Composite material special for automobile engine oil pan and preparation method thereof

A composite material and engine oil technology, applied in engine components, engine lubrication, machine/engine, etc., can solve the problems of low durability work adaptability, durability can not reach the service life, etc., to achieve excellent mechanical strength and dimensional stability properties, excellent long-term and short-term thermal properties, excellent chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

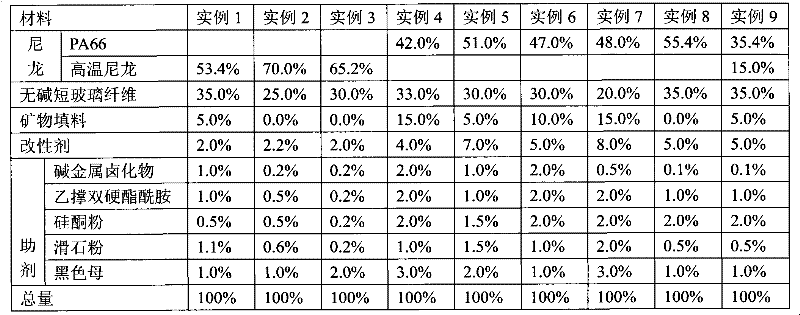

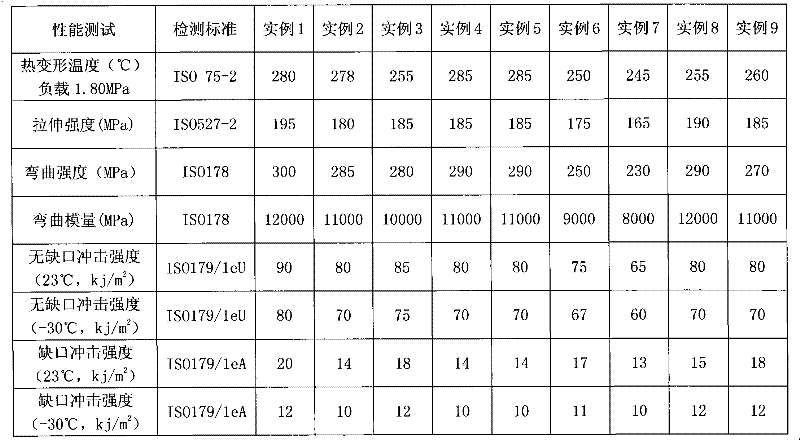

[0055] A special composite material for an automobile engine oil pan, the composite material contains nylon, alkali-free short glass fibers, mineral fillers, modifiers and auxiliary agents; wherein, the nylon is high-temperature nylon PA46; the alkali-free short glass The fiber is treated with a silane coupling agent; the mineral filler is kaolin; the modifier is acrylonitrile-butadiene-styrene copolymer (ABS); the auxiliary agent contains a temperature-resistant anti-aging agent, a lubricant, Nucleating agent and dyeing agent; The temperature-resistant anti-aging agent is a mixture of alkali metal halide cuprous chloride and potassium bromide, and the lubricant is a mixture of ethylene bis stearamide and silicone powder. The nucleating agent is talcum powder, and the dyeing agent is black masterbatch. The mass percentages of the above-mentioned components are shown in Table 1.

[0056] The preparation method of the special composite material for the oil pan of the automobile...

Embodiment 2

[0062] A special composite material for the oil pan of an automobile engine, the composite material contains nylon, alkali-free short glass fibers, modifiers and auxiliary agents; wherein, the nylon is high-temperature nylon PA9T; the alkali-free short glass fibers are treated with silane Coupling agent treatment; the modifier is a mixture of polyethylene (PE) and polyphenylene ether (PPO); the auxiliary agent contains a temperature-resistant anti-aging agent, lubricant, nucleating agent and dyeing agent; The temperature anti-aging agent is a mixture of alkali metal halide potassium bromide and cuprous iodide, the lubricant is a mixture of ethylene bis stearamide and silicone powder, and the nucleating agent is talcum powder; The dyeing agent is black masterbatch. See Table 1 for the weight percentages of the above-mentioned components.

[0063] The preparation method of the special composite material for the oil pan of the automobile engine includes the following steps:

[...

Embodiment 3

[0069] A special composite material for an automobile engine oil pan, the composite material contains nylon, alkali-free short glass fiber, a modifier and an auxiliary agent; wherein, the nylon is high-temperature nylon and is PPA and PA6T; the alkali-free short glass The fiber is treated with a silane coupling agent; the modifier is a mixture of polycarbonate (PC) and polyethylene terephthalate (PET); the auxiliary agent contains a temperature-resistant anti-aging agent, a lubricant, Nucleating agent and dyeing agent; the temperature-resistant anti-aging agent is alkali metal halide cuprous chloride, the lubricant is a mixture of ethylene bis-stearamide and silicone powder, and the nucleating agent is talcum powder ; The dyeing agent is black masterbatch. See Table 1 for the weight percentages of the above-mentioned components. Wherein, the mass percentage of PPA in the composite material is 30%; the mass percentage of PA6T in the composite material is 35%.

[0070] The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com