Method for preparing basic bluestone by utilizing PCB ammonium persulfate-H2SO4 micro-etched waste liquid

A technology of -H2SO4 and ammonium persulfate, which is applied in the field of production of basic copper sulfate, can solve the problems of reducing the ornamental value of water bodies, large energy loss, and large power consumption, and achieve the effects of reducing burden, realizing recycling, and reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

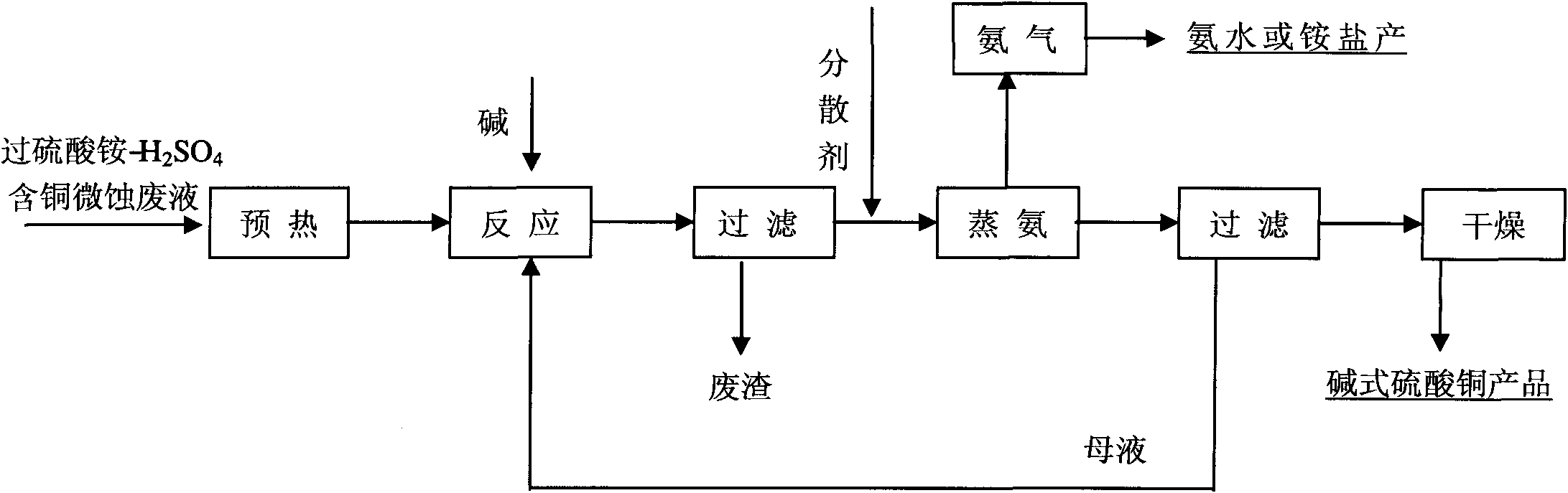

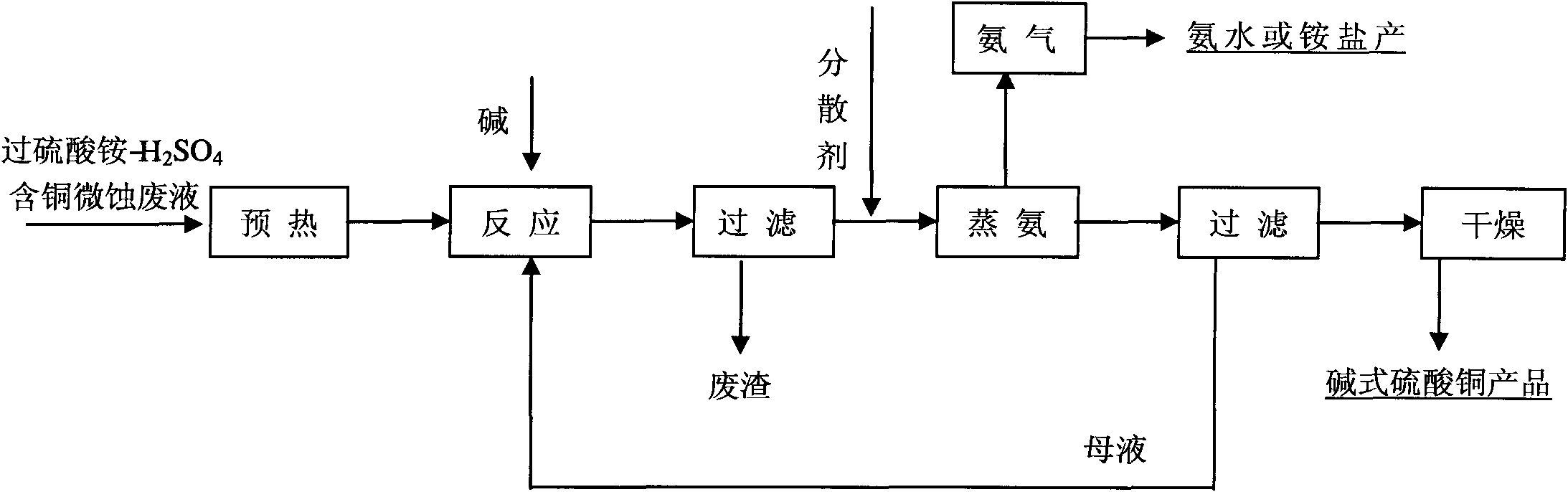

Method used

Image

Examples

Embodiment 1

[0027] at 8M 3 Add ammonium persulfate-H with a copper content of 25g / L to the enamel reaction kettle 2 SO 4 Micro-etching waste liquid 6M 3 , stirring while passing steam to make ammonium persulfate-H 2 SO 4 Microetching waste liquid was preheated to 75°C. In addition, a 30% (mass fraction) sodium hydroxide solution was preheated to 70° C. in a raw material storage tank. Start the reactor stirring paddle, open the raw material pump of sodium hydroxide and adjust the flow rate of the flowmeter at the same time, so that the sodium hydroxide solution is added in the reactor at a rate of 20L / Min, and the pH value of the reactant in the control reactor is 9.5; filter Add 1000g of sodium dodecylbenzenesulfonate to the precipitate, transfer it to the ammonia distillation reactor, and carry out reflux ammonia distillation under stirring conditions, control the ammonia distillation temperature at 70°C until the pH value drops to 7.5, stop ammonia distillation, and filter It was ...

Embodiment 2

