Co-mixing film of ethylene-acetic acid ethylene copolymer and polysulfone and method for preparing same

A vinyl acetate copolymer, vinyl acetate copolymerization technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. and other problems, to achieve the effect of low complement activation, excellent mechanical properties, and non-coagulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

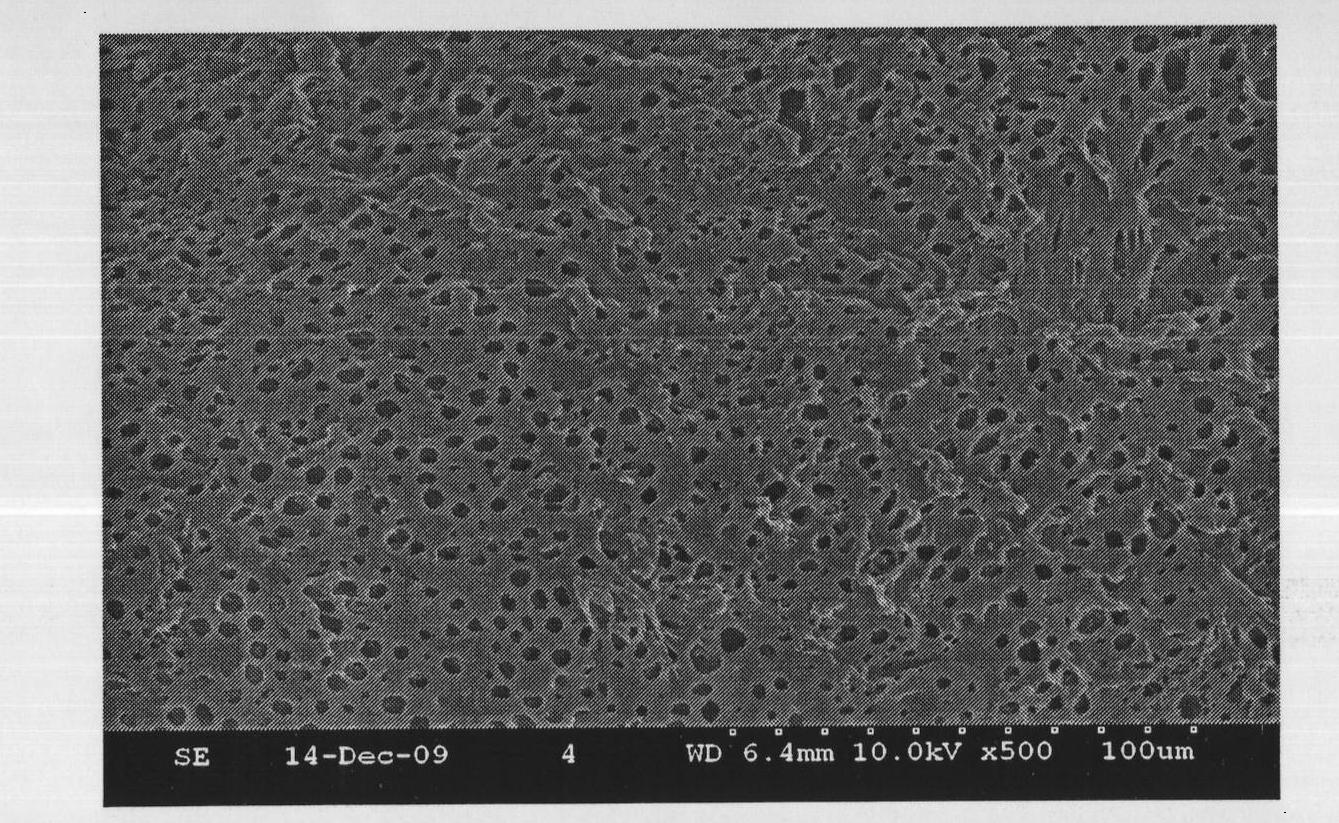

[0030] The ingredients and mass percentages are as follows: EVA 5%, polysulfone 10%, dimethyl sulfoxide 75%, PVP (K30) 10%. Put the above raw materials into the container and mix and stir at 75°C to make a uniform spinning stock solution, and let it stand still. The prepared spinning stock solution was filtered through a 3-micron filter element, and then vacuumed and degassed at a vacuum degree of -0.6 bar to obtain a spinning solution, which was transferred to a feeding ax for later use. Heat the film-making solution to 70°C, and apply the film-making solution to a 200-mesh non-woven support layer at a speed of 20cm / min through a film scraper, and immerse the support layer coated with the film-making solution in a 45°C A composite membrane is formed in coagulation bath water, and the composite membrane is soaked in deionized water for 1 day and then dried to obtain a composite ultrafiltration membrane for blood purification.

Embodiment 2

[0032] The ingredients and mass percentages are as follows: EVA 10%, polysulfone 5%, dimethylformamide 75%, polyethylene glycol (molecular weight 10000) 10%. Put the above raw materials into the container, mix and stir at 80°C to make a uniform spinning stock solution, and let it stand still. The prepared spinning stock solution was filtered through a pore size filter element of 5 microns, and then vacuumized and degassed at a vacuum degree of -0.9 bar to obtain a spinning solution, which was transferred to a feeding ax for later use. Heat the film-making solution to 75°C, and apply the film-making solution to a 300-mesh non-woven support layer at a speed of 100cm / min through a film scraper, and immerse the support layer coated with the film-making solution in a 60°C A composite membrane is formed in coagulation bath water, soaked in deionized water for 3 days and then dried to obtain a composite ultrafiltration membrane for blood purification.

Embodiment 3

[0034] The ingredients and mass percentages are as follows: EVA 10%, polysulfone 10%, dimethylacetamide 75%, potassium nitrate 5%. Put the above raw materials into the container and mix and stir at 75°C to make a uniform spinning stock solution, and let it stand still. The prepared spinning stock solution was filtered through a 4-micron filter core, and then vacuumed and degassed at a vacuum degree of -0.8 bar to obtain a spinning solution, which was transferred to a feeding ax for later use. Heat the film-making liquid to 70°C, and apply the film-making liquid to a 300-mesh non-woven support layer at a speed of 80 cm / min through a film scraper, and immerse the support layer coated with the film-forming liquid in a 50°C A composite membrane is formed in coagulation bath water, soaked in deionized water for 2 days and then dried to obtain a composite ultrafiltration membrane for blood purification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com