Biomedical material with porous calcium phosphate-chitosan composite coating

A biomedical material, porous calcium phosphate technology, applied in coatings, medical science, prostheses, etc., can solve problems such as chitosan compounding, to enhance tissue repair ability, improve safety and success rate, and promote osteoarthritis The effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

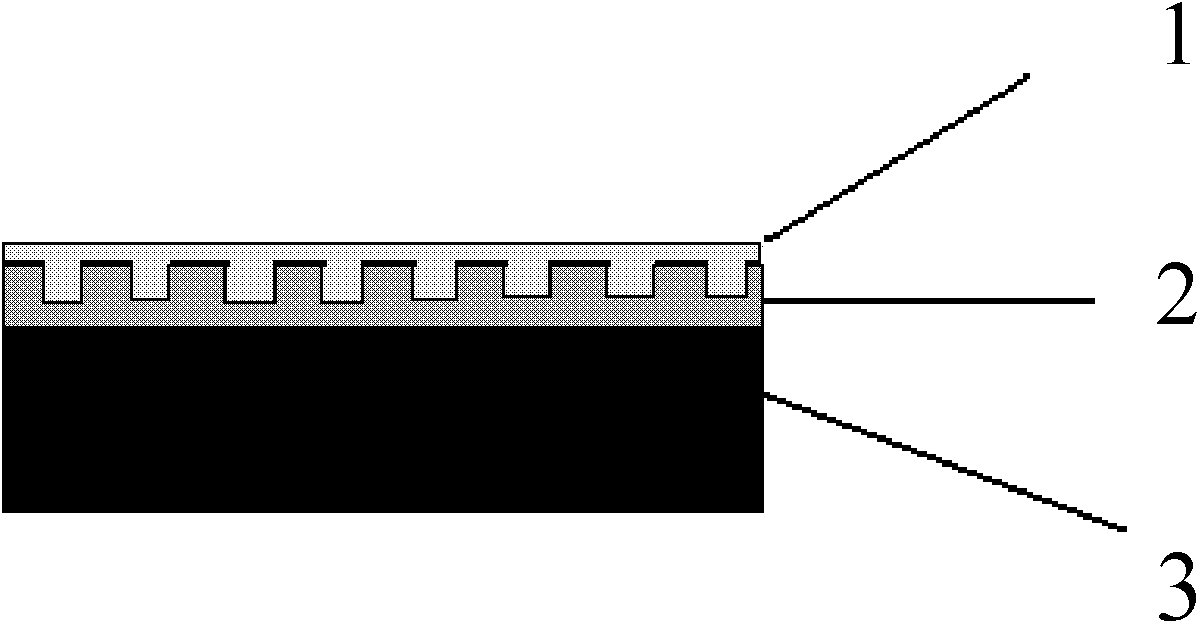

[0057] The invention provides a preparation method for directly compounding water-soluble chitosan surface layer on the surface of a porous calcium phosphate coating. The method is based on plasma spraying to prepare a porous calcium phosphate coating, and directly compound water-soluble chitosan on the surface of the porous coating. surface layer of chitosan.

[0058]The specific operation steps are:

[0059] A preparation of porous calcium phosphate coating

[0060] According to the calcium-phosphorus molar ratio of hydroxyapatite, tricalcium phosphate, etc., add the diammonium hydrogen phosphate aqueous solution with a molar concentration of 1.2-3.6 mol / L dropwise to calcium nitrate with a molar concentration of 1-3 mol / L under constant stirring In the aqueous solution, keep the reaction liquid at 30-90°C, control its pH at 9-12 with ammonia water with a concentration of 10% to 30% by mass percentage, leave it standing for 5-15 minutes after the reaction, and then age for ...

