Method for preparing titanium nano particle and polyester composite paint and composite paint prepared by same

A technology of nano-particles and composite coatings, applied in the direction of polyester coatings, coatings, etc., can solve the problems of easy agglomeration, affecting material properties, and high production costs, and achieve good mechanical properties, reduce production costs, and evenly distribute the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

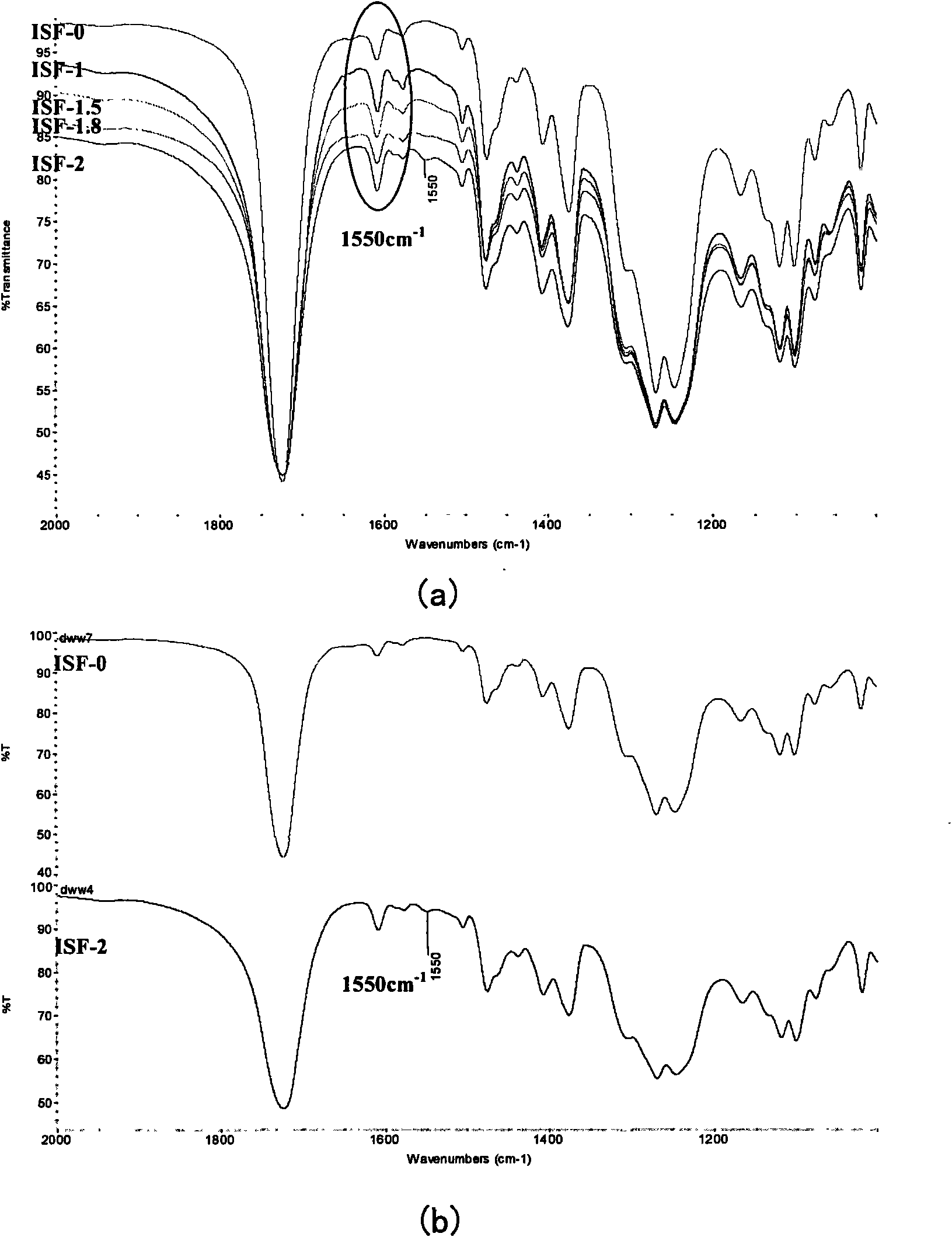

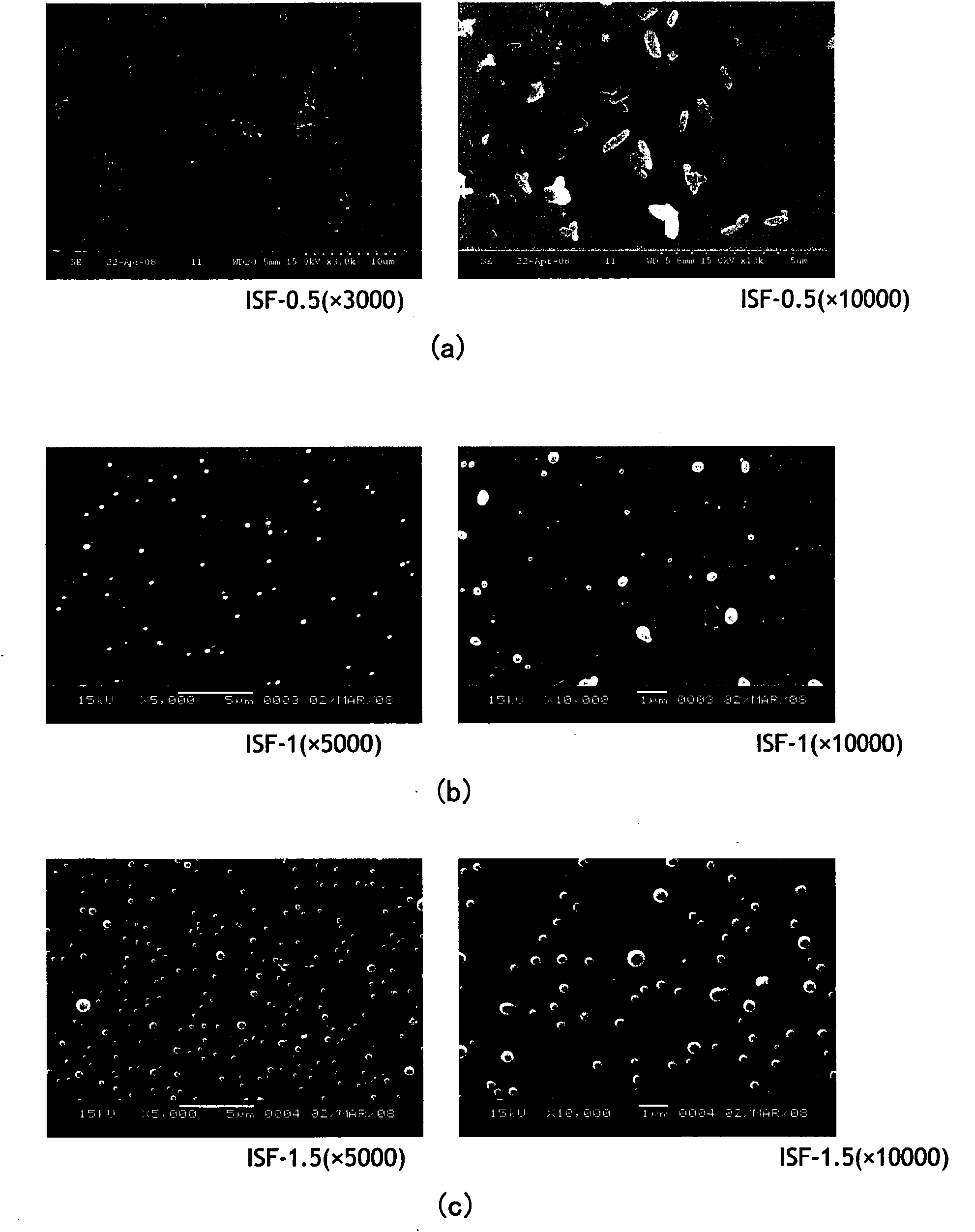

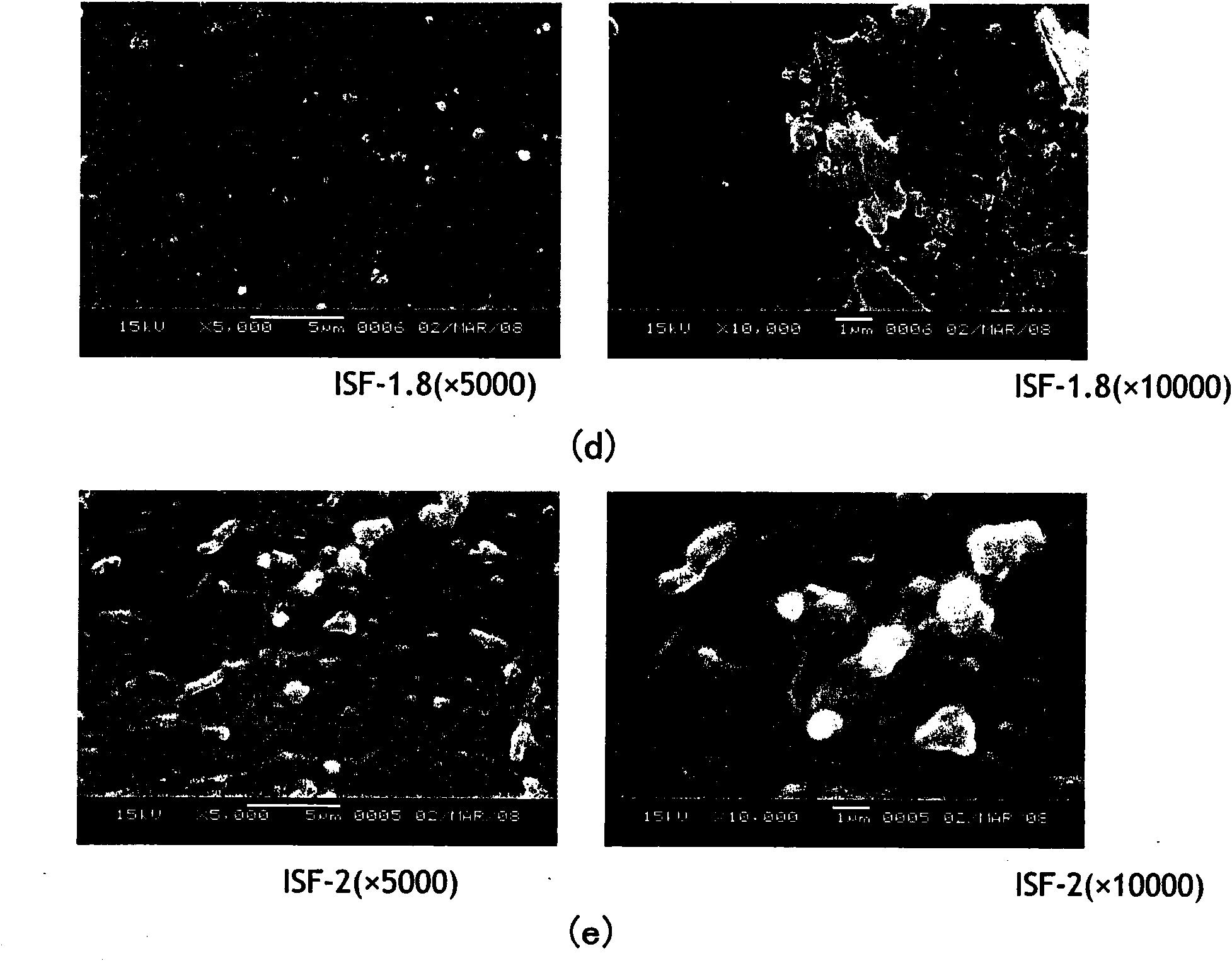

[0030]Add 445.6g of dimethyl terephthalate (DMT), 653.9g of neopentyl glycol (NPG), 163.2g of trimethylolpropane (TMP) and 0.1912g of catalyst zinc acetate (dissolved in 0.96g of water) to the glass for reaction In the container, the temperature was raised to 210°C within 90 minutes, and the temperature was lowered to 80°C when the distillate (methanol) reached the theoretical value (about 145g). After the mixed solution of 69ml of n-butyl titanate and 200ml of xylene was slowly added dropwise under rapid stirring, 381.2g of isophthalic acid (IPA) and 287.6g of adipic acid (AA) were sequentially added while keeping