Graphene/silicon carbide Schottky junction based photovoltaic cell and preparation method thereof

A photovoltaic cell and Schottky junction technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of inability to synthesize the macroscopic structure of photovoltaic performance carbon nanotubes, inability to precisely control the chirality of carbon tubes, and large voids in the network structure. , to achieve the effect of suitable for large-scale application, excellent light transmission and conductivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

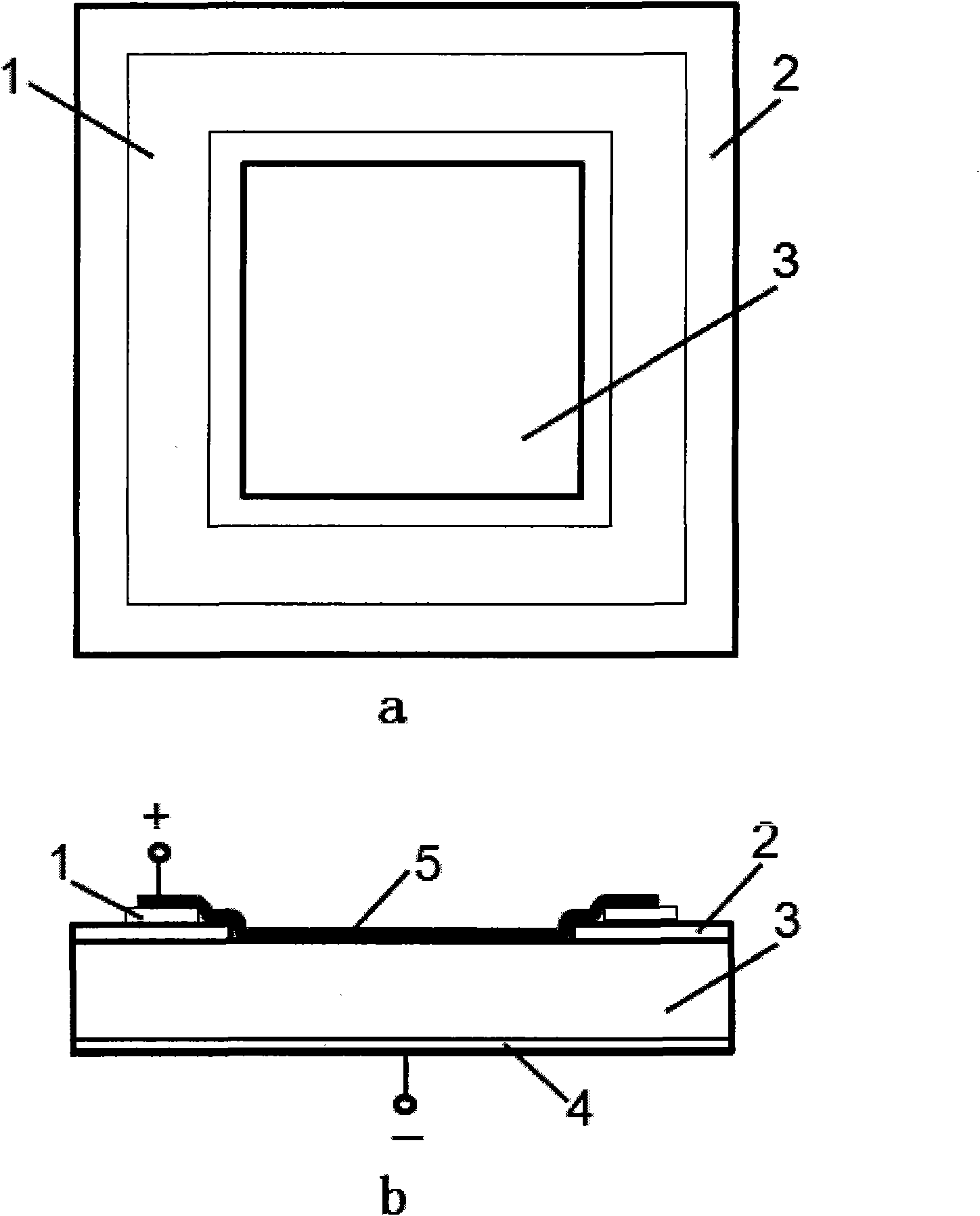

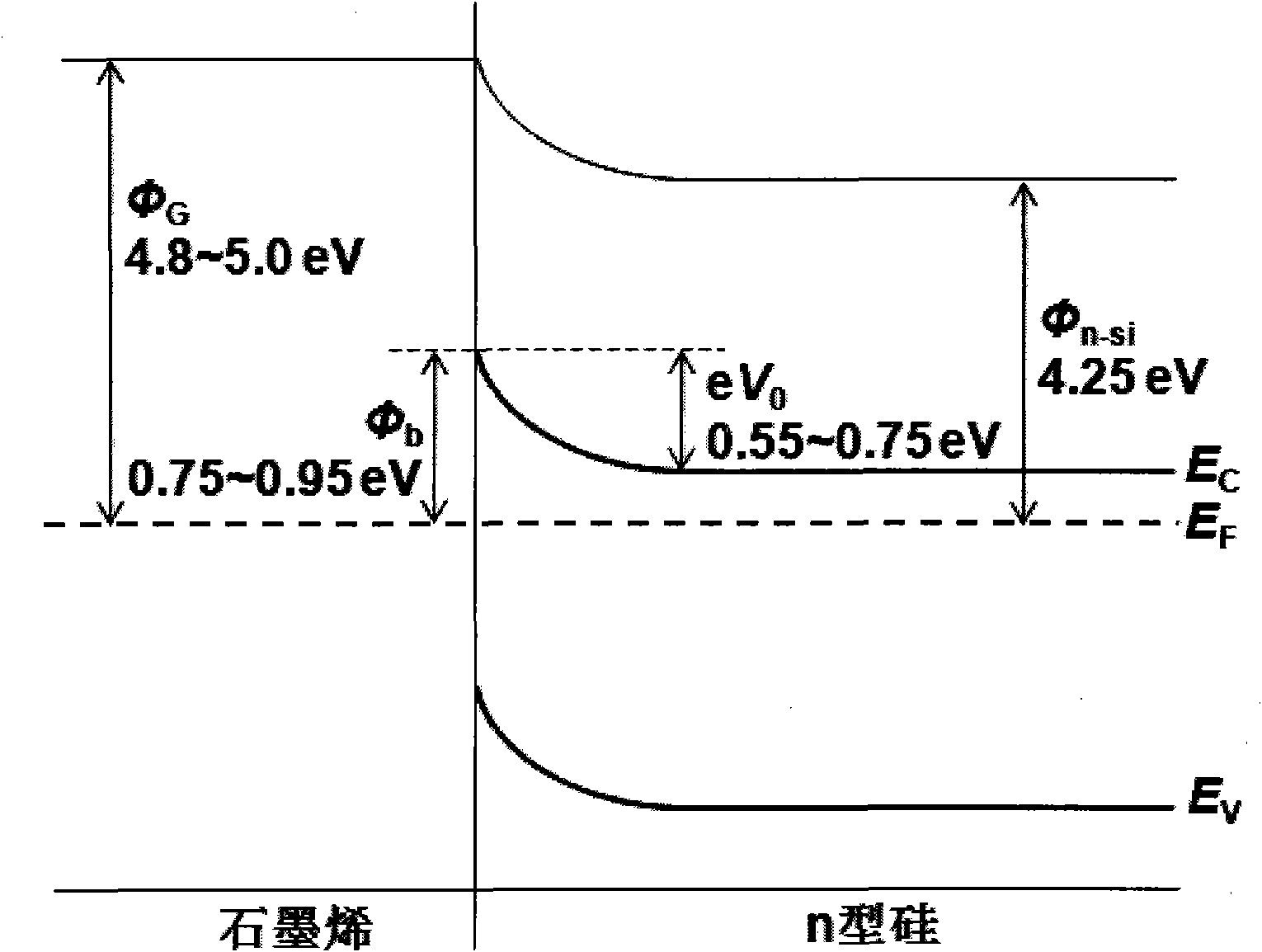

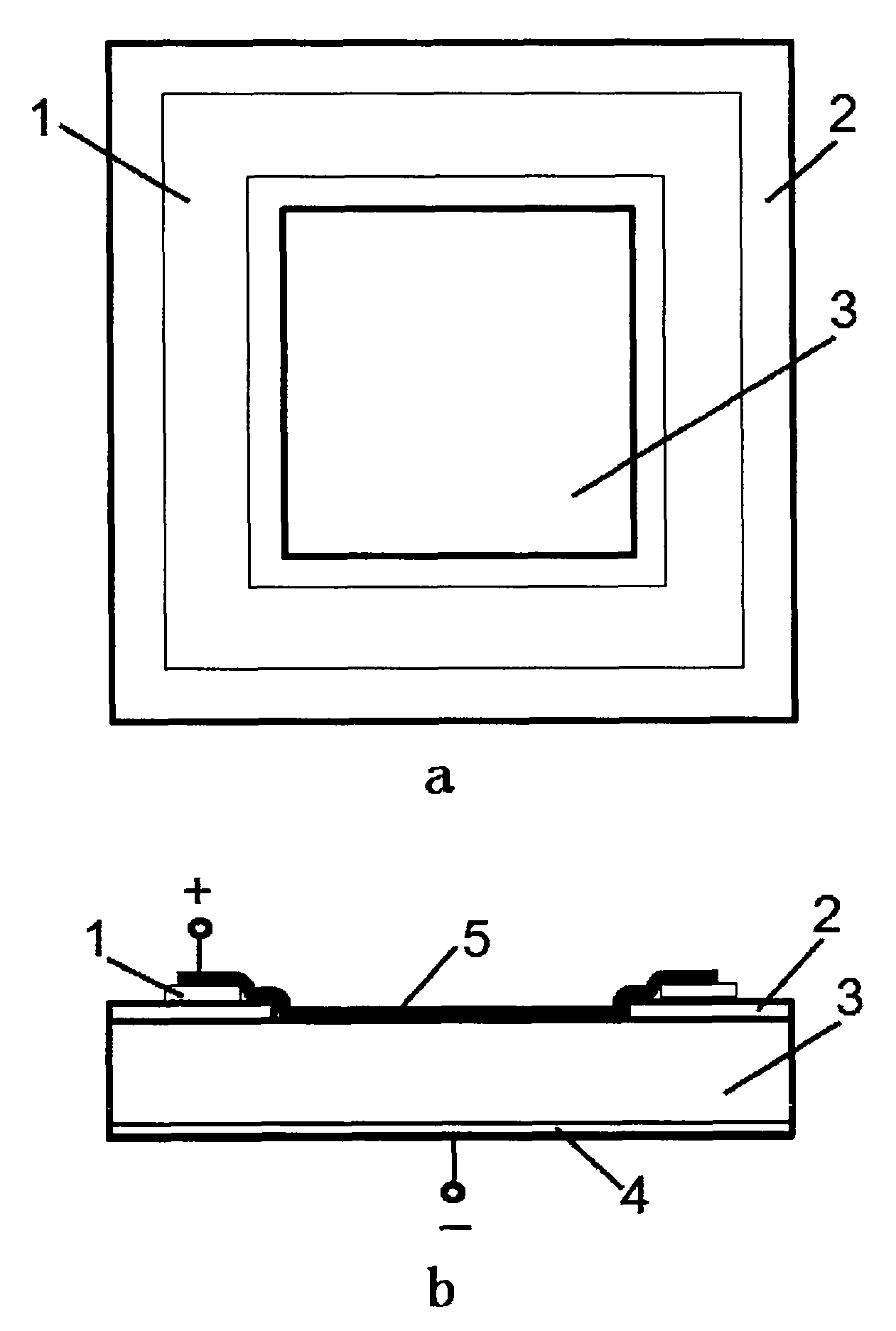

[0020] refer to figure 1 , a kind of photovoltaic cell based on graphene / silicon Schottky junction, is characterized in that, comprises titanium palladium silver TiPdAg back electrode 4, is placed on the titanium palladium silver TiPdAg back electrode 4 with n-type monocrystalline silicon n-Si 3, Silicon dioxide SiO is placed on the n-type single crystal silicon wafer n-Si 3 2 Layer 2, silicon dioxide SiO 2 There is a through hole in the middle of layer 2, silicon dioxide SiO 2 A ring-shaped gold film 1 is placed on the layer 2, the inner hole of the gold film 1, the SiO 2 The through hole in the middle of the layer 2 and the upper surface of the n-type single crystal silicon chip n-Si 3 form a step hole, and one end of the titanium palladium silver TiPdAg back electrode 4 leads out a wire, and a graphene film 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com