Embodiment 1

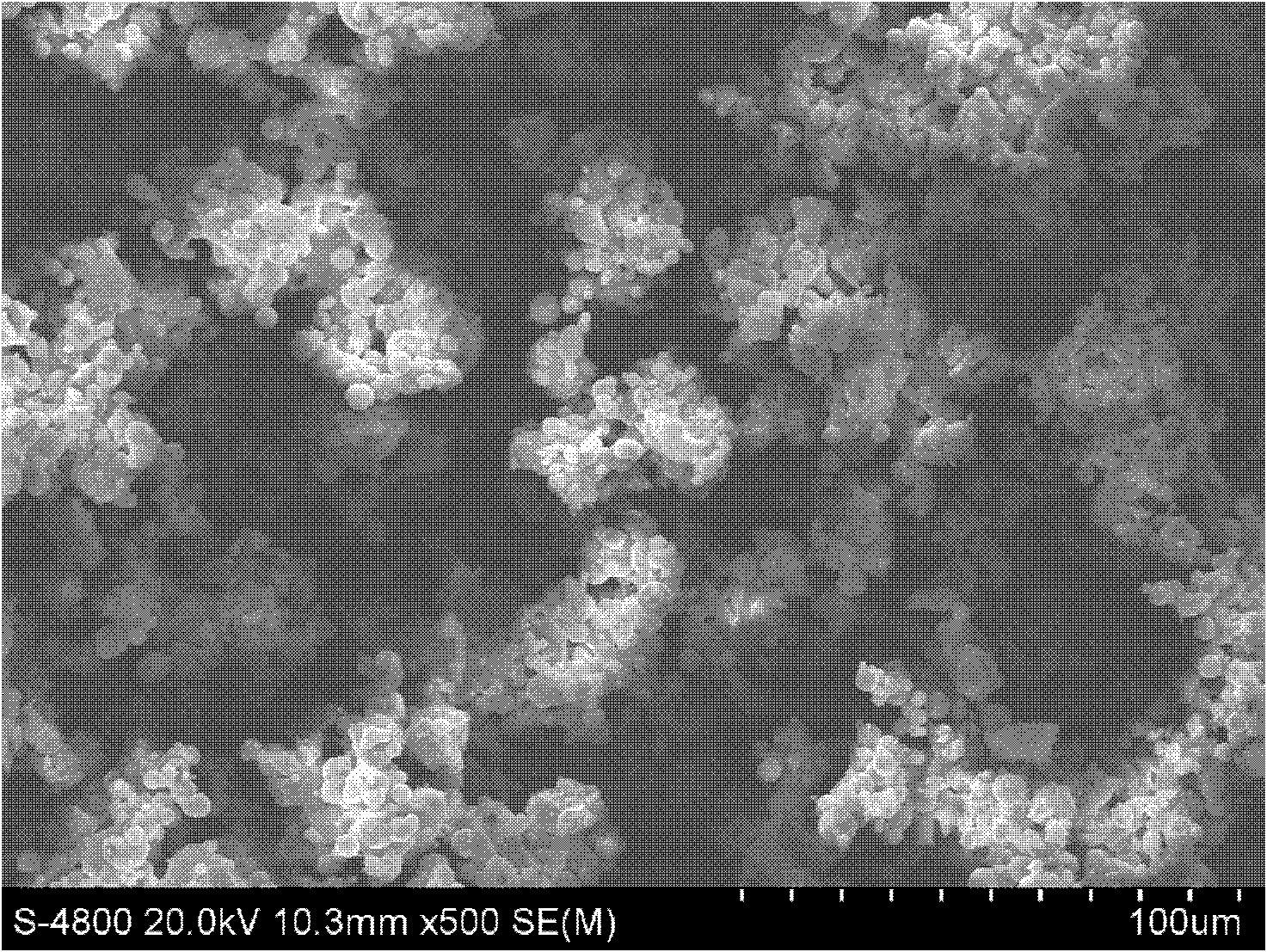

[0066] Composite chitosan coating on the hydroxyapatite coating of embodiment one powder plasma spraying

[0067] Direct use of hydroxyapatite powder. Through plasma spraying equipment, powder nozzles are used for spraying, atmospheric plasma spraying equipment is used, and finally a coating is formed on the biomedical metal substrate with a spraying thickness of 120 microns. The surface morphology of the coating was observed by scanning electron microscopy. SEM photo see Figure II . Chitosan was dissolved in ultrapure water with a concentration of 100g / L, and the coated sample was soaked in the chitosan aqueous solution under sterile conditions for 24 hours, and then air-dried for 12 hours in an ultra-clean bench. The early antibacterial performance of its composite coating (chitosan concentration 100g / L) is compared with the porous calcium phosphate-chitosan composite coating (chitosan concentration 100g / L) (MTT method for the detection of the proliferation of Staphyloco...

Embodiment 2

[0068] Embodiment two compound chitosan coating on the hydroxyapatite coating of liquid plasma spraying

[0069] Press Ca 10 (PO 4 ) 6 (OH) 2 The molar ratio of calcium to phosphorus (1.67), under constant stirring, the diammonium hydrogen phosphate aqueous solution with a molar concentration of 2.8mol / L is added dropwise to the calcium nitrate aqueous solution with a molar concentration of 2.4mol / L, and the reaction solution is kept at 70°C. Ammonia water with a concentration of 25% by mass was used to control the pH at 10.5, and after the reaction, it was allowed to stand for 10 minutes, and then aged for 24 hours to obtain a hydroxyapatite suspension with a solid content of 34% for use. Using plasma spraying equipment, the nozzle adopts an atomizing nozzle, and the liquid plasma spraying method is used. After the droplets in the precursor liquid are broken, refined, evaporated, sintered, and melted, a coating is finally formed on the biomedical metal substrate. The spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| release amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com