Method for reducing alkyne into cis-form olefin

A technology of cis-alkene and alkyne, applied in the field of catalytic synthesis of fine chemical products, can solve the problems of limited substrate universality, long time requirement, high alkyne yield, and achieve high chemical reaction and stereoselectivity, Efficient reduction reaction and simple reaction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh respectively 42.0 mg (0.75 mmol) of potassium hydroxide, 89.0 mg (0.5 mmol) of toluene acetylene, and Pd(OAc) 2 2.3 mg (0.01 mmol), was added to a 25-mL glass reaction tube with a cover, the air in the reaction tube was replaced with nitrogen, 1 mL of DMF was added under a nitrogen atmosphere, then the reaction tube was sealed, and the reaction tube was placed in an oil bath and heated to 145°C, stirred and kept warm for 6 hours, then cooled to room temperature. Reaction result: the isolated target product cis-stilbene was weighed, and the isolated yield of the product was calculated to be 97%.

Embodiment 2

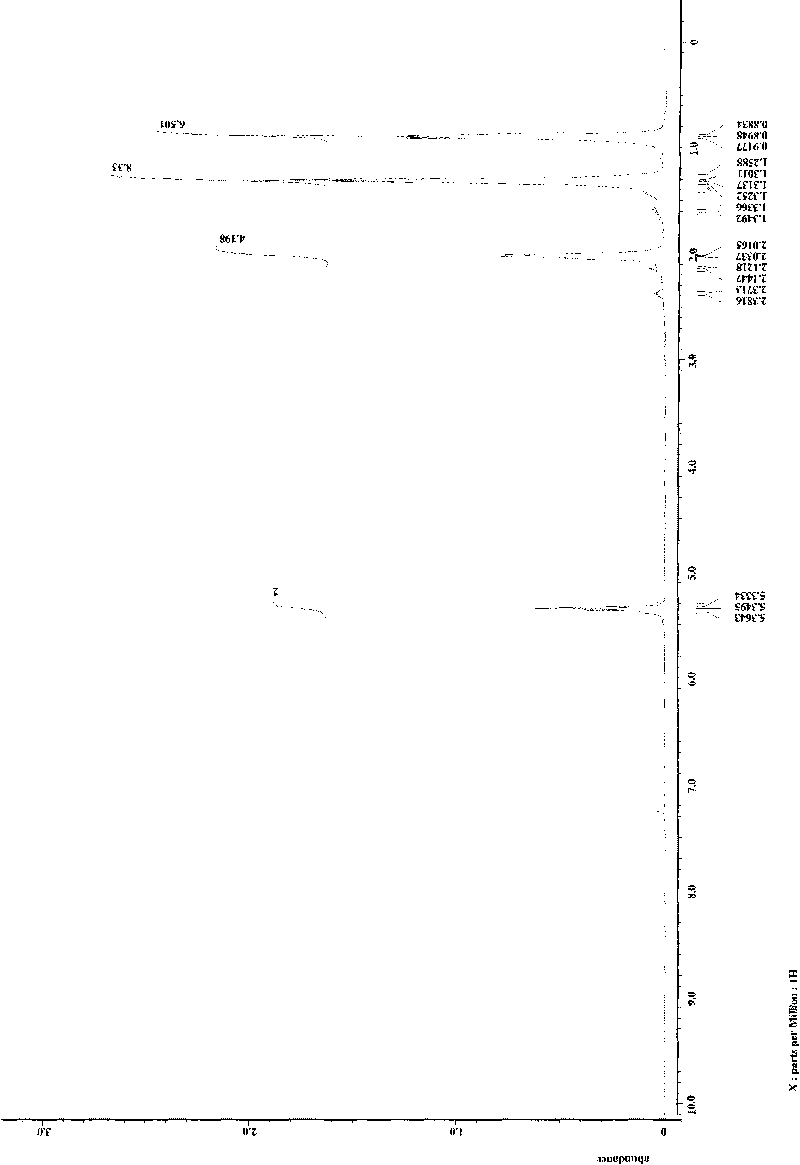

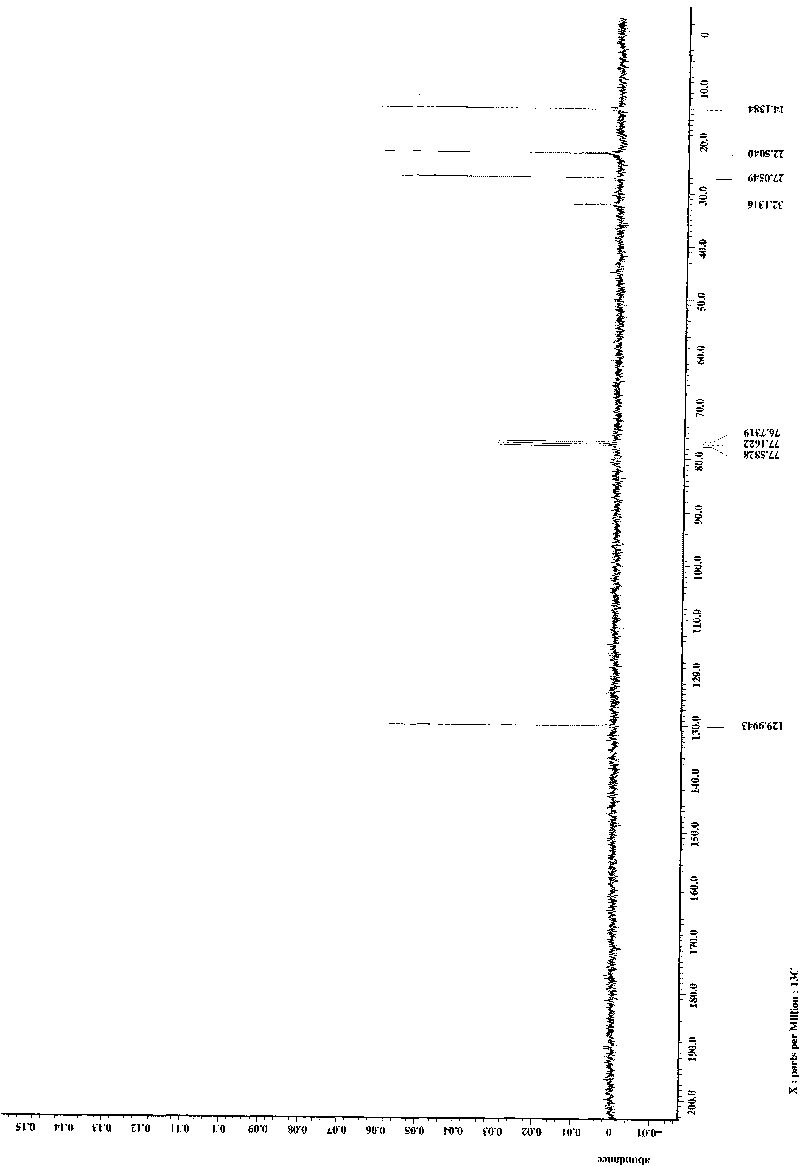

