Preparation process of amorphous silicon film solar battery based on laser etched and crystallized optical film layer

A solar cell, amorphous silicon thin film technology, applied in sustainable manufacturing/processing, circuits, electrical components, etc., can solve the problems of poor stability, low photoelectric conversion efficiency, etc., achieve low cost, easy to form large-scale production capacity, The effect of short energy recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

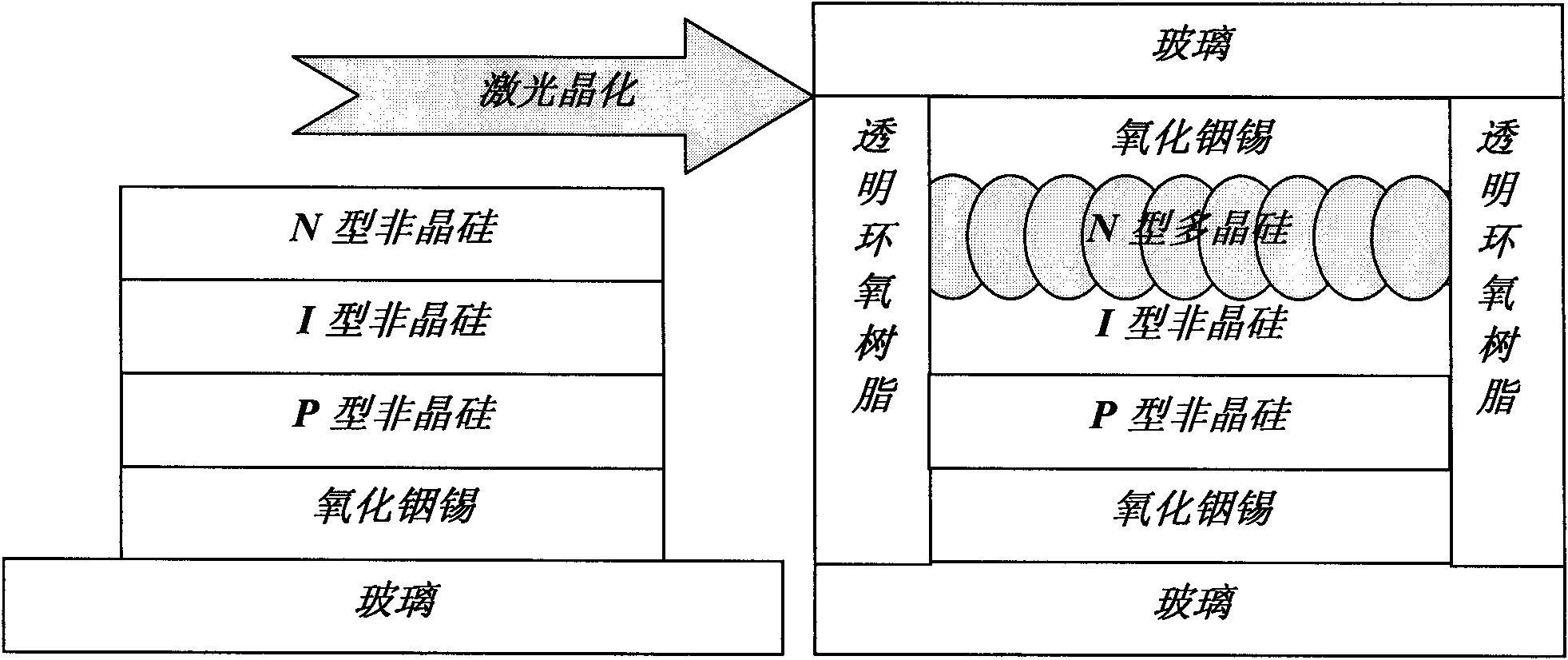

[0025] Embodiment one: the specific process steps of the present embodiment are as follows:

[0026] PECVD is used to prepare a-Si, the RF power is 35W, the power source capacitive coupling is 13.56MHz, the substrate temperature range is 180-250°C, and the gas glow pressure range is below 20Pa. The method includes the following process steps:

[0027] a. Preparation of P-type layer a-Si: Borane B 2 h 6 with silane SiH 4 The mass flow ratio is 0.28%, and the thickness is 30nm.

[0028] b. Type I layer (intrinsic layer) a-Si preparation: silane SiH 4 with hydrogen H 2 The mass flow ratio is 10%, and the thickness is 500 nm.

[0029] c. Preparation of N-type layer a-Si: Phosphine PH 3 with silane SiH 4 The mass flow ratio is 0.55%, and the thickness is 100nm.

