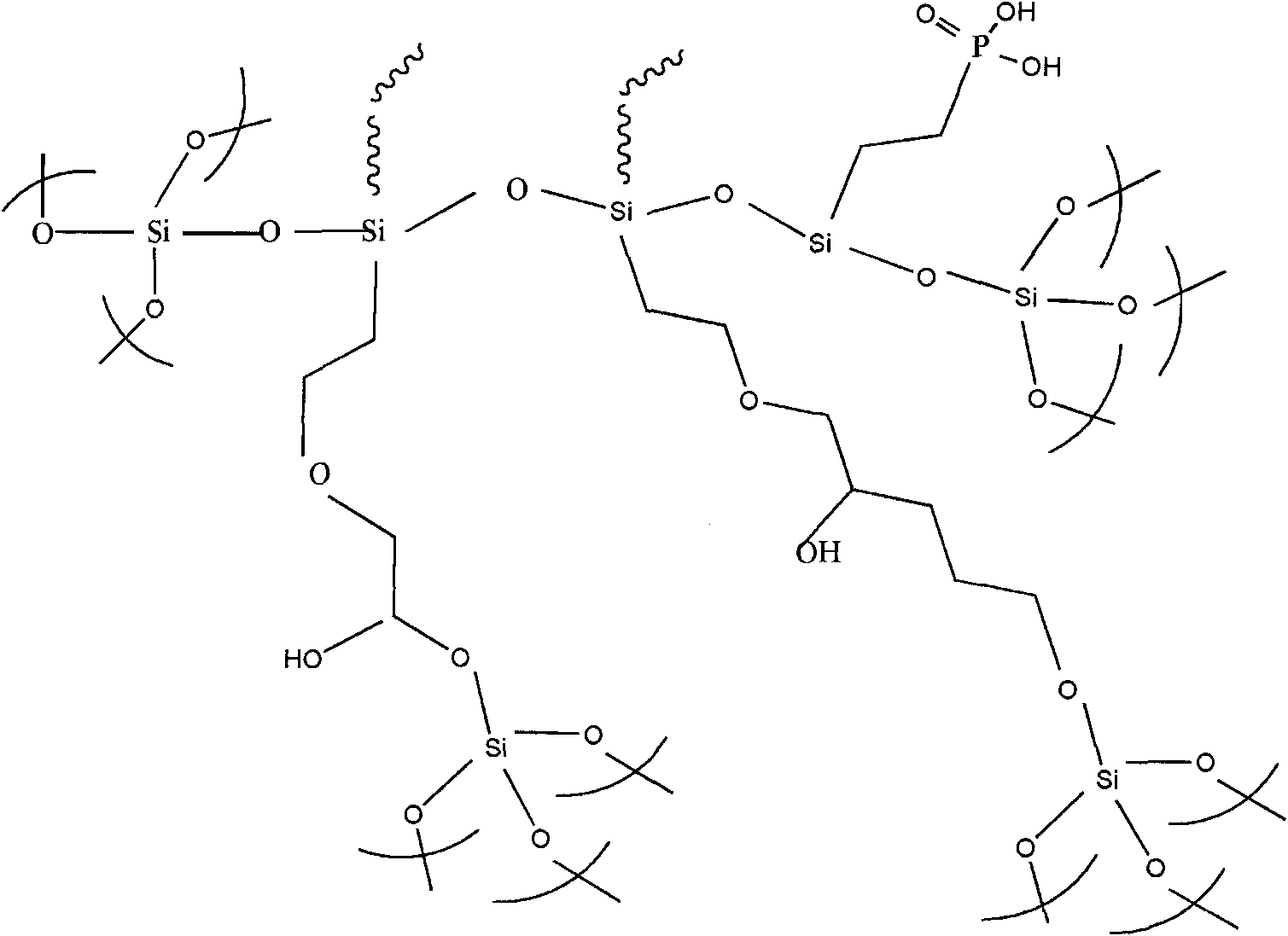

Intermediate-temperature proton exchange film of organic polysiloxane phosphonic acid group and preparation method thereof

A technology of polysiloxane phosphonic acid group and proton exchange membrane, which is applied in the direction of fuel cells, structural parts, fuel cell parts, etc., can solve the problems of poor mechanical strength and low electrical conductivity, and achieve long service life and flexibility Good resistance, the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the phosphonic acid ethyltrimethoxysilane used is: according to trimethoxy hydrogen siloxane: vinylphosphonic acid: platinum acetylacetonate: the mol ratio of methyl alcohol is 1.5: 1.5: 1.5 * 10 -3 : 20 Weigh the raw materials. Under the protection of nitrogen, add accurately measured trimethoxyhydrogensilane and platinum acetylacetonate into a pre-baked and dried three-necked flask equipped with electromagnetic stirring, irradiate under ultraviolet light, and stir for 10 minutes at the same time; Methanol was made into a solution, which was added dropwise to the reactor under the protection of nitrogen and cooled by a water bath at room temperature, and then continued to react for 1.0 hour; adding activated carbon, stirring for 10 minutes, filtering to remove the catalyst platinum acetylacetonate, and then rotating to remove the solvent to obtain Pale yellow transparent viscous liquid; obtained by vacuum drying at 130°C for 1.0 hour.

