Temperature resistant quaternary ammonium type anion exchange resin phase transfer catalyst and preparation method thereof

A phase transfer catalyst, exchange resin technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. Separation and other problems to achieve the effect of reducing organic content, simple synthesis process and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

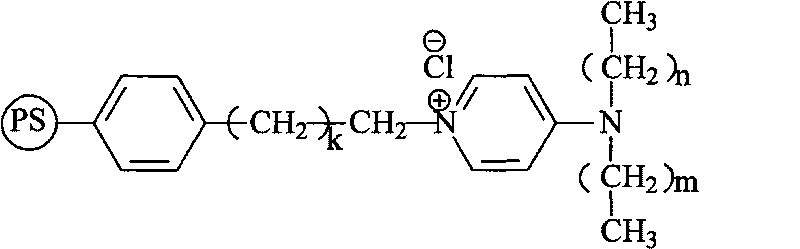

[0025] In a 100mL four-neck flask equipped with an electric stirrer, a spherical condenser, and a thermometer, add 10.5g of chloromethylated chlorine balls (chlorine content 25.4%, 0.075mol chlorine), then add 60.0mL of dichloromethane to swell for 2 hours, and then Add 28.1g (0.23mol) of 4-dimethylaminopyridine (mass ratio with chlorine balls: 3:1), stir at 40°C for 30h, after the reaction is over, place the resin in a glass ion exchange column, and use Rinse with ethanol until no oil flows out, and then rinse with deionized water. Obtained 4-dimethylaminopyridinium salt strong basic anion exchange resin, exchange capacity: 3.11mmol / g. The structure is:

[0026]

Embodiment 2

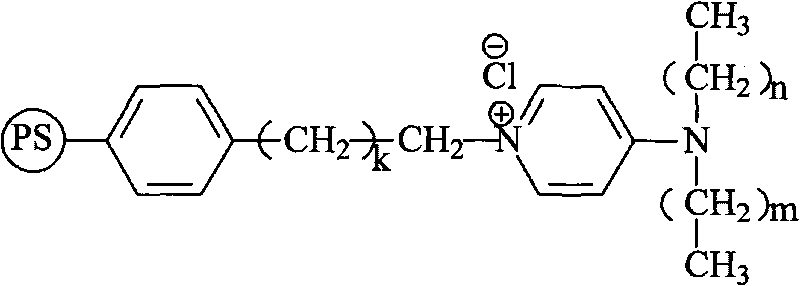

[0028] In a 100mL four-necked flask equipped with an electric stirrer, a spherical condenser, and a thermometer, add 9.5g of chloroethyl chloride balls (chlorine content 24.5%, 0.066mol chlorine), then add 60.0mL tetrahydrofuran to swell for 2 hours, and then add 19.8 g (0.13mol) 4-diethylaminopyridine (mass ratio to chlorine balls is 2:1), stirred at 60°C for 20h, after the reaction, put the resin in a glass ion exchange column, rinse with ethanol Rinse with deionized water until no oil flows out. Obtained 4-diethylaminopyridinium salt strongly basic anion exchange resin with an exchange capacity of 3.17 mmol / g. The structure is:

[0029]

Embodiment 3

[0031] In a 100mL four-neck flask equipped with an electric stirrer, a spherical condenser, and a thermometer, add 13.6g of chloropropyl chloride balls (chlorine content 22.8%, 0.087mol chlorine), and then add 60.0mL of N,N-dimethyl Formamide was swollen for 2 hours, and then 11.9 g (0.087 mol) of 4-(N-methyl-N-ethyl)-aminopyridine (mass ratio to chlorine balls: 1:1) was added, and stirred at 100°C for 10 hours, After the reaction, the resin was placed in a glass ion-exchange column, rinsed with ethanol until no oil flowed out, and then rinsed with deionized water. 4-(N-methyl-N-ethyl)-aminopyridinium salt strong basic anion exchange resin was obtained, with an exchange capacity of 3.25 mmol / g. The structure is:

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com