Epoxy resin adhesive for manufacturing blades of wind driven generator and preparation method thereof

A wind turbine, epoxy resin technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the technical requirements of wind turbine blades, the decrease of material strength and modulus, and the high cost of adhesives problems, to achieve the effect of improving toughness and anti-cracking performance, improving strength and modulus, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

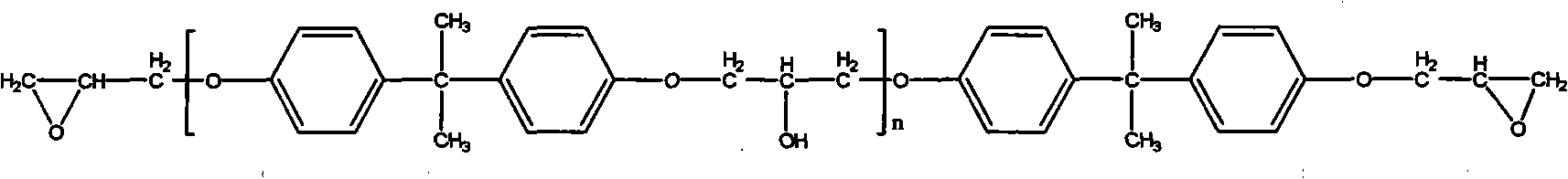

Image

Examples

Embodiment 1

[0061] Raw materials for the resin part: bisphenol A epoxy resin E-51-55 parts; 1,6-hexanediol diglycidyl ether-6 parts, allyl glycidyl ether-2 parts, glycidyl methacrylate -2 parts; nano-calcium carbonate-20 parts; vinylon fiber-6 parts, the fiber length is 300 microns; epoxy-terminated liquid nitrile rubber-3 parts, silane coupling agent KH560-1 part; organic bentonite-5 parts.

[0062] The raw materials of the curing agent part: polyetheramine D230-45 parts; nano calcium carbonate-28 parts; vinylon fiber-8 parts, the fiber length is 300 microns; organic bentonite-4 parts.

[0063] The nano-calcium carbonate powder plays the role of filling and anti-sedimentation, and the vinylon fiber mainly plays the role of strengthening and preventing the cracking of the adhesive matrix, and also plays the role of filling.

[0064] Preparation:

[0065] Prepare the mixing equipment, prepare the two parts of raw resin and curing agent separately, add the raw materials of the above resin ...

Embodiment 2

[0068] The raw materials of the resin part: bisphenol A type epoxy resin E-51-35 parts, bisphenol F type epoxy resin -15 parts; polypropylene glycol diglycidyl ether -3.5 parts, propylene oxide methyl ether -2 parts; Calcium carbonate whisker-13 parts, nanofiber wollastonite powder-10 parts; glass fiber-10 parts, the fiber length is 350 microns; carboxyl-terminated liquid nitrile rubber-4 parts, silane coupling agent KH560-1.5 parts; gas phase two Silica - 6 parts.

[0069] The raw materials of the curing agent part: polyetheramine D230-40 parts, isophorone diamine-10 parts, tetraethylenepentamine-3 parts; calcium carbonate whiskers-27 parts; glass fiber-10 parts, the fiber length is 350 micron; fumed silica - 5 parts.

[0070] The preparation method is the same as in Example 1.

Embodiment 3

[0072] Raw materials for the resin part: bisphenol F epoxy resin standard type - 32 parts; butanediol diglycidyl ether - 3 parts; nano silicon dioxide - 10 parts; carbon fiber - 8 parts, the fiber length is 180 microns; Silica - 3 parts.

[0073] The raw materials of the curing agent part: polyamide D230-40 parts; nano-silica-8 parts, zinc oxide whiskers-2 parts; carbon fiber-20 parts, the fiber length is 180 microns; fumed silica-2 parts.

[0074] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com