Method for preparing beta-type lead dioxide nanometer particles

A nanoparticle and lead dioxide technology, applied in the field of nanomaterials, can solve the problem that the particle size and morphology of lead dioxide nanopowders cannot be controlled, are not suitable for large-scale industrial applications, and lead dioxide nanoparticles are rare, etc. problems, to achieve high conversion efficiency and catalytic activity, wide industrial use, controllable particle size and morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

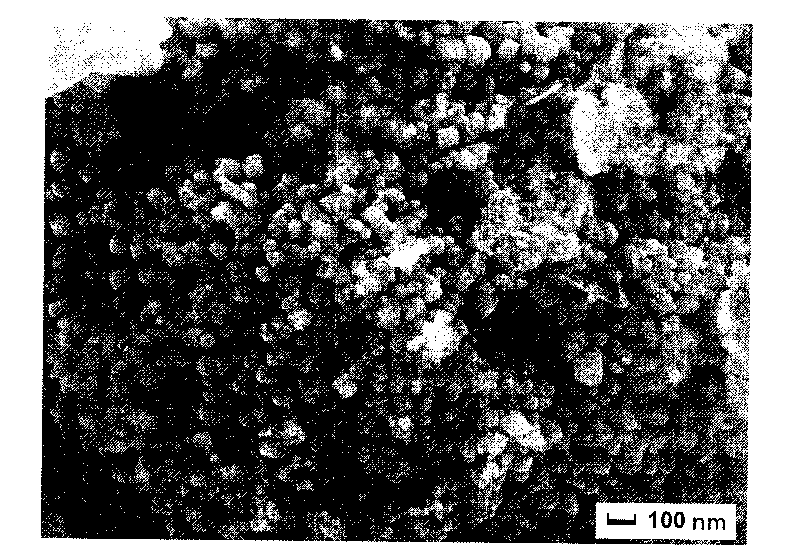

[0018] Dissolve 0.4979g of lead nitrate in 50ml of 1M sodium hydroxide solution, add 0.3g of sodium dodecylbenzenesulfonate and 0.5406g of sodium persulfate successively under stirring, and react in a water bath at 80°C in a closed reaction kettle for 6 hours, after cooling to room temperature, centrifuge the above reaction product at a speed of 1500r / min for 10 minutes, separate the obtained solid, rinse it with a large amount of ethanol aqueous solution for 3 times, and dry it in vacuum at 50°C for 2 hours, and the obtained powder is lead dioxide nanoparticles.

[0019] The product of this embodiment is scanned by electron microscope to observe its microscopic appearance, and the obtained SEM pictures are as follows: figure 1 shown.

Embodiment 2

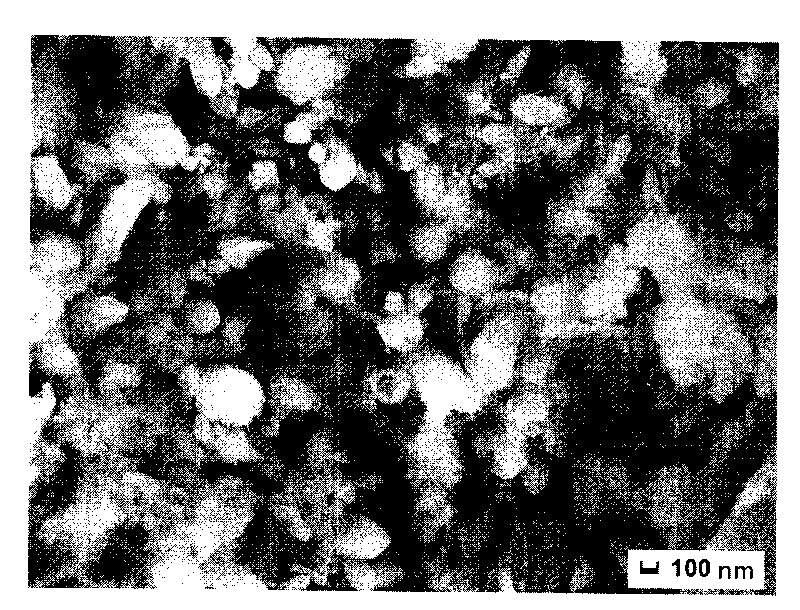

[0021] Dissolve 0.4979g of lead nitrate in 50ml of 1M sodium hydroxide solution, add 0.15g of polyethylene glycol and 0.5406g of potassium persulfate successively under stirring, react in a water bath at 130°C for 18 hours in a closed reactor, and cool to room temperature Finally, the above reaction product was centrifuged at 1500r / min for 10 minutes to separate the obtained solid, rinsed three times with a large amount of ethanol aqueous solution, and dried in vacuum at 50°C for 2 hours, and the obtained powder was lead dioxide nanoparticles.

[0022] The product of this embodiment is scanned by electron microscope to observe its microscopic appearance, and the obtained SEM pictures are as follows: figure 2 shown.

Embodiment 3

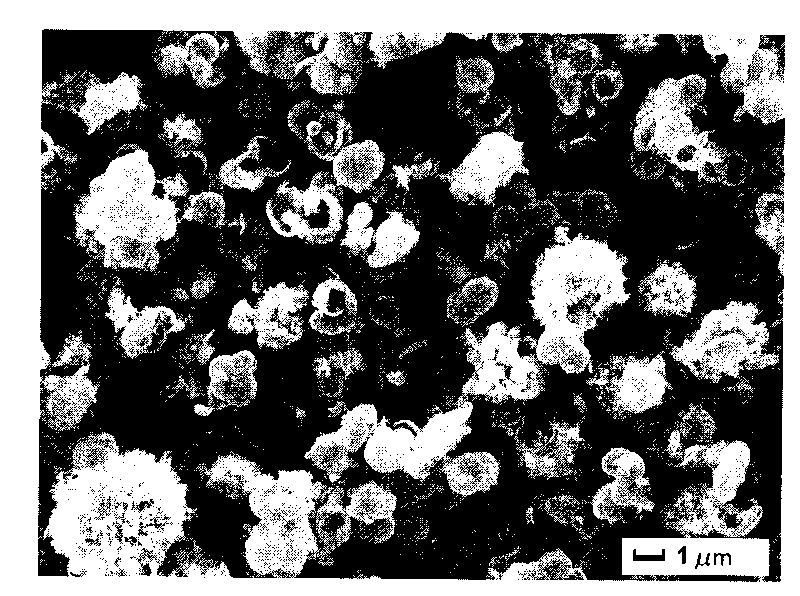

[0024] Dissolve 0.2650g of lead nitrate in 40ml of 1M sodium hydroxide solution, add 0.02g of polyvinylpyrrolidone and 0.3651g of ammonium persulfate successively under stirring, react in a water bath at 180°C for 24 hours in a closed reactor, and cool to room temperature Finally, the above reaction product was centrifuged at 1500r / min for 10 minutes to separate the obtained solid, rinsed three times with a large amount of ethanol aqueous solution, and dried in vacuum at 50°C for 2 hours, and the obtained powder was lead dioxide nanoparticles.

[0025] The product of this embodiment is scanned by electron microscope to observe its microscopic appearance, and the obtained SEM pictures are as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com