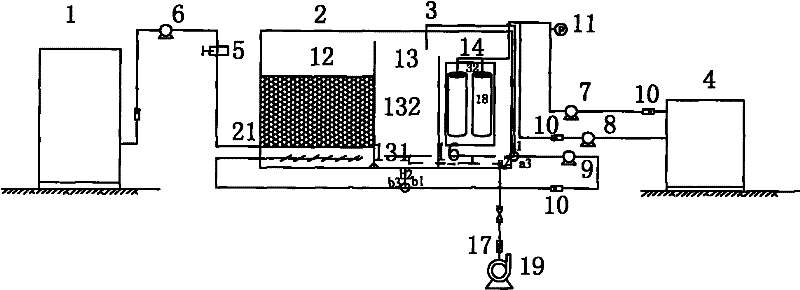

Biological filter-ceramic membrane biological reactor device and water purifying application method thereof

A membrane bioreactor and bioreactor technology, applied in the field of environmental engineering, can solve the problems of low COD and ammonia nitrogen removal rate, pollution, membrane fouling, etc., and achieve high aerobic microbial concentration, flexible operating conditions, and controllable operating conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

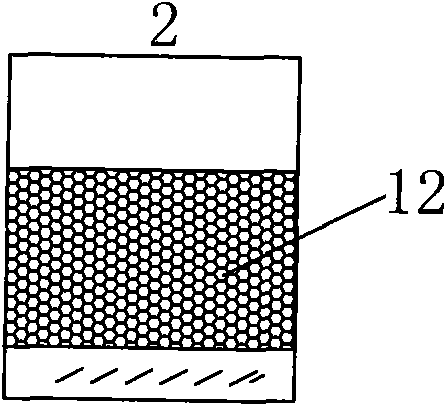

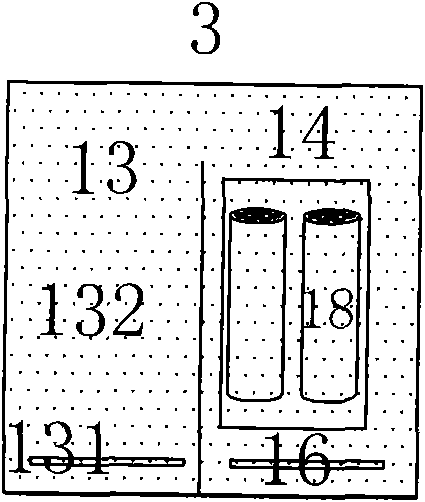

Embodiment 1

[0044] The raw water is polluted river water from an experimental river section in Beijing, which is treated with the above-mentioned device, and the hydraulic load is 40m 3 / m 2 d. Raw water enters the anaerobic biological filter unit from the lower end of the pool body, flows through the polyurethane filler to the upper end of the pool body, and undergoes biochemical reactions under anaerobic conditions. The dissolved oxygen concentration is controlled at 0.5-2mg / L, and the hydraulic retention time is 3h. The buffer reagent controls the pH value to be 6-8, the temperature is 24-28°C, and the wet density of the filler is 0.8g / cm 3 , the water holding capacity is 2400%, and the specific surface area is 100m 2 / g; the effluent from the anaerobic biofilter flows in from the upper end of the biological unit of the aerobic membrane bioreactor to carry out the biochemical reaction of aerobic microorganisms, and is aerated through the perforated tube. The oxygen concentration is ...

Embodiment 2

[0047] The raw water is heavily polluted river water from an experimental river section in Beijing, which is treated with the above-mentioned device, and the hydraulic load is 25m 3 / m 2 d. Raw water enters the anaerobic biological filter unit from the lower end of the pool body, flows through the polyurethane filler to the upper end of the pool body, and undergoes biochemical reactions under anaerobic conditions. The dissolved oxygen concentration is controlled at 0.5-2mg / L, and the hydraulic retention time is 3h. The buffer reagent controls the pH value to be 6-8, the temperature is 20-28°C, and the wet density of the filler is 0.8g / cm 3 , the water holding capacity is 2400%, and the specific surface area is 100m 2 / g; the effluent from the anaerobic biofilter flows in from the upper end of the biological unit of the aerobic membrane bioreactor to carry out the biochemical reaction of aerobic microorganisms, and is aerated through the perforated tube. The dissolved oxygen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com