[0029] at 8M 3 Add ammonium persulfate-H with a copper content of 50g / L to the enamel reaction kettle 2 SO 4 Micro-etching waste liquid 6M 3 , stirring while passing steam to make ammonium persulfate-H 2 SO 4 Microetching waste liquid was preheated to 75°C. In addition, a 30% (mass fraction) sodium hydroxide solution was preheated to 70° C. in a raw material storage tank. Start the reactor stirring paddle, open the raw material pump of sodium hydroxide and adjust the flow rate of the flowmeter at the same time, so that the sodium hydroxide solution is added in the reactor at a rate of 20L / Min, and the pH value of the reactant in the control reactor is 9.5; filter Add 1000g of sodium dodecylbenzenesulfonate to the precipitate, transfer it to the ammonia distillation reactor, and carry out reflux ammonia distillation under stirring conditions, control the ammonia distillation temperature at 70°C until the pH value drops to 8, stop ammonia distillation, and filter It was wa...

Embodiment 3

[0031] at 8M 3 Add ammonium persulfate-H with a copper content of 35g / L to the enamel reaction kettle 2 SO 4 Micro-etching waste liquid 6M 3 , stirring while passing steam to make ammonium persulfate-H 2 SO 4 Microetching waste liquid was preheated to 50°C. In addition, a 30% (mass fraction) sodium hydroxide solution was preheated to 50° C. in a raw material storage tank. Start the reactor stirring paddle, open the raw material pump of sodium hydroxide and adjust the flow rate of the flow meter at the same time, so that the sodium hydroxide solution is added in the reactor at a rate of 20L / Min, and the pH value of the reactant in the control reactor is 10; filter Add 2500g of sodium lignosulfonate to the precipitate, transfer it to the ammonia distillation reactor, and carry out reflux ammonia distillation under stirring conditions, control the temperature of ammonia distillation at 75°C until the pH value drops to 7.5, finish ammonia distillation, filter and wash with wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com