Method for depriving nitric oxide by plasma cooperating with low-temperature catalytic oxidation NO

A plasma and low-temperature catalysis technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of secondary pollution, easy leakage, and high reaction temperature, and achieves a small footprint and no secondary pollution. , the effect of a wide concentration range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

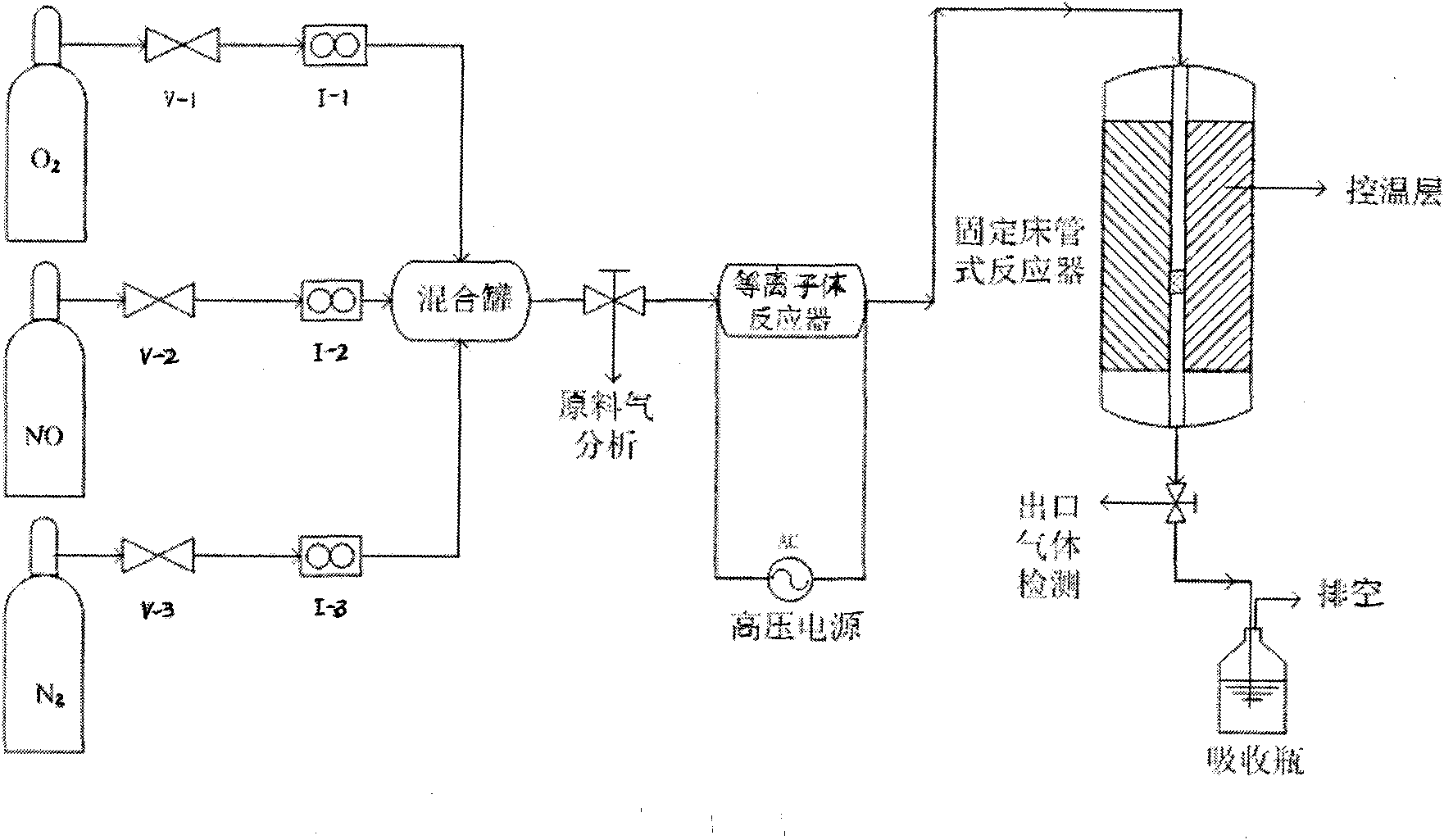

Embodiment 1

[0012] Coaxial dielectric barrier reactor plasma reactor has corundum tubes with inner and outer diameters of 20mm and 25mm respectively. A stainless steel electrode with a diameter of 10mm is inserted in the center of the corundum tube. The outer wall of the corundum tube is wound with stainless steel mesh as a high-voltage electrode. Low voltage electrode, plasma input voltage is 10V, current is 0.2A; NO volume fraction is 5×10 -4 , O 2 3%, N 2 It is balance gas, the total flow rate of mixed gas is 200ml / min, and the space velocity is 51000h -1 . Activate the mixed gas to be treated through a plasma reactor, and the activated mixed gas passes through a fixed-bed reactor equipped with MnOx-CP catalyst (0.2 g), and is heated to 250 ° C by a temperature control layer to quantitatively oxidize it to NO 2 , and then the gas enters the lye absorption bottle for absorption and utilization. The removal rate of NO reached 82% at 150°C.

Embodiment 2

[0014] Coaxial dielectric barrier reactor plasma reactor has corundum tubes with inner and outer diameters of 20mm and 25mm respectively. A stainless steel electrode with a diameter of 10mm is inserted in the center of the corundum tube. The outer wall of the corundum tube is wound with stainless steel mesh as a high-voltage electrode. Low voltage electrode, plasma input voltage is 22V, current is 0.5A. NO volume fraction is 5×10 -4 , O 2 3%, N 2 It is balance gas, the total flow rate of mixed gas is 200ml / min, and the space velocity is 12000h -1 ; The mixed gas to be treated is activated by a plasma reactor, and the activated mixed gas is passed through a fixed-bed reactor equipped with a MnOx-CA-400 catalyst (0.6 gram), and is heated to 250° C. by a temperature control layer to quantitatively oxidize to NO 2 , and then the gas enters the lye absorption bottle for absorption and utilization. The removal rate of NO reached 41% at 50℃.

Embodiment 3

[0016] Coaxial dielectric barrier reactor plasma reactor has corundum tubes with inner and outer diameters of 20mm and 25mm respectively. A stainless steel electrode with a diameter of 10mm is inserted in the center of the corundum tube. The outer wall of the corundum tube is wound with stainless steel mesh as a high-voltage electrode. Low voltage electrode, plasma input voltage is 70V, current is 1.5A; NO volume fraction is 5×10 -4 , O 2 3%, N 2 It is balance gas, the total flow rate of mixed gas is 200ml / min, and the space velocity is 60000h -1 ; The mixed gas to be treated is activated by the plasma reactor, and the activated mixed gas is passed through the MA-MnOx / TiO 2 Catalyst (0.15g) in a fixed bed reactor, heated to 250°C with a temperature control layer to quantitatively oxidize to NO 2 , and then the gas enters the lye absorption bottle for absorption and utilization. The removal rate of NO reached 56% at 100℃.

[0017] Catalyst preparation: Co-precipitation met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com