Biological detoxification method and detoxification active bacterial strain of hemicellulose hydrolysate

A hydrolyzate and semi-fiber technology, applied in the biological field, can solve the problems of cumbersome process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

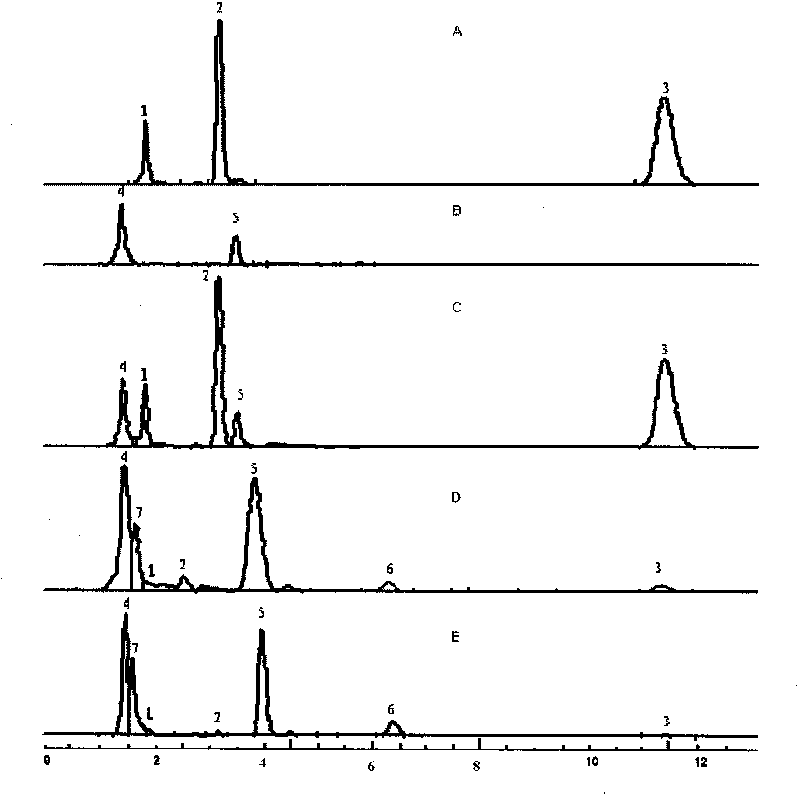

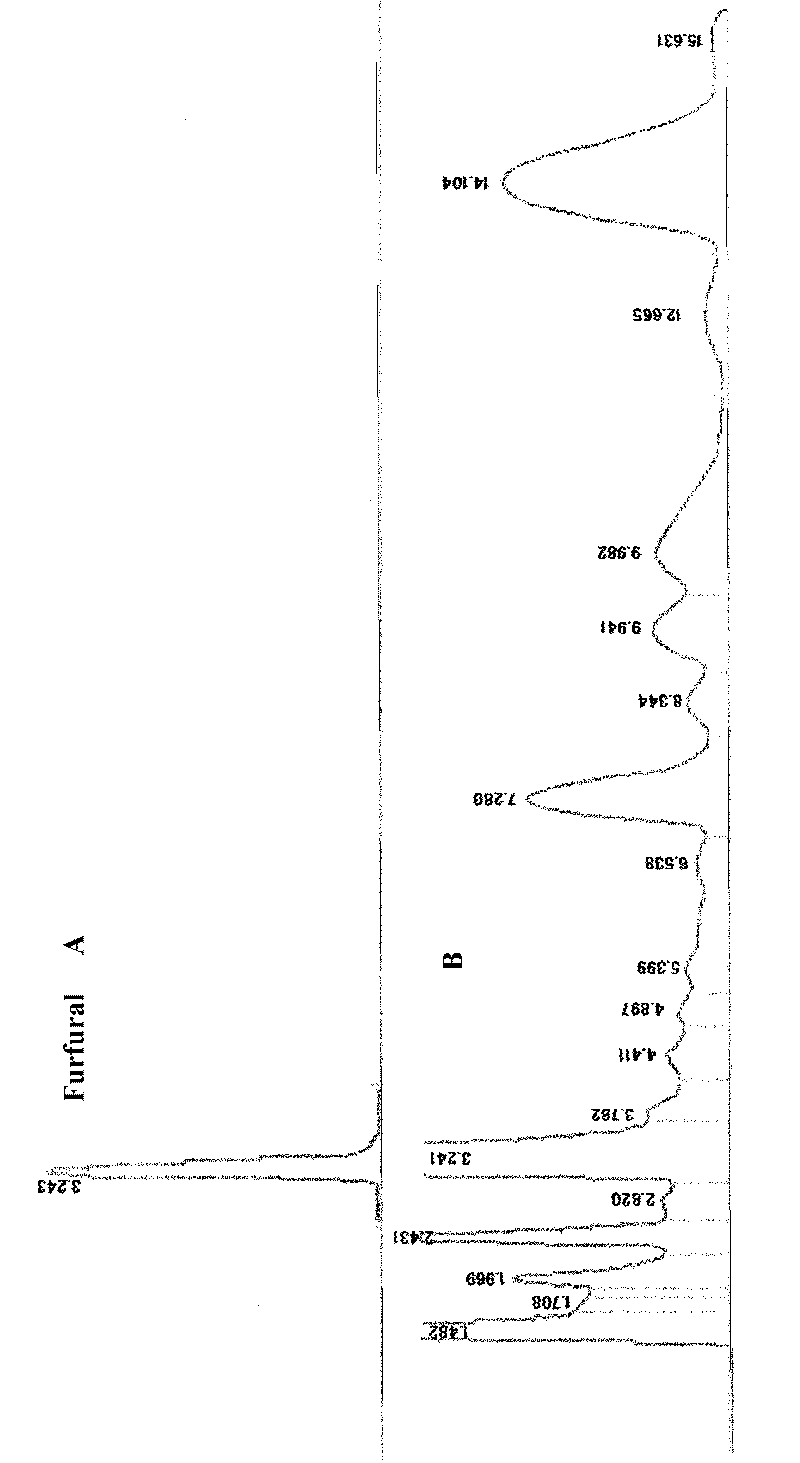

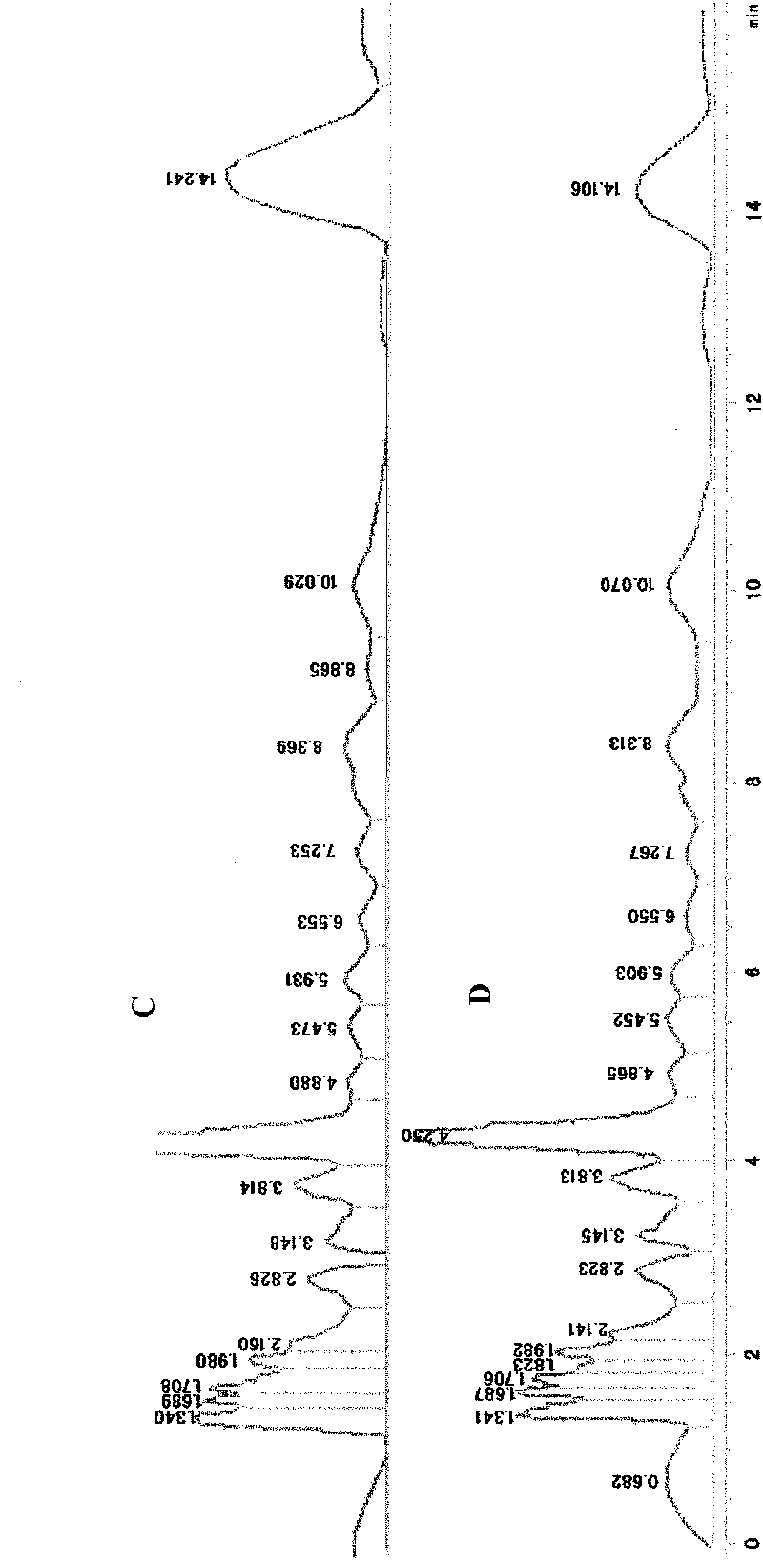

Image

Examples

Embodiment 1

[0080] Weigh 3kg of bagasse that has been washed and re-dried, add H2SO4 solution (2.5%, w / w) according to the solid-to-liquid ratio (w / v) of 1:7, hydrolyze for 2h at 120°C, collect the filtrate by centrifugation, wash the filter residue once, and combine The filtrate was adjusted to pH 3 with solid calcium