Magnetic nano catalyst and preparation method thereof

A magnetic nano-catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of environmental pollution in the pharmaceutical industry, cumbersome process operations, high iron content in products, and expand application fields , the process is simple, the effect of improving the utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

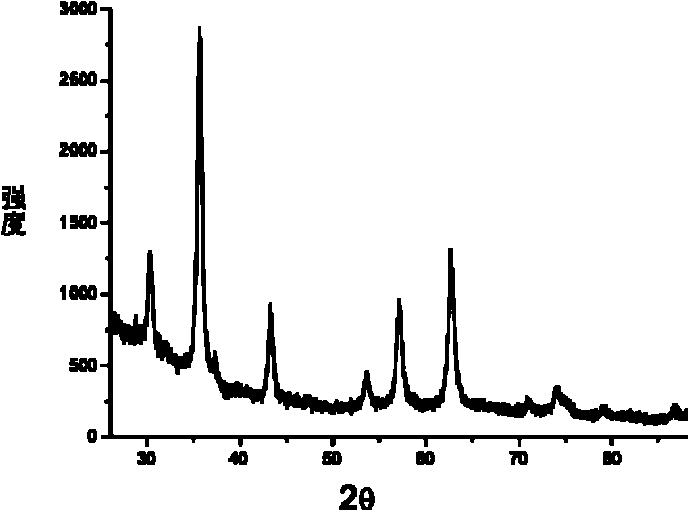

[0033] Example 1Pd-Fe 3 o 4 Loaded magnetic nano-catalyst is prepared through the following steps:

[0034] The first step, 0.0509mmol Na 2 PdCl 4 , 5.25mmol PVP (K30, molecular weight: 10000), 3.50mmolFe 3 Cl 6 ·6H 2 O, 35.0 mmol CH 3 COONa was sequentially added to 35ml of ethylene glycol.

[0035] In the second step, the above solution was stirred at room temperature until a uniform suspension was formed, and then the suspension was transferred to a stainless steel reactor with a 50ml polytetrafluoroethylene liner, and allowed to react naturally at 200°C for 8 hours. Cool to room temperature.

[0036] The third step is to settle and separate the brown-black product of Dedao under the action of an external magnetic field, and redisperse it in a mixed solution of ethanol and water for cleaning, so that the sedimentation and separation-cleaning cycle is 2-3 times, and some ions and excess on the surface are removed. The polymer and other impurities are washed away; th...

Embodiment 2

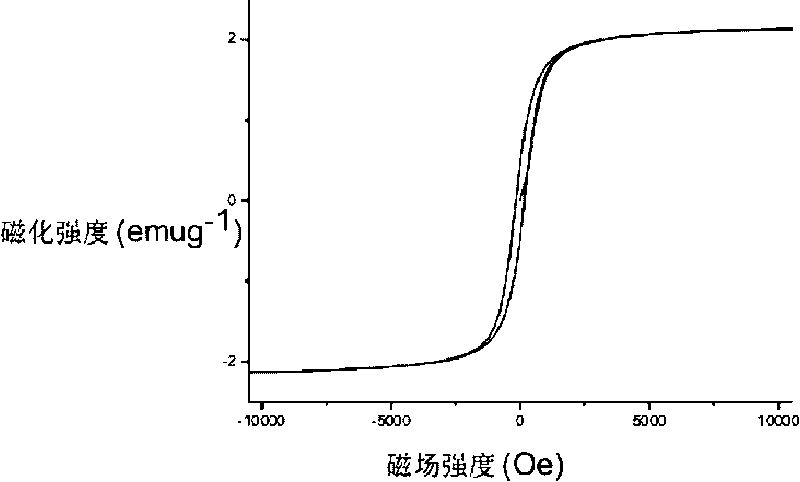

[0050] Similar to the steps of Example 1, the difference is that in Example 2 Na 2 PdCl 4 The dosage is 0.127mmol. Get Pd-Fe 3 o 4 Supported magnetic nano catalyst particles, the content of Pd is 4.69wt%, the average particle size is 96nm, and the catalytic reaction rate constant is 0.72mmol -1 the s -1 .

Embodiment 3

[0052] Similar to the steps of Example 1, the difference is that Na in Example 3 2 PdCl 4 The dosage is 0.254mmol. Get Pd-Fe 3 o 4 Supported magnetic nano catalyst particles, the content of Pd is 8.14wt%, the average particle size is 10nm, and the catalytic reaction rate constant is 2.3mmol -1 the s -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com