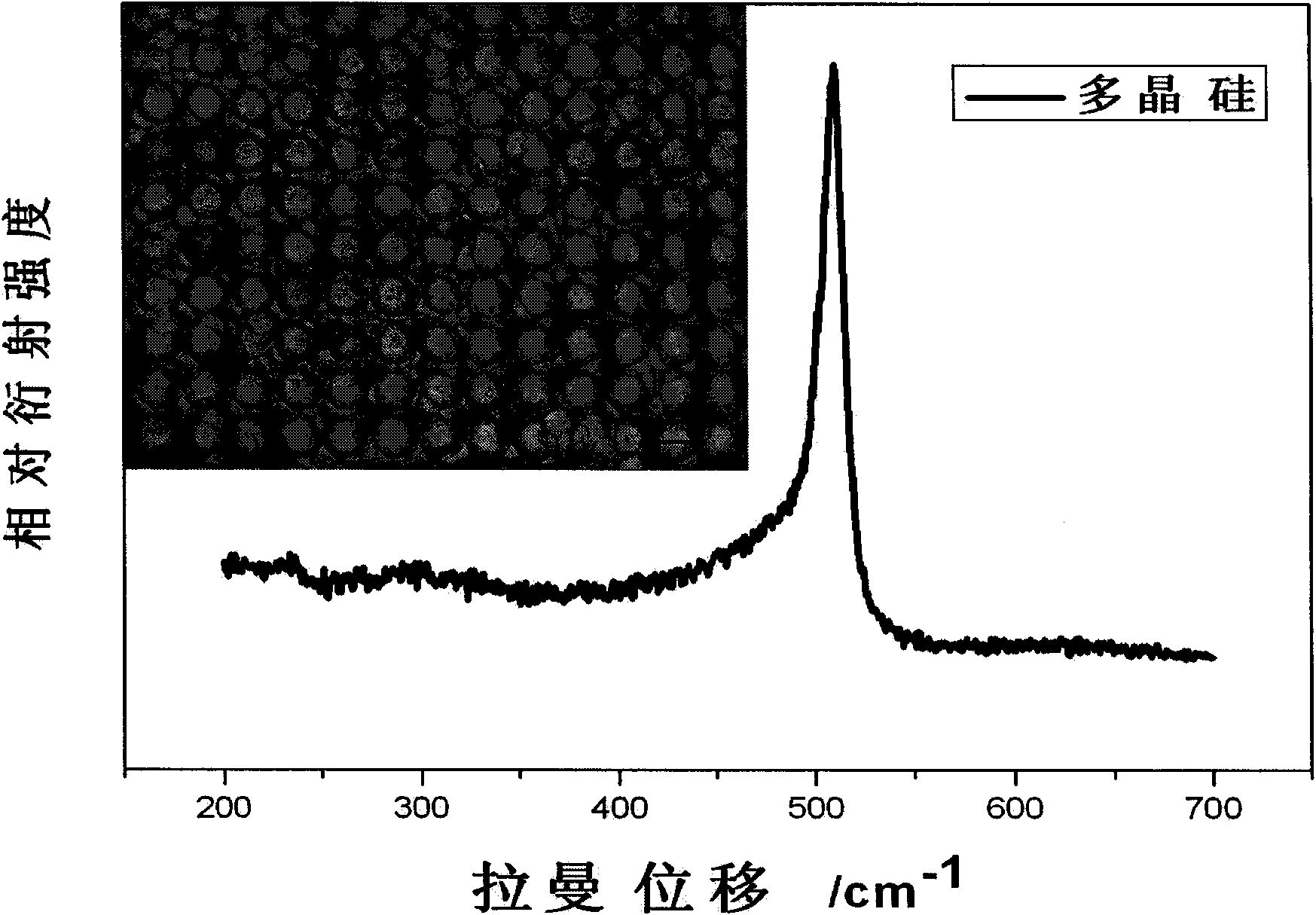

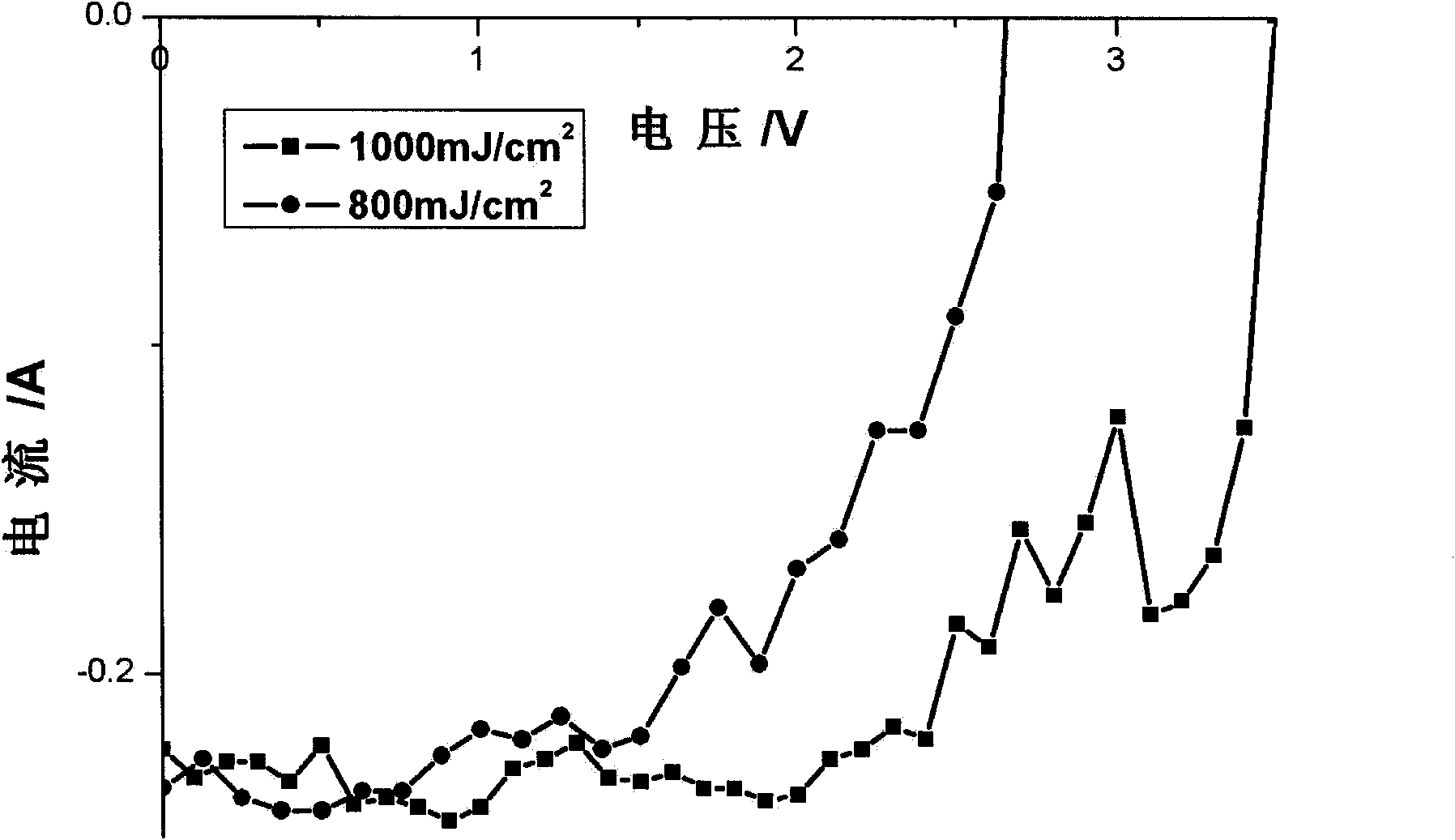

[0030] d. Preparation of the poly-Si layer of the optical thin film layer: use a frequency-doubled Nd:YAG laser with a wavelength of 532nm to irradiate the surface of the sample, and then shape it into a flat-top ...

Embodiment 2

[0033] Embodiment 2: This embodiment is basically the same as the above-mentioned embodiment, the difference is:

[0034] The preparation of the poly-Si layer of the optical thin film layer: the surface of the sample is irradiated with a frequency-doubled Nd:YAG laser with a wavelength of 532nm, shaped into a flat-top green laser by the fly-eye technique, and then etched and crystallized N-type amorphous silicon layer to realize N The type layer is changed from amorphous silicon to polysilicon optical thin film layer. Mainly adjust the laser energy density to control the grain size to achieve the antireflection and antireflection functions of the modulated optical film layer. Now adjust the laser energy density to 1200mJ / cm 2 .

[0035] The amorphous silicon thin-film solar cell of the polysilicon optical thin-film layer that the inventive method makes is fully suitable for the requirement of the photoelectric conversion efficiency of photoelectric solar cell, can be used as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com