Neodymium ion doping soda-lime-silica based laser glass ceramics and preparation process thereof

A laser glass and soda-lime-silicon technology, applied in the field of transparent glass ceramic laser working material and its preparation, can solve the problems of high thermal conductivity gain of single crystal, poor thermal shock resistance, duplication of preparation process, etc. The effect of narrow line, low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] a kind of Na 2 O-CaO-SiO 2 It is 100g of raw materials for transparent laser glass ceramics. Measure 18.9% Na 2 O, 27.2% CaO, 47.9% SiO 2 , 2.5%TiO2+ZrO 2 , 0.5% Sb 2 o 3 , 2% NH 4 NO 3 , 1% Nd 2 o 3 .

[0013] Its preparation method:

[0014] (1) Glass melting: according to the above Nd 3+ Doped with Na 2 O-CaO-SiO 2 It is the component and content batching of transparent laser glass ceramic raw materials. After uniform mixing in a planetary ball mill for 3 hours, it is poured into a corundum crucible, melted in a silicon-molybdenum resistance furnace at 1450°C for 4 hours, poured into a preheated stainless steel mold, and melted. The body is rapidly cooled and solidified.

[0015] (2) Glass annealing: quickly place the formed glass body in a muffle furnace at 500°C for 2 hours, then cool down to room temperature with the furnace, and finally obtain a light purple transparent glass;

[0016] (3) Glass cutting: cutting the prepared glass products into sm...

Embodiment 2

[0021] Na 2 O-CaO-SiO 2 It is a transparent laser glass ceramic, raw material: 17.7% Na 2 O, 26.0% CaO, 46.3% SiO 2 , 4.5%TiO2+ZrO 2 , 0.5% Sb 2 o 3 , 2% NH 4 NO 3 , 3%Nd 2 o 3 .

[0022] Glass heat treatment: the sample was heat treated at 720°C for 6 hours to obtain transparent glass ceramics;

[0023] Others are with embodiment 1.

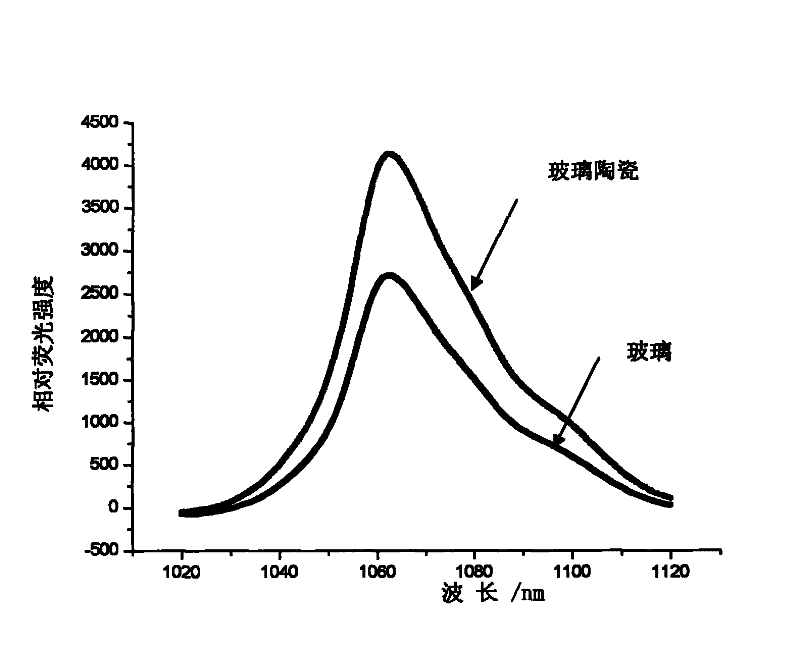

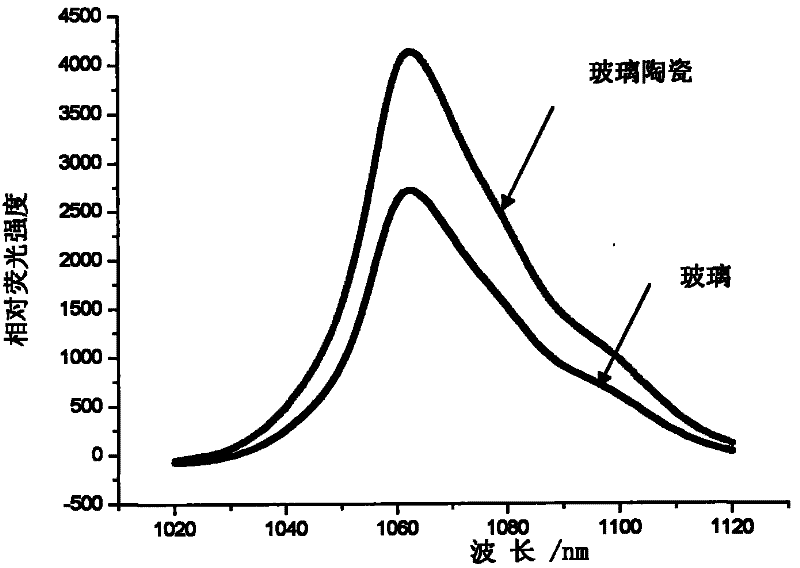

[0024] Performance measurement: Fluorescence intensity increased by 56%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com