Polyphenyl ether compound used for solar battery connecting box

A technology for solar cells and polyphenylene ethers, applied in the fields of polyphenylene ether compositions and halogen-free flame retardant polyphenylene ether compositions, can solve problems such as difficulty in meeting performance requirements, and achieve good rigidity, good flame retardant performance, and insulating performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

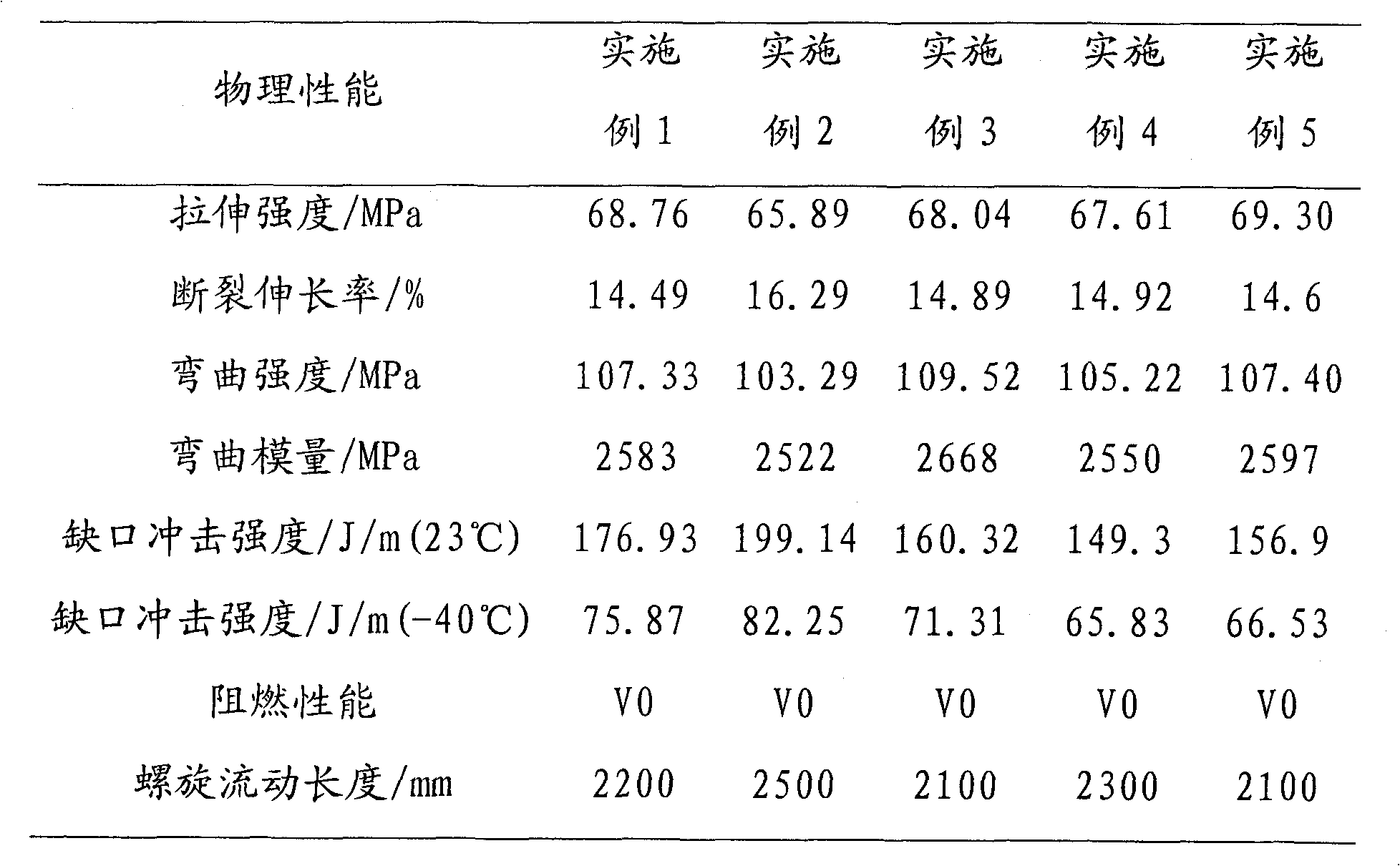

Examples

Embodiment 1

[0028] With 70 parts by weight of polyphenylene ether resin (intrinsic viscosity 0.45dL / g), 30 parts by weight of high-impact polystyrene resin (melt flow rate 4g / 10min), 3 parts by weight of low-density polyethylene, 12 parts by weight The liquid organophosphate flame retardant (tetraphenyl bisphenol A diphosphate) of part, the antioxidant 1010 of 0.5 part by weight, the antiultraviolet agent zinc oxide of 0.2 part by weight stirred 4 minutes in high-speed mixer; Mixed The uniform material is put into the twin-screw extruder for melt extrusion and granulation. The length-to-diameter ratio of the twin-screw extruder is 40, the screw speed is 320rpm / min, the feeding speed is 300rpm / min, and the temperature of each section of the screw barrel is 240-285°C. Machine diced.

Embodiment 2

[0030] With 60 parts by weight of polyphenylene ether resin (intrinsic viscosity 0.5dL / g), 40 parts by weight of high-impact polystyrene resin (melt flow rate 2g / 10min), 1 part by weight of low-density polyethylene, 11 parts by weight The liquid organophosphate flame retardant (tetraphenylbisphenol A diphosphate) of part, the antioxidant 168 of 1.0 part by weight, the anti-ultraviolet agent titanium dioxide of 0.5 part by weight stirred 4 minutes in high-speed mixer; Mix homogeneously The materials are put into the twin-screw extruder for melt extrusion and granulation. The length-to-diameter ratio of the twin-screw extruder is 40, the screw speed is 320rpm / min, the feeding speed is 300rpm / min, and the temperature of each section of the screw barrel is 240-285°C. Machine diced.

Embodiment 3

[0032] With 80 parts by weight of polyphenylene ether resin (intrinsic viscosity 0.3dL / g), 20 parts by weight of high-impact polystyrene resin (melt flow rate 10g / 10min), 5 parts by weight of low-density polyethylene, 5 parts by weight The solid organophosphate flame retardant (tetraphenyl bisphenol A diphosphate) of part, the antioxidant DLTP of 0.6 part by weight, the antiultraviolet agent carbon black of 0.1 part by weight stirred 4 minutes in high-speed mixer; Mixed The uniform material is put into the twin-screw extruder for melt extrusion and granulation. The length-to-diameter ratio of the twin-screw extruder is 40, the screw speed is 320rpm / min, the feeding speed is 300rpm / min, and the temperature of each section of the screw barrel is 240-285°C. Machine diced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com