[0033...

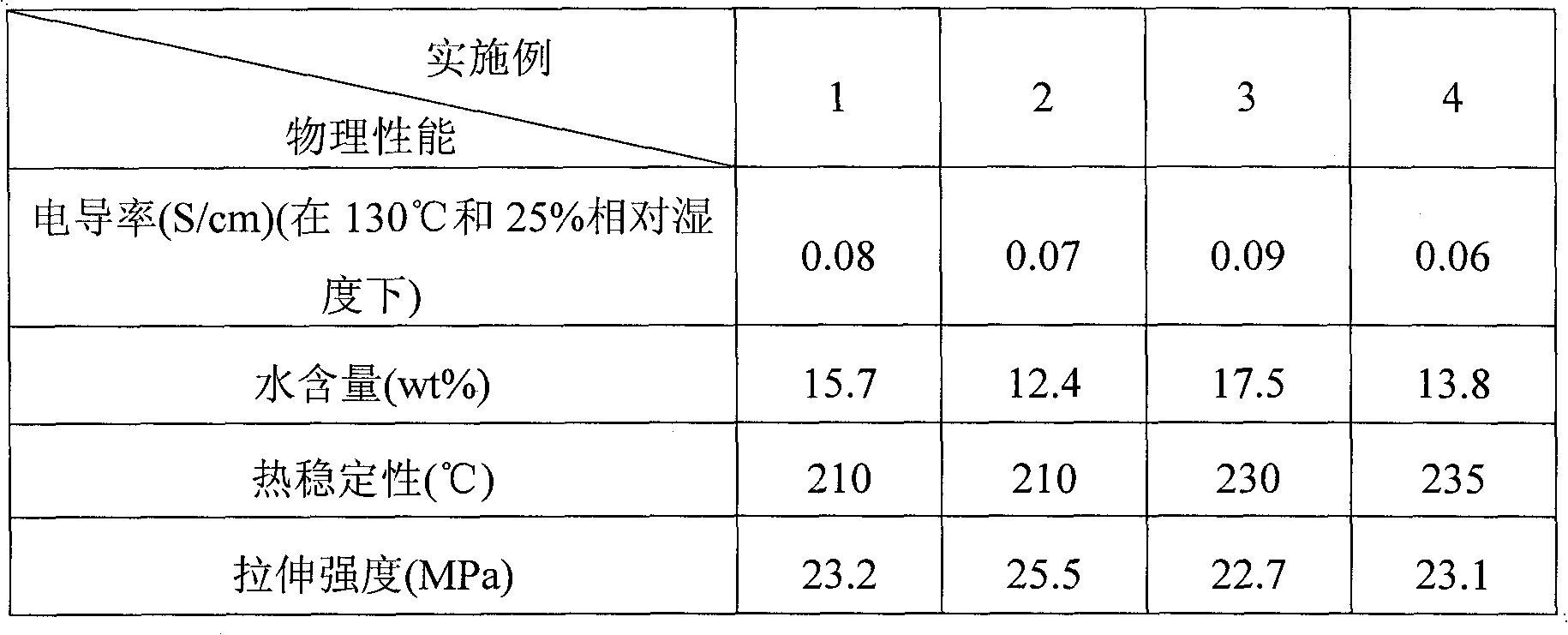

Embodiment 1

[0037] The specific steps of the preparation method of organopolysiloxane phosphonic acid-based medium-temperature proton exchange membrane are as follows:

[0038] 1) Preparation of sol: according to the raw materials γ-(2,3-epoxypropoxy)propyltrimethoxysilane: 2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane: ethyl phosphonate The molar ratio of trimethoxysilane is 1.0: 1.0: 1.5. Select the raw material and add it to the reactor, then add methanol with a molar ratio of 7.0 to GPTMS, then add deionized water with a molar ratio of 5.0 to GPTMS, and stir at room temperature for 24 hours, a stable and clear sol was obtained;

[0039] 2) Preparation of gel film: Pour the sol solution obtained in step 1) into a polytetrafluoroethylene mold plate, cover with aluminum foil, then put it into an oven, gelatinize at 65-70°C, that is, dehydration and dealcoholization for 12 hours, When the sol solution becomes viscous, remove the aluminum foil and continue to gel for 45 minutes to obtain a...

Embodiment 2

[0043] The specific steps of the preparation method of organopolysiloxane phosphonic acid-based medium-temperature proton exchange membrane are as follows:

[0044] 1) Preparation of sol: according to the raw materials γ-(2,3-epoxypropoxy)propyltrimethoxysilane: 2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane: phosphonic acid benzene The molar ratio of ethyltriethoxysilane is 1.0:0.5:0.7, select the raw material, add it to the reactor, then add methanol with a molar ratio of 6.0 to GPTMS, then add deionized water with a molar ratio of 4.0 to GPTMS, room temperature After stirring for 18 hours, a stable and clear sol was obtained;

[0045] 2) Preparation of gel film: Pour the sol solution obtained in step 1) into a polytetrafluoroethylene mold, cover with aluminum foil, then put it into an oven, and gel (dehydration and dealcoholization) at 65-70°C for 24 hours , until the sol solution becomes viscous, remove the aluminum foil, and continue to gel for 50 minutes to obtain a gel f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com