Method for purifying ganoderic acid T and ganoderic acid Me based on chemical synthesis method

A technology of chemical synthesis and purification method, which is applied in the field of purification of ganoderma acid T and ganoderma acid Me, can solve the problems of expensive equipment, limited enlargement prospect, unsuitability for industrialized large-scale production, etc., and achieve simplification of separation difficulty, enhancement of separation efficiency, The effect of convenient promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

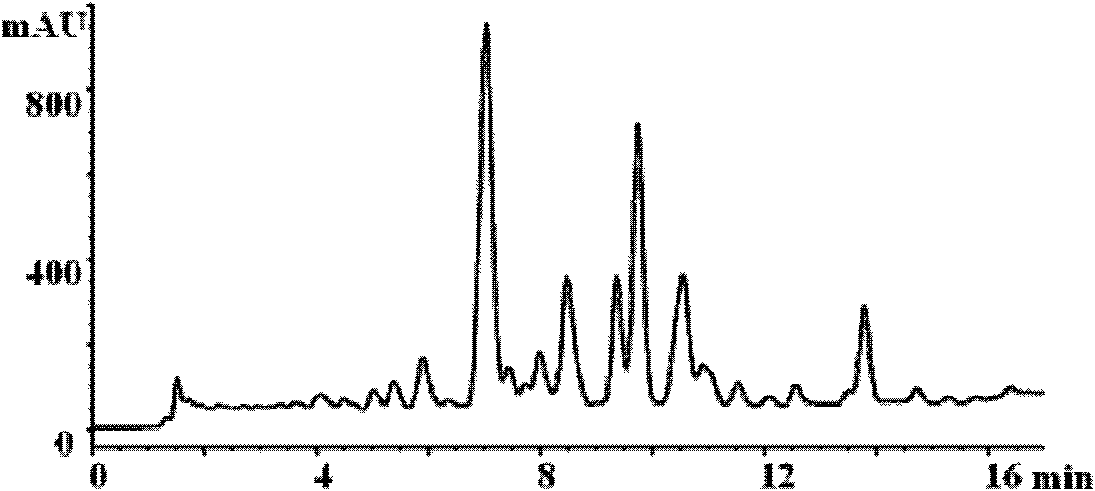

[0051] 1. Weigh 100g of stem cell powder fermented from Ganoderma lucidum mycelium, add 1L of ethyl acetate, extract terpenoids from Ganoderma lucidum stem cells, make Ganoderma lucidum cell crude extract, and use a rotary evaporator to concentrate it into an extract , Obtain 10.3 g of extract-like substance. HPLC analysis such as figure 1 , which contains 0.52g of ganoderma acid T and 0.3g of ganoderma acid Me.