the temperature below 100°C. Slowly raise the temperature to 225°C, during which xylene will be distilled out. When the final distillate (butanol, water and glycol) reaches 95% of the theoretical value (about 370g), the acid value and hydroxyl value of the system are often measured. When The reaction is completed when the acid value reaches 8-12 mg KOH / g and the hyd...

Embodiment 2

[0034] 445.6g dimethyl terephthalate (DMT), 653.9g neopentyl glycol (NPG), 163.2g trimethylolpropane (TMP), 0.1912g catalyst zinc acetate (dissolved in 0.96g water) and 69ml titanium Add the mixed solution of n-butyl acid and 200ml xylene into the glass reactor, slowly raise the temperature to 210°C, and cool down to 80°C when the distillate (methanol) reaches the theoretical value (about 145g). 381.2 g of isophthalic acid (IPA), 287.6 g of adipic acid (AA) were slowly added sequentially under rapid stirring. Slowly raise the temperature to 225°C. When the final distillate (butanol, water and glycol) reaches 95% of the theoretical value (about 370g), the acid value and hydroxyl value of the system are often measured. When the acid value reaches 8-12mg KOH / g. When the hydroxyl value reaches 90-100mgKOH / g, cool down to 130°C. A titanium-based nanoparticle / polyester composite coating with a titanium-based nanoparticle content of 1% was obtained. 1600 g of xylene and butyl acet...

Embodiment 3

[0036] Add 445.6g dimethyl terephthalate (DMT), 653.9g neopentyl glycol (NPG), 163.2g trimethylolpropane (TMP), 0.1912g catalyst zinc acetate (dissolved in 0.96g water) to the glass for reaction In the container, the temperature was slowly raised to 200-210°C, and when the distillate (methanol) reached the theoretical value (about 145g), the temperature was lowered to 80°C. To the reaction system, slowly drop the mixed solution of titanium tetrachloride (37ml) and xylene (100ml) mixed in a certain proportion with a dropping funnel, and then add 381.2g of isophthalic acid (IPA), 287.6g of adipic acid (AA). Slowly raise the temperature to 220-230°C, when the distillate (water, diol) reaches 95% of the theoretical value (about 180g), often measure the acid value and hydroxyl value of the system, when the acid value reaches 8-12mgKOH / g, the hydroxyl When the value reaches 90-100mg KOH / g, the temperature is lowered to 130° C. to obtain a titanium-based nanoparticle / polyester compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com