Polybutylene terephthalate/polyphenylether composite material

A polybutylene terephthalate and composite material technology, which is applied in the field of polybutylene terephthalate/polyphenylene ether composite materials, can solve the problems of high cost and unsatisfactory compatibility, and achieves Overcome the effects of poor compatibility, excellent processability and mechanical properties, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

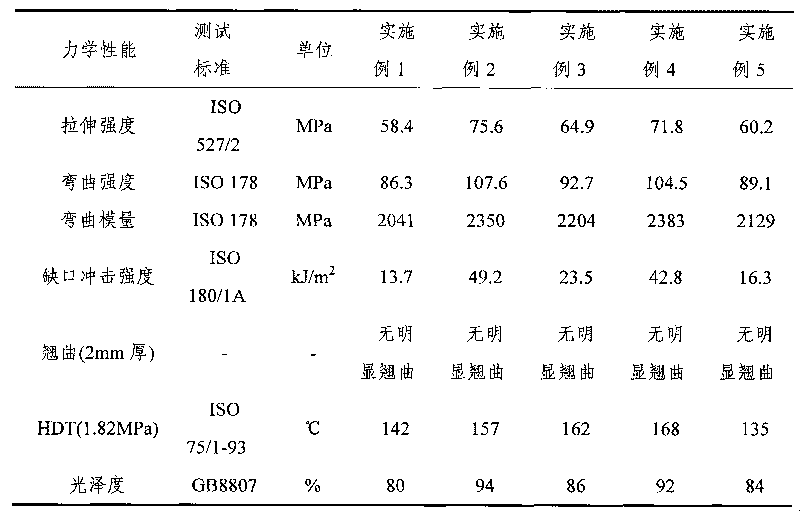

Examples

Embodiment 1

[0043] (1) Preparation of compatibilizer

[0044] 30 parts by weight of polar copolymer A, 70 parts by weight of polar copolymer B, 2 parts by weight of active monomer and 0.2 parts by weight of initiator are reacted and extruded, and the extrusion temperature is 200 ° C; wherein: polar copolymer A By 10 parts by weight of styrene-acrylonitrile-glycidyl methacrylate copolymer, 10 parts by weight of ethylene-glycidyl methacrylate copolymer and 10 parts by weight of ethylene-n-butyl acrylate-glycidyl methacrylate Copolymer composition; Polar copolymer B is made up of 30 parts by weight of EPDM grafted polystyrene and 40 parts by weight of high impact polystyrene (trademark is HIPS MA5210, produced by Chevron Phillips); The active monomer consists of 1 part by weight of maleic acid and 1 part by weight of maleic anhydride glycine acrylate; ) Benzene peroxyester composition.

[0045] (2) Preparation of polybutylene terephthalate / polyphenylene ether composites

[0046] First, 10...

Embodiment 2

[0049] (1) Preparation of compatibilizer

[0050] 70 parts by weight of polar copolymer A, 30 parts by weight of polar copolymer B, 5 parts by weight of active monomer and 1 part by weight of initiator are reacted and extruded, and the extrusion temperature is 180 ° C; wherein: polar copolymer A Copolymerized by 20 parts by weight of styrene-acrylonitrile-glycidyl methacrylate copolymer, 20 parts by weight of styrene-glycidyl methacrylate and 30 parts by weight of ethylene-n-butyl acrylate-glycidyl methacrylate composition; polar copolymer B consists of 10 parts by weight of polystyrene (the trade mark is PS GPPS 251P, Shanghai Secco Petrochemical Co., Ltd.) and 20 parts by weight of a copolymer of polystyrene and butadiene; the active monomer It consists of 3 parts by weight of maleic acid and 2 parts by weight of ethylene glycol dimethacrylate; the initiator consists of 0.5 parts by weight of diacyl peroxide and 0.5 part by weight of alkyl aralkyl peroxide.

[0051] (2) Pre...

Embodiment 3

[0055] (1) Preparation of compatibilizer

[0056] 50 parts by weight of polar copolymer A, 50 parts by weight of polar copolymer B, 4 parts by weight of active monomer and 0.5 part by weight of initiator are reacted and extruded, and the extrusion temperature is 190 ° C; wherein: polar copolymer A Consists of 25 parts by weight of styrene-acrylonitrile-glycidyl methacrylate copolymer and 25 parts by weight of ethylene-glycidyl methacrylate copolymer; polar copolymer B consists of 25 parts by weight of high-impact polystyrene (the trade mark is HIPS MA5210, Chevron Phillips chemical) and 25 parts by weight acrylonitrile-butadiene-styrene copolymer composition; Active monomer is made up of 2 weight parts acrylic acid and 2 weight parts diallyl terephthalate Composition: The initiator consists of 0.2 parts by weight of alkylaralkyl peroxide and 0.3 parts by weight of bis(tert-butylperoxyisopropyl)benzene peroxide.

[0057] (2) Preparation of polybutylene terephthalate / polyphenyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com