Preparation method for regenerative polyester staple fiber

A technology of regenerated polyester and staple fibers, which is applied in fiber processing, filament generation, melt spinning, etc., can solve the problems of fiber thickening, strength reduction, and high cost, and achieve improved mechanical properties, enhanced reinforcement effects, and thermal shrinkage. The effect of rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this embodiment, the intrinsic viscosity of recycled polyester bottle flakes is 0.8, and about 5% of recycled polyester foam (viscosity 0.7) is added. The colors of the raw materials are all bright white. The drying temperature is 135° C., and the drying time is 2 hours. After drying, the water content of the slices is reduced to below 40ppm. The system adopts filling and stirring drying, with low drying temperature, short drying time and obvious drying effect.

[0025] Before the polyester raw material is added to the screw spinning machine, add titanium dioxide in an amount of 15%, mix it evenly with a high-speed mixer, and then add it to the screw spinning machine. The spinning speed is 700m / min to make a pre-drawn yarn and reciprocate drop barrel.

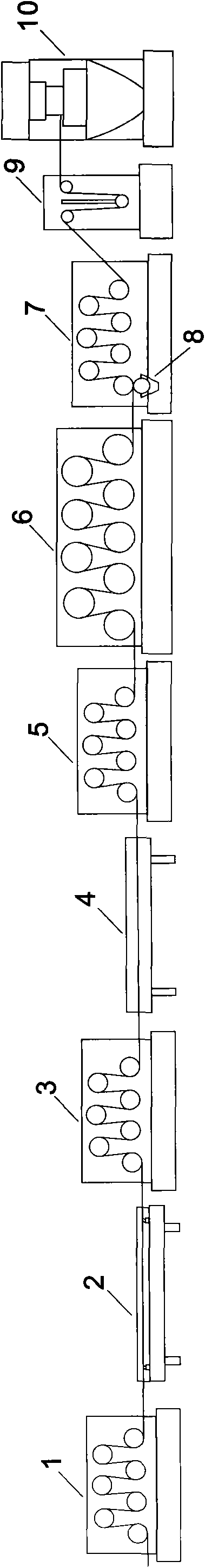

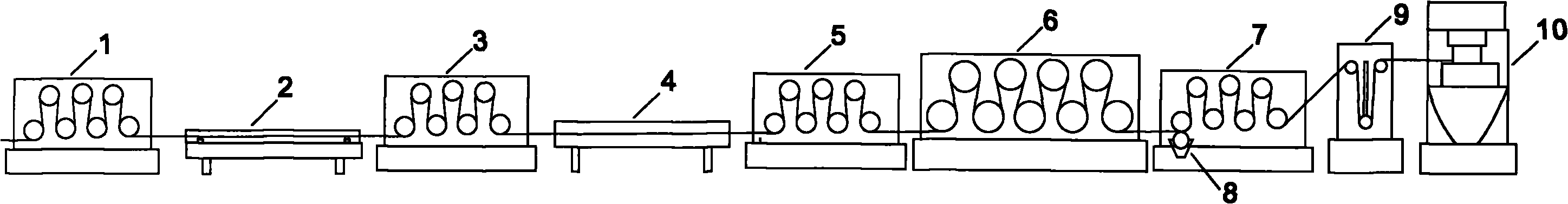

[0026] exist figure 1 In the first stage of drafting, a special fiber finishing oil and preservative are added to the oil tank, the concentration of the oil is 1.0%, the temperature of the oil tank is 68±2℃, and the ...

Embodiment 2

[0032] In this example, the intrinsic viscosity of recycled polyester bottle flakes is 0.75, the color of the raw materials is bright white, the drying temperature is 125°C, and the drying time is 2.5 hours. After drying, the water content of the slices is reduced to below 40ppm. The temperature is low, the time is short and the drying effect is obvious.

[0033] Before the polyester raw material is added to the screw spinning machine, add titanium dioxide in an amount of 15%, mix it evenly with a high-speed mixer, and then add it to the screw spinning machine. The spinning speed is 700m / min to make a pre-drawn yarn and reciprocate drop barrel.

[0034] exist figure 1 In the first stage of drafting, add a special fiber finishing oil and preservative to the oil tank, the concentration of the oil is 1.0%, the temperature of the oil tank is 70 ℃, and the draft ratio is 3.5 times; The temperature is 140°C, the draw ratio is 1.15 times; the draw ratio is 86%.

[0035] In the ten...

Embodiment 3

[0040] In this embodiment, the intrinsic viscosity of recycled polyester bottle flakes is 0.80, and about 20% of recycled polyester foam (viscosity 0.7) is added. The colors of the raw materials are all bright white. The drying temperature is 135° C., and the drying time is 2 hours. After drying, the water content of the slices is reduced to below 40ppm. The system adopts filling and stirring drying, with low drying temperature, short drying time and obvious drying effect.

[0041] The polyester raw material is added to the screw spinning machine for spinning, and the spinning speed is 700m / min to make a pre-drawn yarn and reciprocally fall into the barrel.

[0042] exist figure 1In the first stage of drafting, add a special fiber finishing oil and preservative to the oil tank, the concentration of the oil is 1.5%, the temperature of the oil tank is 70 ℃, and the draft ratio is 3.5 times; The temperature is 120°C, the draw ratio is 1.15 times; the draw ratio is 86%.

[0043]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com