Preparation method of high-purity spherical full-pore silica gel particles

A spherical and particle technology, applied in the field of preparation of high-purity spherical full-porous silica gel particles, can solve the problems of inability to meet large-scale industrial production, unfavorable to environmental protection, large particle size range, etc., and achieve pore size distribution that is controllable and avoided The effect of agglomeration, shape deformation, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

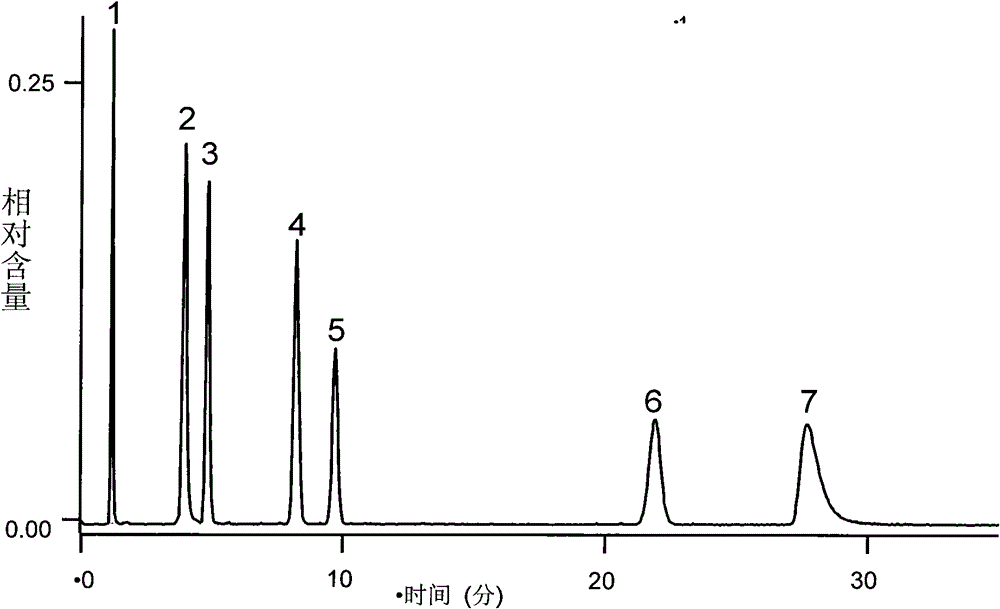

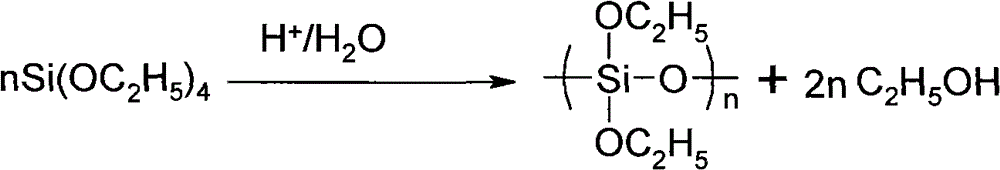

[0027] A preparation method of high-purity spherical full-porous silica gel particles: Add 200mL tetraethyl orthosilicate, 150mL absolute ethanol and 170mL deionized water into a 1L three-necked bottle, adjust the pH value to 3.5 with hydrochloric acid, and store at 26°C After stirring for 18 hours, the temperature was raised to 85° C. for distillation to remove ethanol, and a colorless liquid with a viscosity of 0.4 Pa·s was obtained after cooling to room temperature.

[0028] In a 1L three-necked flask, add 300g of deionized water, 80g of absolute ethanol and 7g of surfactant, among which 6.3g of Tween 20 and 0.7g of sodium dodecylbenzenesulfonate are mixed and stirred for 30 minutes to form a uniform water phase solution; in a 150mL beaker, take 75mL polytetraethoxysilane liquid (viscosity of 0.4Pa s) and 40mL cyclohexane and mix evenly to form an oil phase solution; add the oil phase solution to the water phase under mechanical stirring, and stir for 80 After 10 minutes, a...

Embodiment 2

[0030] A preparation method of high-purity spherical full-porous silica gel particles: Add 100mL tetraethyl orthosilicate, 100mL absolute ethanol and 80mL deionized water into a 1L three-necked bottle, adjust the pH value to 4 with hydrochloric acid, and set the temperature at 24°C After stirring for 19 hours, the temperature was raised to 95° C. for distillation to remove ethanol, and a colorless liquid with a viscosity of 0.3 Pa·s was obtained after cooling to room temperature.

[0031] In a 1L three-necked flask, add 400g of deionized water, 200g of absolute ethanol and 9g of surfactant, among which 8.1g of Tween 80 and 0.9g of sodium dodecylsulfonate are mixed, and stirred for 40 minutes to form a uniform aqueous phase solution ;In a 150mL beaker, take 50mL of polytetraethoxysilane liquid (viscosity is 0.3Pa s) and 40mL of aromatic alkanes and mix evenly to form an oil phase solution; add the oil phase solution to the water phase under mechanical stirring, and stir for 100 ...

Embodiment 3

[0033] A preparation method of high-purity spherical full-porous silica gel particles: add 2L tetraethyl orthosilicate, 1.5L absolute ethanol and 1.5L deionized water into a 10L container and mix, adjust the pH value to 2.5 with hydrochloric acid, and set the temperature at 25 After stirring at °C for 16 hours, the temperature was raised to 90°C for distillation to remove ethanol, and after cooling to room temperature, a colorless liquid with a viscosity of 0.25 Pa·s was obtained.

[0034]The process of industrialized production is: in a 20L reactor, add 6L deionized water, 1600g absolute ethanol and 150g surfactant, wherein 136g Triton X-100, 14g sodium dodecylbenzenesulfonate, stir for 30 minutes to form a homogeneous aqueous solution. In a 3L beaker, take 1.5L polytetraethoxysilane liquid (viscosity 0.25Pa·s) and mix with 1L n-heptane to form an oil phase solution. Add the oil phase solution to the water phase solution under mechanical stirring. The stirring machine is a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com