[0036] Weigh respectively 42.0mg (0.75mmol) of potassium hydroxide, 69.0mg (0.5mmol) of 5-decyne, and Pd(OAc) 2 , 2.3 mg (0.01 mmol), was added to a 25-mL glass reaction tube with a cover, the air in the reaction tube was replaced with nitrogen, 1 mL of DMF was added under a nitrogen atmosphere, then the reaction tube was sealed, and the reaction tube was heated in an oil bath to 145°C, stirred and kept warm for 6 hours, then cooled to room temperature. Reaction result: the isolated target product cis-5-decene was weighed, and the isolated yield of the product was calculated to be 87%. figure 1 , figure 2 They are the hydrogen spectrum and carbon spectrum of the target product cis-5-decene obtained in this example, respectively. It can be seen from the figure that the structure of the product is correct.

Embodiment 3

[0038] Weigh respectively 42.0 mg (0.75 mmol) of potassium hydroxide, 79.0 mg (0.5 mmol) of 1-phenyl-1-hexyne, and Pd(OAc) 2 2.3 mg (0.01 mmol), was added to a 25-mL glass reaction tube with a cover, the air in the reaction tube was replaced with nitrogen, 1 mL of DMF was added under a nitrogen atmosphere, then the reaction tube was sealed, and the reaction tube was placed in an oil bath and heated to 145°C, stirred and kept warm for 6 hours, then cooled to room temperature. Reaction result: the isolated target product cis-1-phenyl-1-hexene was weighed, and the isolated yield of the product was calculated to be 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com