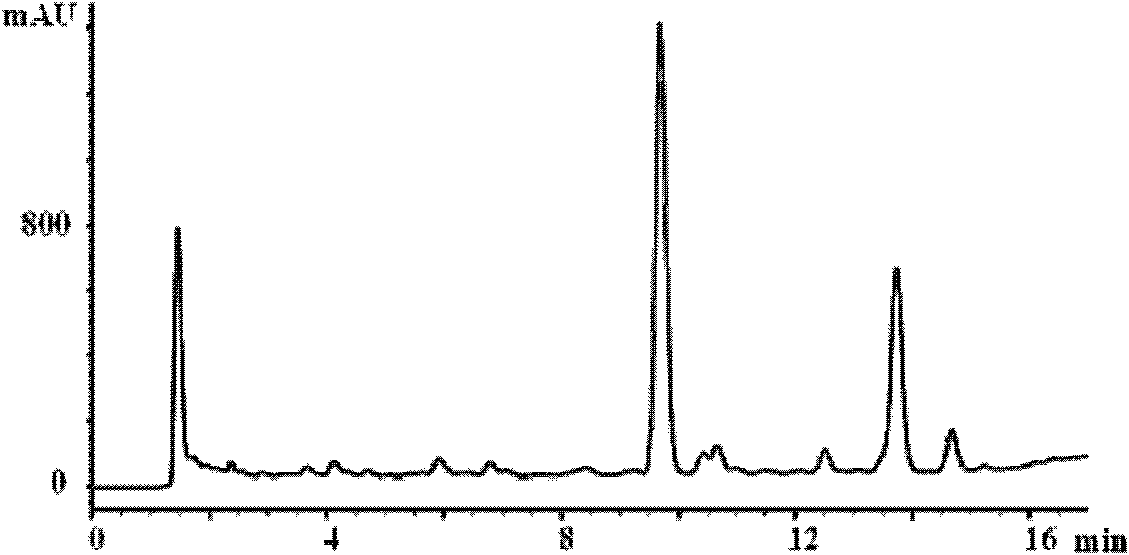

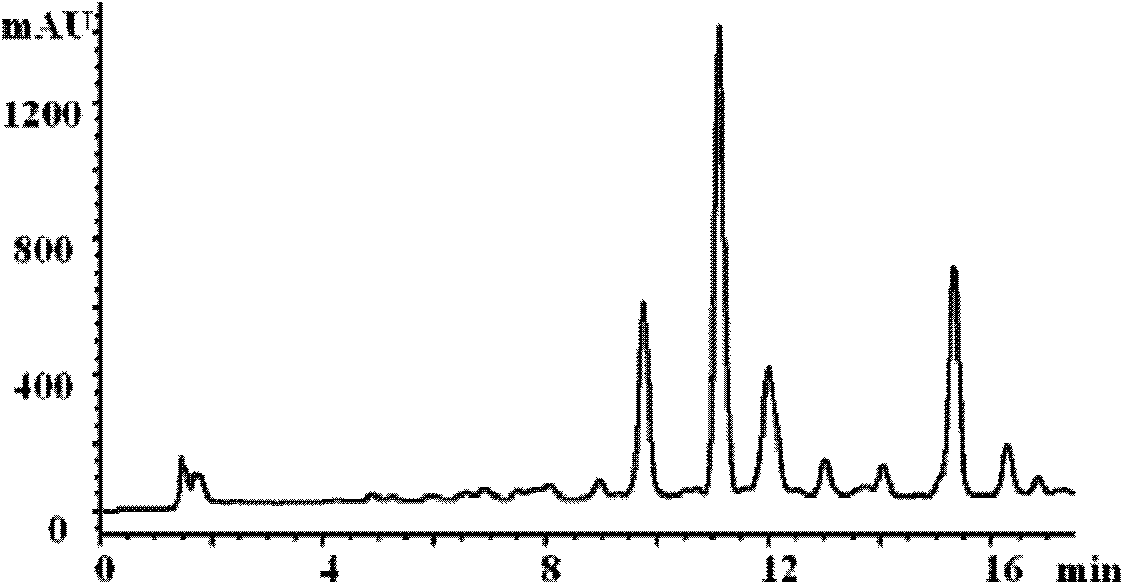

[0052] 2. Redissolve the extract of Ganoderma lucidum cells in 1L of dichloromethane, add 50mL of acetic anhydride and 3g of DMAP as a catalyst, and carry out the acetylation reaction in a water bath at 40°C for 8 hours. After the reaction, the catalyst DMAP and unreacted acetic anhydride in the reaction system were extracted with 500 mL of HCl solution with a hydrogen ion concentration of 0.06 mol / L. After liquid separation, the aqueous phase containing DMAP was used to recover DMAP, and the organic phase containing ganoderma acid was processed by rotary evaporati...

Embodiment 2

[0056] 1. Weigh 100g of stem cell powder fermented from Ganoderma lucidum mycelium, add 1L of ethyl acetate, extract terpenoids from Ganoderma lucidum stem cells, make Ganoderma lucidum cell crude extract, and use a rotary evaporator to concentrate it into an extract , Obtain 10.3 g of extract-like substance. HPLC analysis such as figure 1 , which contains 0.52g of ganoderma acid T and 0.3g of ganoderma acid Me.

[0057] 2. Redissolve the Ganoderma lucidum cell extract in 1L of dichloromethane, add 50mL of acetic anhydride and 4ml of pyridine as a catalyst, and carry out the acetylation reaction in a water bath at 40°C for 8 hours. After the reaction, the catalyst DMAP and unreacted acetic anhydride in the reaction system were extracted with 500 mL of HCl solution with a hydrogen ion concentration of 0.06 mol / L. After liquid separation, the aqueous phase containing DMAP was used to recover DMAP, and the organic phase containing ganoderma acid was processed by rotary evaporat...

Embodiment 3

[0061] 1. Weigh 100g of stem cell powder fermented from Ganoderma lucidum mycelium, add 1L of ethyl acetate, extract terpenoids from Ganoderma lucidum stem cells, make Ganoderma lucidum cell crude extract, and use a rotary evaporator to concentrate it into an extract , Obtain 10.3 g of extract-like substance. HPLC analysis such as figure 1 , which contains 0.52g of ganoderma acid T and 0.3g of ganoderma acid Me.

[0062] 2. Redissolve the Ganoderma lucidum cell extract in 1L of dichloromethane, add 50mL of acetic anhydride and 0.3g of DMAP as a catalyst, and carry out the acetylation reaction in a water bath at 40°C for 8 hours. After the reaction, the catalyst DMAP and unreacted acetic anhydride in the reaction system were extracted with 500 mL of HCl solution with a hydrogen ion concentration of 0.06 mol / L. After liquid separation, the aqueous phase containing DMAP was used to recover DMAP, and the organic phase containing ganoderma acid was processed by rotary evaporation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com