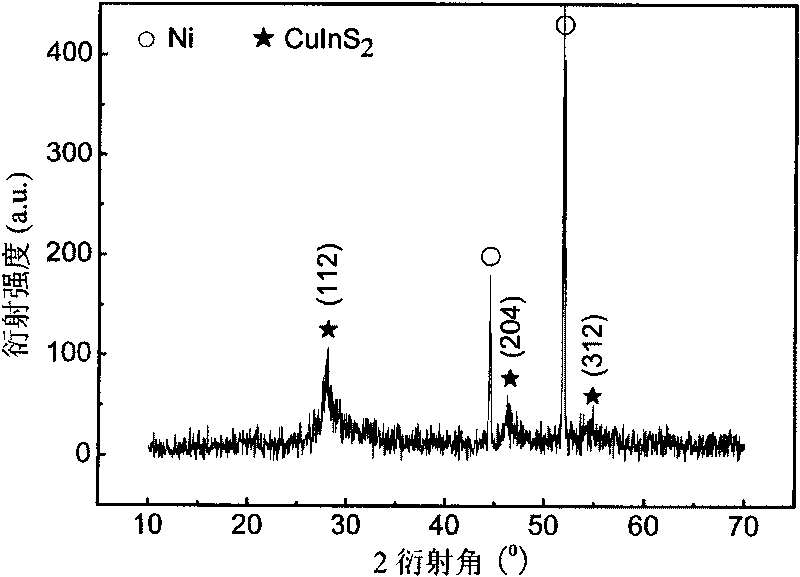

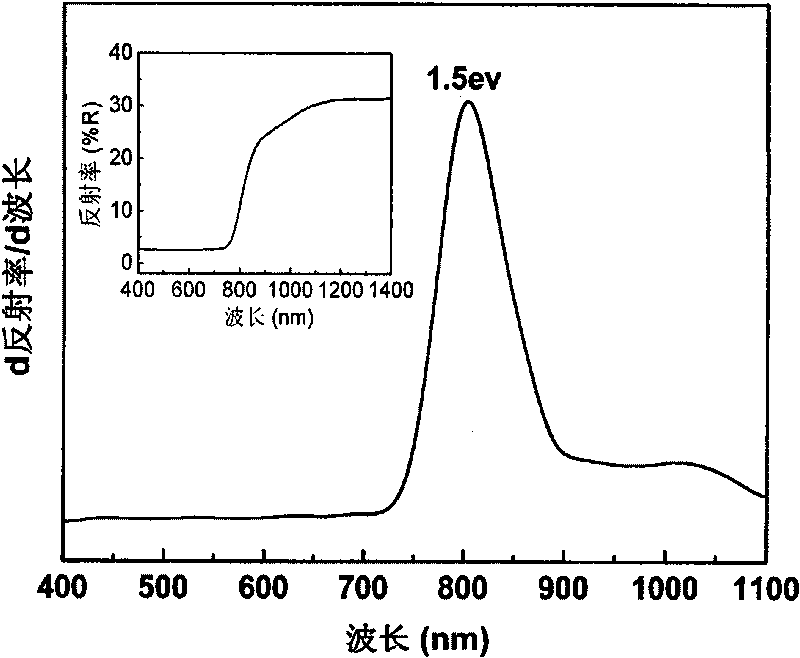

Preparation method of CuInS2 nanometer crystal semiconductor film

A semiconductor and nanocrystalline technology, which is applied in the field of preparation of CuInS2 nanocrystalline semiconductor thin films, can solve problems such as white turbidity, reduced stability, and poor stability of electrodeposition liquid systems, and achieve uniform and stable growth, precise control of film thickness, and enhanced reliability. The effect of controllability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

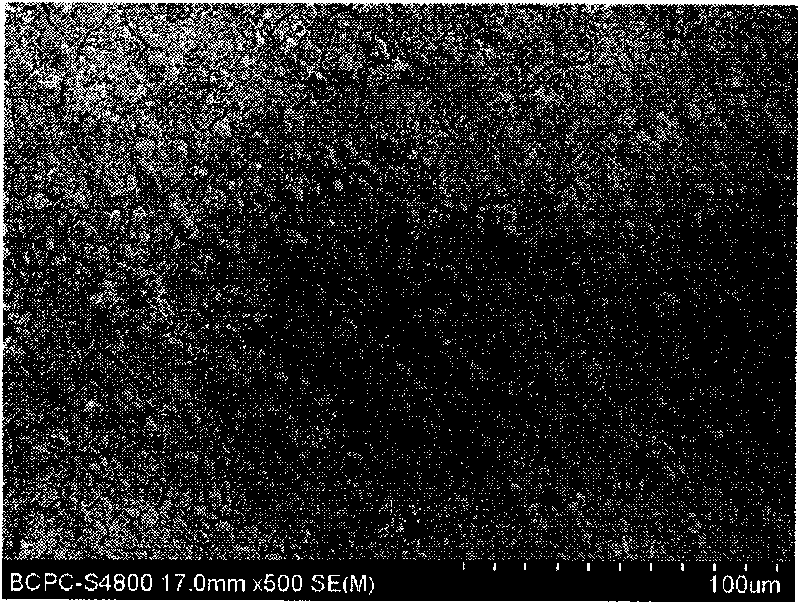

Embodiment 1

[0021] 1) Weigh 0.704gC in turn 8 h 5 KO 4 , 0.32gCuCl 2 2H 2 O, 0.44gInCl 3 4H 2 O, 1.49gNa2 S 2 o 3 ·5H 2 O, 0.90g LiCl·H 2 O was dissolved in 150ml deionized water (the reagents used were all analytically pure, and the molar ratio was 2.3:1.25:1:4:10), and the pH of the solution was adjusted to 2.5 with 1mol / l hydrochloric acid, and stirred evenly;

[0022] 2) The solution prepared in step 1) is used as the electrodeposition solution, the pretreated nickel foil is used as the working electrode, the platinum sheet is used as the auxiliary electrode, and saturated calomel is used as the reference electrode, and the three are connected to a constant current electrode with a wire. On the working electrode, auxiliary electrode and reference electrode terminal button of the potentiometer, ensure that the distance between the nickel foil and the platinum sheet is 5cm, and use the temperature control device to control the temperature of the electrodeposition solution at 30...

Embodiment 2

[0026] 1) Weigh 1.056gC in turn 8 h 5 KO 4 , 0.48gCuCl 2 2H 2 O, 0.66gInCl 3 4H 2 O, 2.235gNa 2 S 2 o 3 ·5H 2 O, 1.35g LiCl·H 2 O was dissolved in 200ml of deionized water (the reagents used were all analytically pure, and the molar ratio was 2.3:1.25:1:4:10), and the pH of the solution was adjusted to 2.0 with 1mol / 1 hydrochloric acid, and stirred evenly;

[0027] 2) With the solution prepared in step 1) as the electrodeposition solution, with the pretreated ITO conductive glass as the working electrode, with the platinum sheet as the auxiliary electrode, with saturated calomel as the reference electrode, and connect the three to the On the working electrode, auxiliary electrode and reference electrode terminal buttons of the potentiostat, ensure that the distance between the nickel foil and the platinum sheet is 5cm, and use the temperature control device to control the temperature of the electrodeposition solution at 20±1°C and the potential at -0.95 V(vs.SCE), p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Bandgap | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com