Preparation method of metal bipolar plate surface coating of proton exchange membrane fuel cell

A technology of metal bipolar plates and proton exchange membranes, which is applied to fuel cell parts, battery electrodes, circuits, etc., can solve the problems of no explanation or report, no data collected, etc., and achieve low cost and high corrosion resistance performance and low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

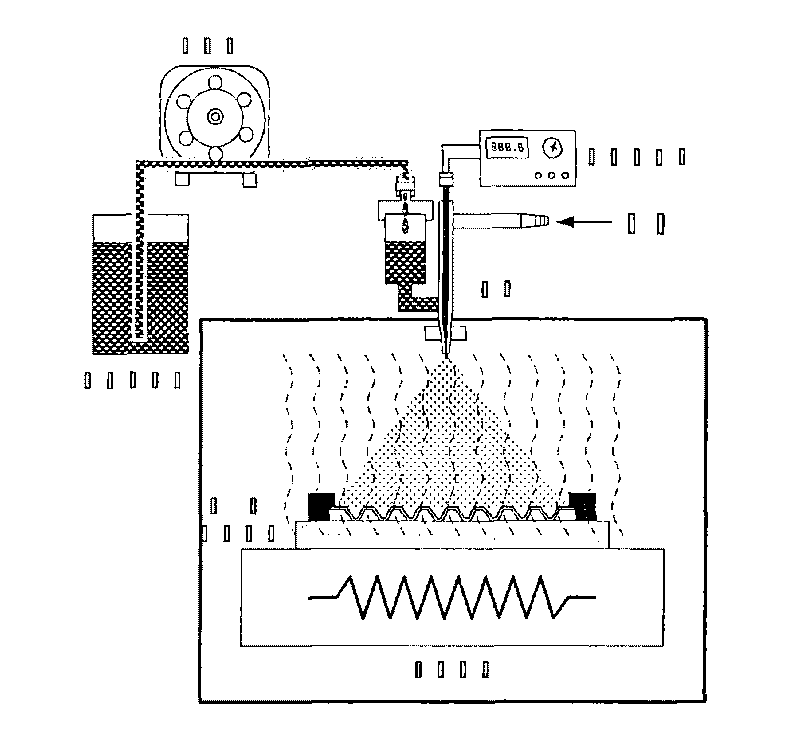

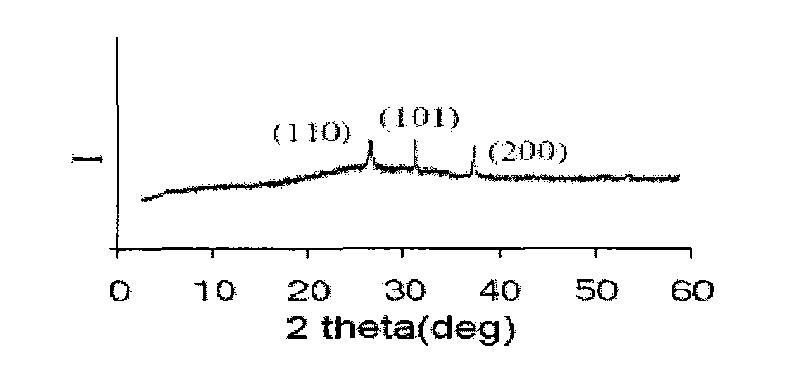

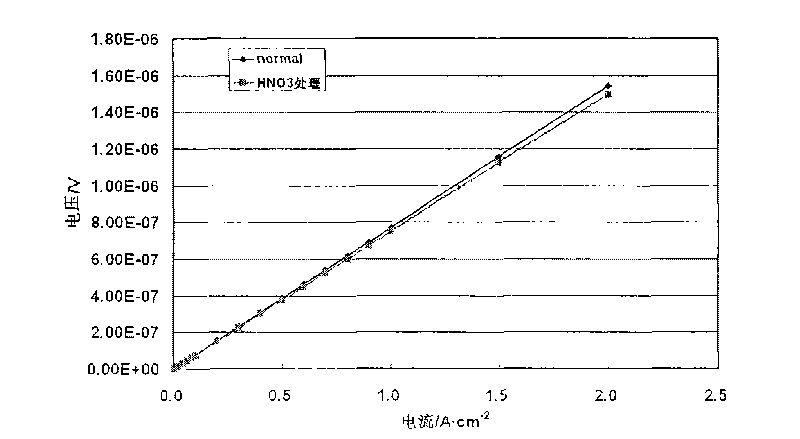

[0048] Preparation of SnO by Spray Pyrolysis 2 :F conductive coating (FTO), because this method has the lowest cost compared with other methods.

[0049] Its specific implementation method comprises the following steps:

[0050] 1) Preparation of coating solution;

[0051] SnCl 2 ·xH 2 O. Hydrofluoric acid or ammonium fluoride, methanol or ethanol or isopropanol, deionized water, and hydrochloric acid are formulated into a coating solution according to the ratio in Table 2, and stirred at 70-90°C for 10-20 minutes.

[0052] Table 2

[0053]

[0054] SnCl 2 ·xH 2 O is used to make SnO 2 Coating precursor solution, hydrofluoric acid (concentration 40%) is used as doping material, and water in solution provides oxygen for chemical reaction. In addition, a little HCl (concentration 36%) can be added to improve the SnCl 2 Solubility of the solution. Considering the composition of the coating, the SnCl in the precursor solution 2 :HF=1:1.0-1.2 is more preferable. In a...

Embodiment 2

[0063] Preparation of SnO by Spray Pyrolysis 2 : (F+Sb) conductive coating, the method comprises the steps:

[0064] 1) Preparation of coating solution;

[0065] SnCl 2 2H 2 O was mixed with absolute ethanol or methanol or isopropanol and deionized water in a molar ratio of 1:20:20, stirred at 60-80°C until clear, then added the ethanol solution of SbCl3 and trifluoroacetic acid, and continued to stir for 2h, A transparent and clear sol was obtained. The doping amounts of Sb and F are respectively 0-5% and 40-60% (molar ratio).

[0066] 2) The preparation of the metal bipolar plate is the same as step 2) of Example 1.

[0067] 3) The process of spraying, pyrolytic conductive coating preparation and post-treatment is the same as step 3) of embodiment 1.

Embodiment 3

[0069] Preparation of SnO by Sputtering 2 :F conductive coating (FTO). Although the cost of this method is higher than the spray pyrolysis method, it has certain technical advantages in the preparation of large-scale samples and mass production. The method comprises the steps of:

[0070] 1) Preparation of coating solution

[0071] The sputtering target source can use x%Sn-(100-x-y)%SnF 2 -y%MO, x%SnO can also be used 2 -(100-x-y)%SnF 2 -y%MO. Determine the values of x and y in the target source through experiments to obtain the coating with the element content in Table 1. Target source preparation further includes the following steps:

[0072] ①Sn-SnF 2 -MO target source preparation

[0073] Metal Sn powder, SnF 2 After co-melting with other dopant powder at 240°C, pour it into the mold to make x%Sn-(100-x-y)%SnF 2 -y% MO target source.

[0074] ②SnO 2 -SnF 2 -MO target source preparation, including the following methods:

[0075] Method 1: Add x%SnO 2 -(100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com