Heat pump carrier gas flow-through type continuous drying equipment

A technology of drying equipment and carrier gas, applied in lighting and heating equipment, heating to dry solid materials, drying solid materials, etc., can solve the problems of reduced effective working volume of dryers, unfavorable equipment maintenance and repair, and increased volume of drying towers, etc. , to achieve the effect of reducing operating costs, simple structure, and increasing overall reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

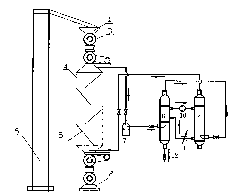

Image

Examples

Embodiment 1

[0015] The equipment disclosed by the invention is used to dry distiller's grains. Distiller's grains are an important by-product of liquor production. According to statistics, the output of distiller's grains has reached 15 million tons. Faced with such a huge amount of resources, my country has conducted a lot of research on this, for example, using distiller's grains to cultivate edible fungi, extract compound amino acids and trace elements, extract phytic acid and calcium phytate, extract protein, and produce amylase or cellulase , using vinasse anaerobic fermentation to recover biogas, produce feed protein, and produce γ-aminobutyric acid, etc. Although there are so many methods, the utilization rate of distiller's grains is still not high at present. A limiting factor that limits the full utilization of distiller's grains resources is that the pH of freshly discarded grains is low, and the moisture content is high (above 60%), which is easy to spoil and deteriorate, which...

Embodiment 2

[0018] Drying of wheat is carried out with the equipment disclosed by the present invention. With a volume of 5m 3 The heat pump carrier gas flow-through continuous drying equipment is used to dry wheat with a water content of 17%. The drying tower used is 1.14m in diameter and 5m in height. There are 5 baffles installed inside, and the installation angle is 35°. It is equipped with SL80WD Luo Ci fan (motor power 7.5kw), carrier gas flow rate is 15m 3 / min, equipped with a corresponding heat pump system, adjust the inlet temperature of the carrier gas (air) to 47-50°C, the cooling temperature to 4-6°C, the drying speed of the material is 15 tons of wheat / day, and the power of the heat pump system is 5kW / h, the moisture content of export wheat is 12.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com