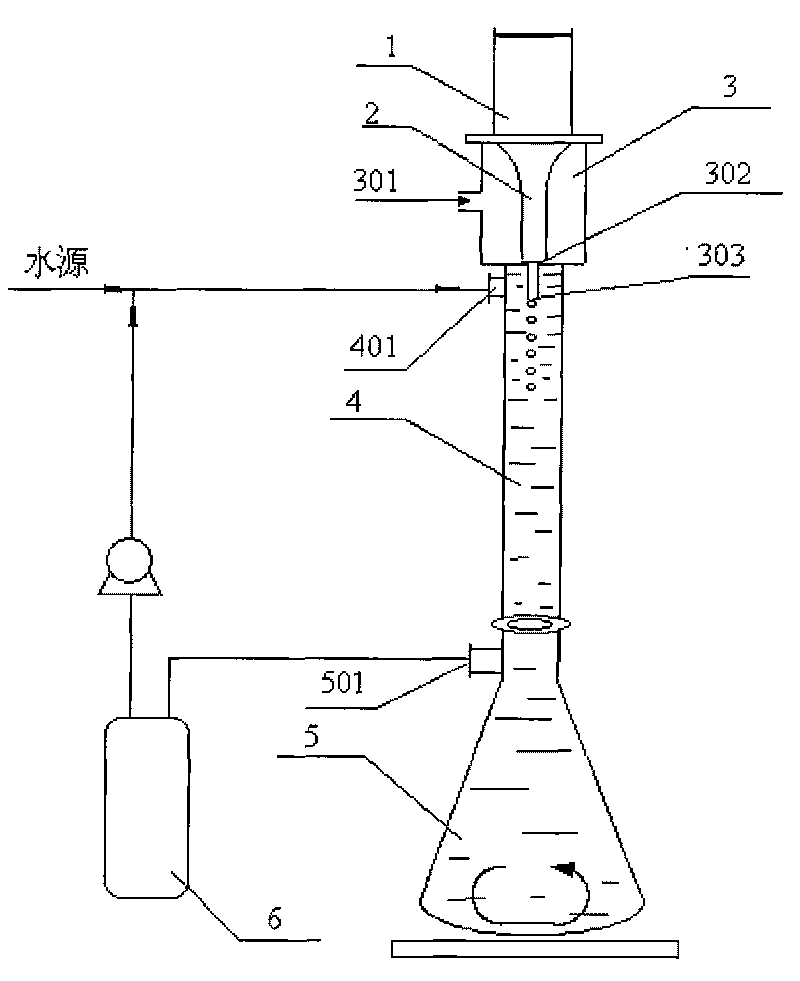

[0036] use figure 1 A device for preparing drug-containing microspheres, the effective height of the microsphere forming tube 4 is 50 cm, and the aperture of the small hole 302 is 50 μm;

[0037] First, the polyvinyl alcohol (PVA) aqueous solution with a concentration of 1 g / L is filled into the microsphere forming tube 4 and the microsphere solidifier 5, and the end of the nozzle 303 is inserted in the polyvinyl alcohol (PVA) aqueous solution;

[0038] Take 20g of donepezil (the second-generation acetylcholinesterase inhibitor, used for the treatment of Alzheimer's disease) and 80g of poly(lactic-co-glycolic acid) (PLGA), and dissolve them in methylene chloride to form a 50g / L drug-carrier material composite The substance solution is transported to the mold sleeve by the peristaltic pump, and the ultrasonic driving power is turned on. Under the action of ultrasonic vibration, the solution sprays and disperses into droplets in the PVA aqueous solution through small holes, and ...

Embodiment 2

[0046] use figure 1 A device for preparing drug-containing microspheres, the effective height of the microsphere forming tube 4 is 200 cm, and the diameter of the small holes 302 is 100 μm;

[0047] First, the polyvinyl alcohol (PVA) aqueous solution with a concentration of 50 g / L is filled into the microsphere forming tube 4 and the microsphere solidifier 5, and the end of the nozzle 303 is inserted in the polyvinyl alcohol (PVA) aqueous solution;

[0048] Weigh 30g of aconitin (analgesic and anti-inflammatory drug) and 120g of PLGA, dissolve in ethyl acetate to form a 200g / L drug-carrier material complex solution, transport it to the mold sleeve by a peristaltic pump, turn on the ultrasonic drive power supply, Under the action of ultrasonic vibration, the solution is sprayed and dispersed into micro-droplets in the PVA aqueous solution through the small holes. At 55°C, the flow rate of 5L / min is continuously circulated for 300 minutes until the microspheres are initially sol...

Embodiment 3

[0054] use figure 1 A device for preparing drug-containing microspheres, the effective height of the microsphere forming tube 4 is 100 cm, and the aperture of the small hole 302 is 500 μm;

[0055] At first the hydroxypropyl methylcellulose (HPMC) aqueous solution that concentration is 2.5g / L is filled into microsphere forming tube 4 and microsphere solidifier 5, and the end of nozzle 303 is inserted in polyvinyl alcohol (PVA) aqueous solution middle;

[0056] Get 30g naltrexone (opioid receptor antagonist, used for drug rehabilitation, prevent relapse) and 70g PLA, dissolve in chloroform, form 300g / L drug-carrier material complex solution, deliver to stainless steel by peristaltic pump In the mold sleeve, turn on the ultrasonic driving power supply, and the solution is sprayed and dispersed into microdroplets in the HPMC aqueous solution through small holes under the action of ultrasonic vibration. Stir continuously at a stirring speed of 400r / min for 30min, and keep the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com