carbonate, and the precipitate was removed by suction filtration to obtain bagasse hemicellulose hydrolyzate. The reducing sugar content of the hydrolyzate is 3%, and xylose monosaccharide accounts for more than 80% of the total sugar.

Embodiment 2

[0082] Take 2 kg of crushed dry corncobs, add 2% (w / w) H at a solid-to-liquid ratio of 1:7 2 SO 4 The solution was hydrolyzed at 120°C for 2 hours, the liquid part was collected, neutralized with calcium carbonate to a pH value of 3, and the precipitate was removed by suction filtration to obtain a dilute acid hydrolyzate of corncob hemicellulose. The total sugar content of the hydrolyzate is 5%, wherein xylose accounts for about 60% of the total sugar.

Embodiment 3

[0084] Inoculate the slant of I. orientalis CCTCC NO: M206098 on the liquid seed medium, culture at 200rmp, 30°C on a shaker for 12h, and obtain the activated seed liquid. Insert the inoculum amount of 15% (v / v) into Example 1, in the dilute acid hydrolyzate of bagasse hemicellulose obtained, 200rmp, 33 ℃ of shaking table fermentation detoxification 45h, centrifuge supernatant is the product obtained by Oriental Yisa Yeast CCTCC NO: M206098 Bio-detoxified bagasse hemihydrolyzate.

[0085] Under the same conditions, the bagasse hemicellulose hydrolyzate in Example 1 was treated with I. westernis CCTCC NO: M206097 to obtain the bagasse hemicellulose hydrolyzate biodetoxified by I. westernia CCTCC NO: M206097.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com